Precision CNC Turning Company

(2023年01月29日)https://www.ljzcncmachining.com/services/cnc-turning/

Precision Multi CNC Turning Service

One-Off Prototype to Massive Production

100% Quality Guaranteed

Precision CNC Turning Factory

What is CNC turning?

CNC Turning is a machining process primarily used to manufacture cylindrical parts, which is a highly precise and demanding subtractive machining process for precision cnc turning supplier. It involves placing the cutting tool against a turning workpiece to remove materials and give the desired shape. Pieces of material (a piece of relatively rigid material such as metal and plastic) are held in a chuck as a machine tool is fed to the piece to cut away excess material to produce the desired shape with precise diameters and depths. LJZ is a professional china cnc turned components manufacturers dedicated to providing premium turning services china, we can provide you relevant services.

Our CNC Turning Service

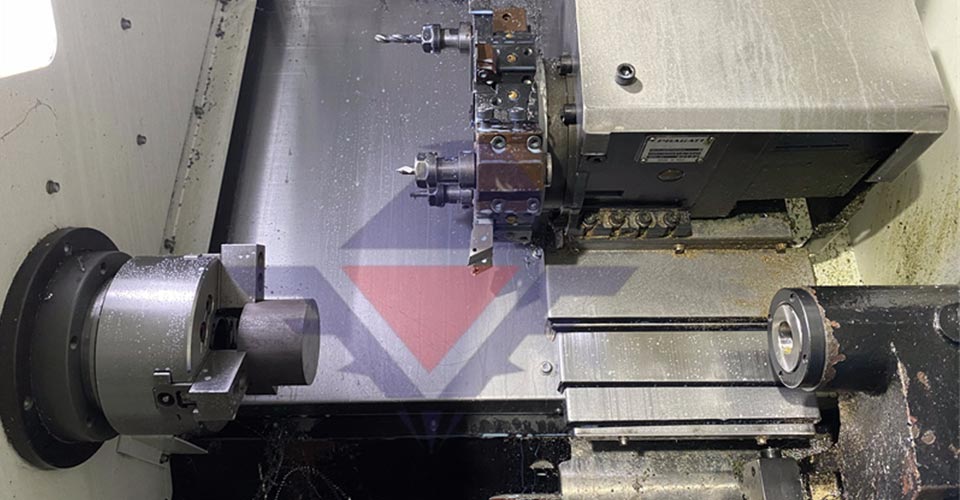

At cnc turning supplier LJZ, we have invested state-of-art mill and turn equipment to improve efficiency and ensure accuracy of complex turned parts. As the picture shows, you can see our large and professional china cnc turned components suppliers. In addition, combined with our advanced programming and engineering technology, the turning time in turned parts can be accurate to every second.

As an excellent precision cnc turning components supplier, our swiss turning machines are from Japan Star, which can maintain the consistency of accuracy and efficiency in 24-hours-working a year. Our monthly everage Swiss CNC turning production capability is 1, 000, 000pcs, which proves that we are a truly excellent cnc turning machining parts supplier.

Discover our precision CNC precision turning/lathing/machining service for sale at LJZ, a reliable precision CNC turning manufacturer in China. Material of our CNC precision turned parts/components/products can be aluminum/stainless steel/brass/copper/titanium and other metal. LJZ cnc precision turning supplier offers wide selection for you. To choose the best cnc turned part supplier, E-mail Us Now!

Large CNC Turning Services of LJZ

Our experienced and professional programming team and operators have been proficient in various operations of precision turning, which includes:

BoringDrilling

KnurlingReaming

GroovingThreading

Hard TurningTapered Turning

With large cutting depth and fast work piece speed, the efficiency of CNC machining turning is usually several times that of grinding. And the auxiliary time of precision CNC turning by LJZ factory is short. In the same productivity, turning machine has the benefits of low equipment and auxiliary system cost. Besides, precision CNC turning service by LJZ, a professional CNC turning company, ensures overall machining accuracy and is a rather flexible processing method.

Benifits of Our CNC Turning Service

One-off rapid prototype part can be created as fast as in one day

Long-term run high volume CNC turning production

ISO 9001 Certified

PPAP and FMEA for automotive clients

Automatic machinery, experienced engineers, and 100% QC assurance

CNC Milling vs CNC Turning

Turning and milling are two typical cutting processes in CNC machining. So, what's the difference between them?

Turning is the way in which rotating materials contact tools, and processed the material.

Milling is a way to process fixed materials by rotating tools.

Turning is good at processing round parts: because lathe processing is carried out by rotating materials, the produced parts are usually be cylindrical, conical or spherical. LJZ's lathe is not only good at processing round, but also can process the outer diameter and tapping inner diameter.

Milling is good at machining complex parts: the components of the milling machine include the spindle for installing and rotating the tool, and the workbench for clamping (fixing) materials. Due to the milling machine cuts materials by linearly moving the worktable while striking the rotating tool, the processed parts can usually combine high precision and complexity. LJZ's milling engineers are good at plane and groove cutting. They can perfectly realize 1:1 mechanical engineering project parts easily.

Types of Turning Tools

According to different purposes, turning tools can be classified as follows:

1. Internal and external turning tools for external turning, internal hole turning and end face turning;

2. Grooves and cutting tools used for grooving the outer circle, inner hole and end face;

3. Internal and external thread turning tools for turning external and internal threads;

4. Make the cutting edge into a profiling tool similar to the shape of the workpiece.

CNC Turning FAQs

CNC Turning Process

CNC turning in machining is a process for cylindrical parts making. During the process, the cutting tool runs in a linear way, and at the same time, the work piece rotates. The rotation of different materials like metal and plastic is achieved through computer numerical control. CNC turning can be employed inside or outside the work piece for the manufacturing of small turned parts.

What is the difference between CNC turning centers and CNC lathes?

What parts can be made with CNC turning?

What parts can be made by CNC milling?

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント