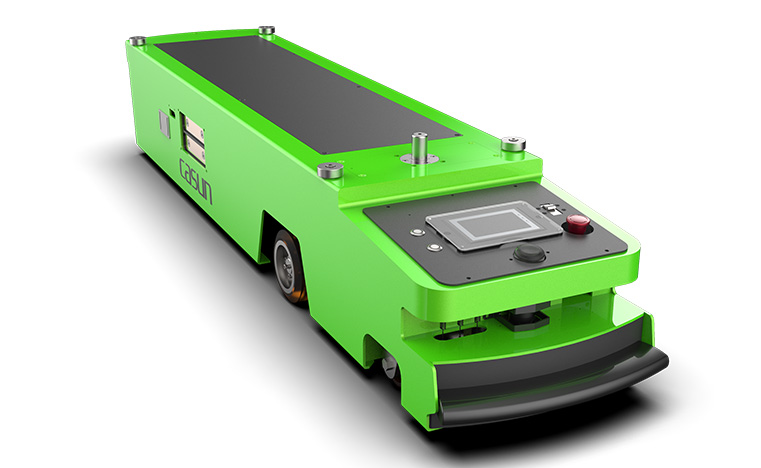

F10 Unidirectional Latent Traction AGV

(2022年10月09日)https://www.casun-agv.com/products/f10-unidirectional-latent-traction-agv/

F10 is a mini stacking forklift AGV towing with compact design, moving speed can reach 72m/s with a full load, its lifting height can reach 1600mm maximum, workable in narrow logistics aisle (Min width can be 900mm, normally the mini fork AGV needs 1200mm width for regular forklifts), which help increase the utilization ratio of the working site.

Parameters of F10 Unidirectional Latent Traction AGV

NavigationLaserLifting height1600mm

Vehicle dimensionsL1650*W854*H2295(mm)Driving methodSteering wheel

Moving directionMove forward/backward, turn left/rightCharging methodSide charging

Load capacity1000KGBatteryLithium battery

Rated speed0-72m/minCommunicationWiFi/5G

Turning radius1500mmSafety alarmLight+Audio

Guidance accuracy±10mmSafety detecting range≤3m(adjustable)

Stopping accuracy±10mmSafety ProtectionsFront obstacle detection sensor+Mechanical anti-collision bumper+Emergency stop switch

Core Advantages of F10 Unidirectional Latent Traction AGV China

01

Low requirements on site space

AGVs can work in narrow aisles and do challenging jobs like 90-degree corner turning or 180-degree in-situ rotation & turning around in narrow space with width of only 854mm ~ 900mm.

02

On-site high utilization rate

Storage capacity can be increased by 20% when placing goods in parallel if compared with ordinary forklift trucks.

03

Elevators linkage

AGVs can link with ordinary elevators, can realize 2 forklifts synchronized in & out of the elevator and greatly improve operation efficiency.

04

Multi floors crossing

Workable across floors with similar map scenario, greatly meet the requirements for material transfer across floors.

05

High positioning accuracy

The 1st time positioning accuracy can reach ±10mm,the 2nd positioning accuracy can reach ±5mm.

06

Strong environmental self-adaption

It can be quickly applied without on-site transformation.

07

Easy to use

Easy to operate according to scheduling instructions, without manual intervention in the production process.

08

Malfunction self-inspection

With perfect malfunction self-check function, and remote fault diagnosis and self-recovery function.

09

Charge automatically

The equipment will charge automatically when the power is detected to be in low status, in order to rise productivity, its response time can be 24 hours per day.

10

Multiple security protection

With laser obstacle detection sensor/mechanical anti-collision device/acoustic-optic warning for protection.

We can offer kinds of automated guided robots for sale, if you have needs, please contact us.

As one of automated guided vehicle manufacturers, we will do our best to meet all the needs of customers.

- このできごとのURL:

コメント