Plastic Injection Mould Tooling

(2022年07月25日)https://www.key-plast.com/plastic-mold-making/

Plastic molds are tools that are matched with plastic injection mold making machines in the plastic processing industry to give plastic moulding products a complete configuration and precise dimensions. Due to the wide variety of plastics and processing methods, and the complex and simple structures of plastic injection molds making machines and plastic products, the types and structures of plastic molds are also diverse.

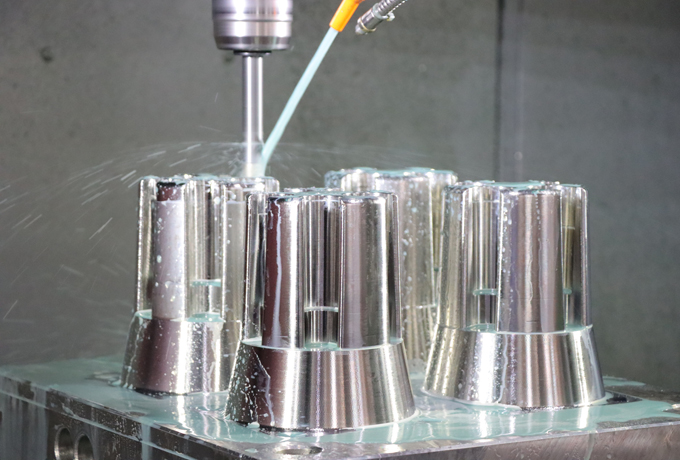

Mold Making

As a professional injection molding supplier, we complete all plastic injection mould making, from cutting materials to cavity carving, and then to the final assembly. We have advanced high-speed milling machines, electric discharge machines, wire cutting machines, and engraving machines to ensure that the machining accuracy can meet the requirements.

Mold Trial

Generally, the mold is not directly regarded as the final product when it is designed, because it will have such or other defects after it is produced. However, this type of defect There is no guarantee that they will be completely avoided before manufacturing. During the manufacturing process, there may be phenomena that cannot be stored and processed. Therefore, it is necessary to go through the trial model, and then analyze, evaluate and optimize the samples produced by the trial model to meet the requirements. High quality requirements. However, most of the defects of plastic mould tooling products are caused during the plasticization and injection molding stages, and may also be caused by improper manufacturing of plastic molds. Therefore, in order to avoid product defects caused by mold design in injection molding process steps, it is necessary to analyze when making molds. Mold design and process parameters.

Sample Confirmation

The acceptance of the part shall be carried out at least 16 hours after the completion of the molding of the plastic part or the required post-treatment.

1. Inspection of product matching size

The matching dimensions of injection molding mold products refer to the matching dimensions between products or between injection moulding products and related components, including partial matching dimensions and overall relative position dimensions.

2. Trial assembly inspection

When the inspections of basic dimensions, external dimensions, and matching dimensions are completed and the design requirements are basically met, trial assembly inspection can be carried out. This is a very important means in product inspection. It can verify the matching dimensions and verify the space surface.

3. Injection molding quality inspection

When the pre-installation meets the requirements, the apparent quality of the part needs to be comprehensively inspected. At this time, the apparent quality refers to whether the apparent quality meets the requirements under the condition that there are no common defects.

As one of the most professional custom injection molding companies, Keyplast offers plastic injection molding service, plastic injection molding service, custom injection molded products, custom plastic injection molds, plastic mold manufacturing, plastic injection mold tooling, etc. Keyplast sincerely invite you to visit our company and establish long-term business relationship with us.

- このできごとのURL:

コメント