Two Shot Molding

(2022年)https://www.key-plast.com/two-shot-molding/

Two component injection molding, also called double shot injection molding, dual shot injection molding, multi shot injection molding or 2k moulding is one category of injection molding using two different thermoplastic materials to produce injection molded parts in two colors or two components in the two shot injection molding process to produce 2 shot molding in large quantities quickly, economically and efficiently. Multi shot molding has characteristics as below:

Two shot injection molding, co-injection, two-color and muti-component injection are all variants of advanced molding techniques.

A combination of hard plastics and soft materials.

Two-step process is executed in a single press cycle.

Combine two or more components to eliminate additional assembly costs.

Keyplast plastic two shot molding company and two shot molding factory also provides overmolding injection molding, insert injection molding and materials used in injection moulding with cheap prices. Contact us now!

Two Shot Molding Process

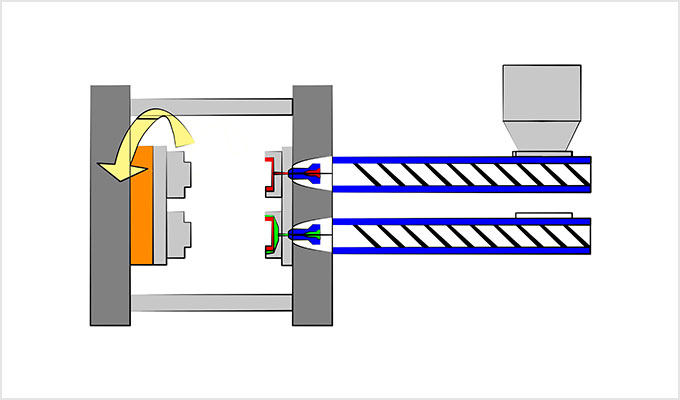

Two shot injection molding has two stages in the whole process.

Firstly one shot of materials is injected into a mold and cooled to form a solid part. Secondly, the mold opens and rotates 180 degrees and then closes. The second shot of materials is injected into the mold, through or around the first molded part. After sufficient cooling, the mold opens and the multi-resin molded part is ejected. 2 shot moulding has key factors as below:

Melting temperature for the materials

Wall temperature for the mold

Injection speed for the molded parts

Delay time between injections

Temperature of the components

Two Shot Injection Molding Design Guide

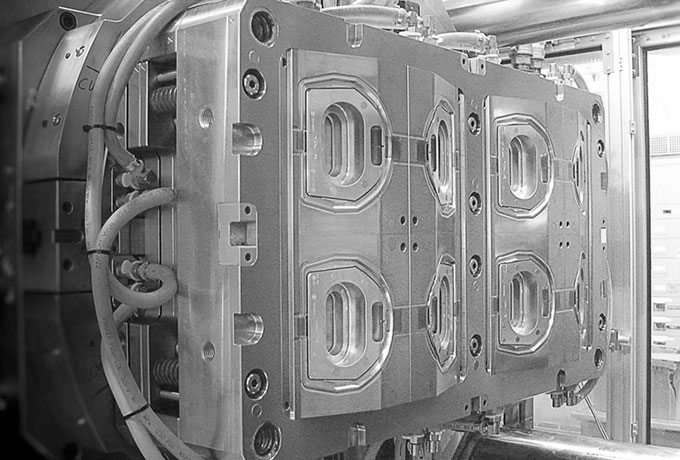

The mold used in two shot molding consists of different tool sets. In rotating platen settings, these two shot china polycarbonate injection molding tools share the same core, but different cavities. The runner must be designed to close during its inactive forming step.

Wall thickness is an important two shot molding design consideration when designing parts for a number of reasons:

Due to the molding pressure from the second step, the substrate wall should be thick enough to withstand the force without collapsing.

Walls should not exceed traditional thickness guidelines to produce effects attributable to irregular cooling.

To ensure accurate and thorough flow of 2k molding material into all parts of the cavity, the wall thickness should not fall below a certain minimum value.

Ideally, materials should be injected in a certain order, taking into account the following factors:

The first shot should be the harder plastic of the two.

If transparent and opaque materials are used, inject transparent materials first.

Generally speaking, the material with higher temperature is injected first.

For mold frame and insert design:

Make sure the mold can be rotated 180 degrees.

Any insertion should be symmetric.

The push rod plate and thimble are stabilized by a return spring to prevent damage during mold rotation.

The cooling system of double shot molding must be able to function adequately on the first and second shots.

Advantages Of Two Shot Injection Molding

Cmpared to other plastic molding methods , the most important bent of 2 shot molding is more economical to manufacture multi-components in the injection molding process as below

01

Part Consolidation

Lower multi-components cost, including the developing, engineering and validation costs related to each additional part and savings in production and assembly.

02

Improved Efficiency

Improvement of effectiveness and efficiency, allowing one single mold but multi-components to be injected, thus simplifying the abor operations and eliminating secondary operations , such as further needs for welding or connecting multi-components after plastic injection molding process of double injection molding.

03

Improved Quality

Improvement of quality and function of double shot molding, permitting lower tolerances than other molding processes, requiring high-qualified accuracy and repeatability and reducing the rate of defect parts.

04

Complex Moldings

Create new mold designs of two shot moulding and allow manufacturing more complex mold designs, Iike multi-metenvels, multi-components or multi-colors that can not be achieved by other molding processes.

Two Shot Injection Molding Applications

As one of important injection molding supplies, two shot molding/double shot moulding is ideal for the fields as below:

Multi material injection molding or multi color injection molding.

Moveble segments or components.

Soft touch handles, grips and other components.

Vibration and noise dampening and isolation.

If you want to watch two shot molding video, please visit our website.

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント