PCB Capability

(2023年06月12日)https://www.greenpcba.com/pcb-capability/

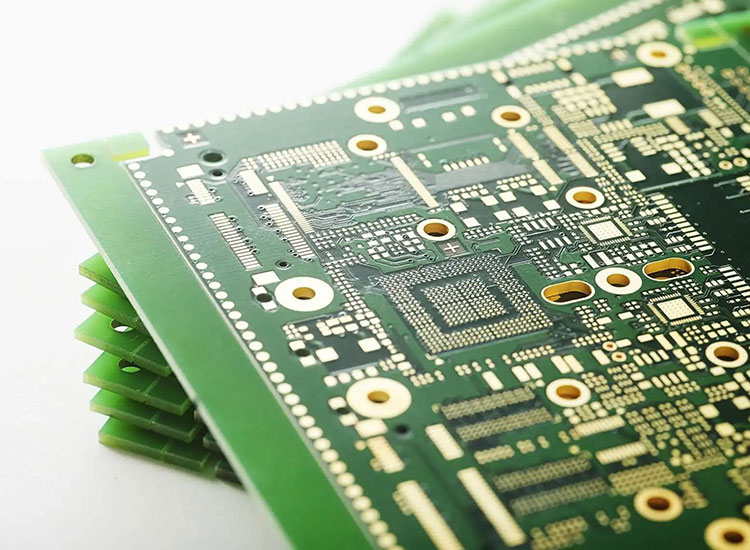

PCB Capability

GreensTone has successfully served customers with PCB manufacturing service in communication, industial devices, new engrgy, power supply, sensors, smart home applications control, smart industial control , medical devices and security control device and so on.

GreensTone PCB Quality Control

1. PCB Files Checking Before manufacturing

For every orders we recieved, Gerber files should be checked by our PCB engineers before sending to production. Engineers would help to check the board edge clearance, drilling, pad spacing, impedance and routing. if the engineer finds a problem with the file or something can't be optimized, our engineers will contact the customer to confirm the files again.

2. Raw Material Guarantee

The quality of the raw materials determines the quality of the finished products. GreensTone has been working with leading suppliers in the industry,and apply materials as to international standards and customer requirements, such as Rogers, Shengyi, KB (kingboard) sheet, Rohm&Haas, TAIYO for solder mask ink.

3. The Good Performace Production Equipment

To ensure the quality and reliability of PCB products, GreensTone continuously introduces advanced equipment to improve their pcb fabrication capabilities, including:

Automatic solder mask production line

LDI exposure machine

Fully automatic PCB etching equipments line

Fully automatic PCB testing machine line

Fully automatic electroplating line

Automatic silkscreen printing production line

4. Quality Inspection Method

Comply with ISO9001:2015 requirements

Production processes are in line with IPC standards

Basic visual inspections

Rigorous electrical tests.

Flying Probe Testing

AOI (Automated Optical Inspection)

Copper Thickness Tester

Specification of PCB Capability

ItemPCB Capability

Layers1-8 layers

Thicker Copper1- 4OZ

Products TypeHF(High-Frequency)&(Radio Frequency) board, Impedance controlled board , HDI board, BGA& Fine Pitch board

Solder MaskRed, green, yellow, white, blue, black, Matt black

Base materialFR4, HI-TG, heavy copper and so on

Finished SurfaceConventional HASL, Lead-free HASL, Falsh Gold, ENIG (Immersion Gold)OSP(Entek), Immersion Tin, Immersion Silver, Hard Gold

Technical SpecificationMinimum line width/gap: 3.5/4mil(laser drill)

Minimum hole size: 0.15mm(mechanical drill)/4mil(laser drill)

Minimum Annular Ring: 4mil

Max Copper thickness: 4OZ

Max Production size: 900×1200mm

Board Thickness:D/S: 0.2-7.0mm, Multilayers:0.40-7.0mm

Min Solder Mask Bridge: 0.08mm

Aspect ratio: 15:1

Plugging Visa capability: 0.2-0.8mm

TolerancePlated holes Tolerance: 0.08mm(min±0.05)

Non-plated hole tolerance: 0.05min(min+0/-0.05mm or +0.05/-0mm)

Outline Tolerance: 0.15min(min±0.10mm)

Insulating resistance: 50 ohms (normality)

Peel off strength: 1.4N/mm

Thermal Stress test: 2650c,20 seconds

Solder mask hardness: 6H

E-Test voltage: 500V+15/-0V 30S

Warp and Twist: 0.7% (semiconductor test board≤0.3% )

SilkscreenWhite, Black, None

PanelizationV-scoring,

Tab-routing,

Tab-routing with Perforation (Stamp Holes

OthersFly Probe Testing (Free) and A.O.I. testing(free), ISO 9001:2008 , UL Certificate

As one of electronics assembly companies, we can offer sorts of related products for sale, if you have needs, please contact us.

- このできごとのURL:

コメント