Poly (Polycrystalline Diamond Powder)

(2022年09月29日)https://www.superabrasivespowder.com/products/poly-polycrystalline-diamond-powder.html

Buy diamond micro powder from E-Grind.

E-Grind produces high-quality polycrystalline diamond micro powder. Available sizes of diamond micro powder are as below:

0-0.15, 0-0.2, 0-0.35, 0-0.5, 0.25-0.35, 0-1, 0-2, 2-4, 3-6, 3-7, 4-8, 4-9, 6-10, 6-12

Custom-made sizes are also available upon customers' demands.

Properties of Polycrystalline Diamond Powder

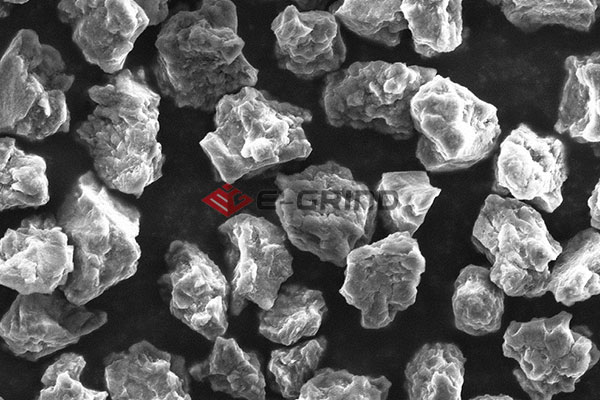

Detonation-synthesized polycrystalline diamond micro-powder

The structure resembles the rare natural polycrystalline black diamond, metallic-grey, superior toughness, self-sharpening.

The lapping and polishing efficiency of the detonation-synthesized polycrystalline diamond micro-powder is 2 to 4 times better compared with that of the mono-crystalline diamond that is naturally occurred or synthesized via the static pressure method, Silicon Nitride, Corundum, and other abrasive materials.

Polycrystalline diamond micro-powder allows the manufacturing of the smoothest surface possible:

a. When using polycrystalline diamond micro-powder of size 2-4micron to the polishing surface, Ra (roughness) < 1.6nm

b. When using polycrystalline diamond micro-powder of size 0-0.5micron to the polishing surface, Ra (roughness) < 1.3-1.4nm

c. When using polycrystalline diamond micro-powder of size 0-0.125micron to the polishing surface, Ra (roughness) < 0.1nm

Polycrystalline diamond can maintain its dull mono-crystalline structure by releasing the outer layer, hence will produce the most scratch free surface possible.

When applied to the surface of a workpiece (for example, the inner surface of a cylinder in an engine) via chemical plating method, the wearability of the surface is superior to that of a surface treated with any other materials.

Via after-sinter technique, polycrystalline diamond micro-powder can be turned into polycrystalline diamond particles of a large size that are highly valuable in a variety of industries.

Application of Polycrystalline Diamond Powder

Lapping and polishing a variety of surfaces that require superior smoothness.

Improving the wearability of a mechanical component

Via after-sinter technique can be applied in a variety of industries.

Can be made into liquid abrasives, gel abrasives, and many other types of abrasive tools that are capable of ultra-fine lapping and polishing tasks.

Polycrystalline Diamond Powder Industries

Computer industry: Read/Write head lapping, rigid disk media texturing

Gem polishing

Semi-Conductor, electronic ceramic, optical instruments

Used as anti-wearing media in special rubber and plastics

Chemistry catalyst, Biomedicine

With more than 20 years experience, E-Grind is a professional polycrystalline diamond micro powder supplier and manufacturer, we provide all sizes of Poly (Polycrystalline diamond micron powder) with high removal rate, superior surface finishing, and long using life. Our Quality Control Department keeps strict and careful control of raw material from lot to ensure quality basis. All the products are tested during production and after processing, to make sure of quality consistency and quality traceability. The test report is attached to each shipment for customers reference.

E grind is a professional superabrasive ltd, we provide superabrasive, monocrystalline vs polycrystalline diamond, diamond powders and etc. For more information, please feel free to contact us!

- このできごとのURL:

コメント