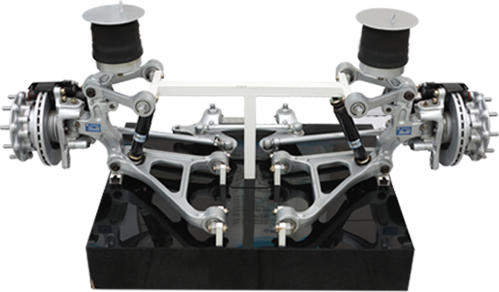

INDENPENDENT AIR SUSPENSION SOLUTION

(2024年04月24日)https://www.kommangroup.com/independant-air-solution/

Overview of Komman Independent Air Suspension

Independent air suspension means that the axle is divided into two sections, the wheels on each side are individually suspended under the frame or body through elastic elements, and the middle section is fixed to the frame or body. At present, double wishbone type air suspension system in automobile is widely used in buses. Komman independent airbag trailer suspension products have a competitive advantage in the market. Our air bag suspension supplier can provide customers with airbag independent suspension solutions with maximum axle loads ranging from 3 tons to 7.5 tons.

Overview of Komman Independent Air Suspension

Advantages of Independent Air Suspension

When one wheel bounces, the other wheel is not affected. The left and right wheels bounce independently and are not related to each other, which can reduce the tilt and vibration of the frame and body when driving on uneven roads, And it helps to eliminate the phenomenon of continuous deflection of the steering wheel, and the stability and comfort of the vehicle are good.

Reduce the non-spring bearing mass, thereby reducing the impact load on the suspension, and improving the ground adhesion of the wheels, which can increase the average driving speed of the bus.

Due to the use of a disconnected axle, the engine position can be lowered and moved forward and the center of gravity of the bus can be lowered, which is conducive to improving the stability of the bus. A softer spring with low stiffness can be used to reduce the vibration frequency of the vehicle body to improve driving comfort.

Through design optimization and matching, the suspension guiding mechanism and the steering rod system can be optimized, so that the vehicle has excellent kinematics, reduces the movement interference between the rod systems, improves the tire adhesion, and reduces tire wear.

The system module can be directly assembled by the OEM after debugging, thereby reducing the production cost of the OEM's logistics and assembly adjustment.

Protection of the road surface: Compared with the traditional commercial vehicle suspension, the impact on the road surface can be reduced by about 25%.

Komman Product Research and Development Capabilities

Komman has a strong R&D team and has introduced RDM, an R&D management system, and PDM, a product data management system. Based on APQP, the R&D projects are grouped and hierarchically managed, and the relevant departments are coordinated to achieve all-around real-time monitoring of the project. At the same time, it uses AUTOCAD, SOLIDWORKS, ADAMS, CATIA, and other professional system analysis software to conduct multi-dimensional analysis of products through finite element analysis, system dynamics analysis, control system analysis, and other technologies to ensure the quality of the air bag suspension wholesale design solution.

R&D Technology Center

3D design: Komman uses 3D interference analysis technology to truly simulate the positional relationship between the parts during the jump, jump, and roll of the axle, avoiding the interference of parts during the product operation, improving the design quality, and optimizing the design solution.

Finite element analysis of part structure: Through finite element analysis technology, the working stress, strain, and displacement of the designed product can be grasped, and the optimized design and lightweight design of structural parts can be carried out at the same time to improve the reliability of the product and reduce the product development cycle and development costs.

System dynamics analysis: Use ADAMS system dynamics simulation software to analyze the movement relations and dynamic forces of various parts of the system during the movement process, and optimize the system design scheme.

As a professional air ride manufacturers, Komman has high-quality bus air suspension for sale. Welcome to contact us if needed.

- このできごとのURL:

コメント