Anpeng Heavy Duty Anti-clogging Screen

(2024年)https://www.apscreens.com/products/anti-clogging-screen/

Independent wires are bound together horizontally with wire wefts woven in between. This type of flexible connection allows the wires to vibrate freely at different frequencies preventing material from accumulating between the wires. It effectively screens all kinds of damp, sticky, hard-to-screen materials in the mining, quarry, aggregate processing, sand and gravel industry.

Anpeng

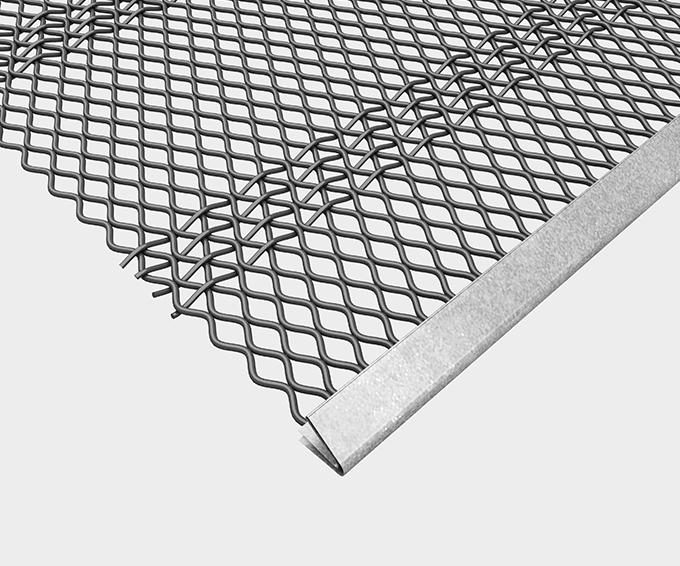

Anti Clogging Wire Mesh

is available in Diamond opening, Triangle opening and Harp opening.

Heavy-duty Metal Screen Material

High-tensile steel and stainless steel are two common materials used for manufacturing heavy-duty metal screens due to their excellent mechanical properties and resistance to corrosion. Here's some information about each of these materials:

High Tensile Steel:

High-tensile steel, also known as high-strength or high-performance steel, is characterized by its ability to withstand heavy loads and stresses without permanent deformation or failure. It has a high yield strength and ultimate tensile strength.

Advantages:

Excellent strength-to-weight ratio: High tensile steel provides exceptional strength without excessive weight.

Resists deformation: It can withstand significant loads without bending or warping.

Suitable for heavy-duty applications: High-tensile steel is commonly used in construction, mining, agriculture, and manufacturing.

Applications: heavy duty steel mesh screen made from high-tensile steel are often used in mining equipment, agricultural machinery, construction machinery, and industrial sieves.

Stainless Steel:

Stainless steel is an alloy composed primarily of iron, chromium, and other elements. It is known for its resistance to corrosion, staining, and rust, making it an excellent choice for outdoor and corrosive environments.

Advantages:

Corrosion resistance: Stainless steel does not corrode easily, making it ideal for outdoor and marine applications.

Hygienic: Stainless steel is easy to clean and maintain, making it suitable for applications where cleanliness is crucial.

Aesthetic appeal: Stainless steel has a sleek and modern appearance.

Applications: Stainless steel screens are used in a wide range of heavy-duty applications, including architectural projects, food processing equipment, chemical processing plants, marine hardware, and outdoor infrastructure.

Features of Anti-Clogging Wire Mesh

1

Prevent clogging and blinding

2

Top Grade high-tensile steel and stainless steel

3z

Various openings and sizes.

4

Easy installation and quick maintenance

Service life of heavy duty metal mesh screen

The service life of a woven screen depends on three core factors:

1.

The quality of the steel: Considering the importance of carbon content on the wear resistance, Anpeng requires at least 0.5% carbon content in high tensile steel.

2.

The design of screens: is another important factor that determines the wear life of screens; Anpeng provides efficient solutions that adapt to your equipment and your specific applications, which improve wear life and performance.

3.

The quality of the screening machine: The correct setting of the screening machine on the screening machine is critical to its service life. It is important to make sure that the tensioning system or bracket is in good condition and that the hooks are properly tightened to avoid any breakage or premature wear.

As one of the most professional industrial screens manufacturers, we provide heavy duty metal screen material, heavy duty metal screen mesh, industrial mesh screen and etc. For more information, please feel free to contact us!

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント