China Aluminum CNC Service

(2023年01月29日)https://www.ljzcncmachining.com/aluminum-machining/

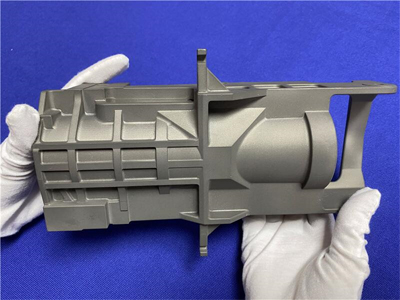

CNC Aluminum Machining Services

One-Off to Million, Machining of Aluminium Alloys

Global Delievery, Custom Aluminum Parts Manufacturer

Aluminum Machining Suppliers

Aluminum CNC machining is a great option for CNC machining. Aluminum alloy materials are favored by engineers in various industries, and aluminum machined parts are commonly used in CNC machining due to its high machinability. Aluminum can be quickly and easily cut by machine tools, and deforms less which leads to higher accuracy. China aluminum parts machining is widely used to create specified precision parts in various industries today.

Aluminum machining supplier LJZ offers a complete China aluminum machined service. As one of the most professional china aluminum machining manufacturers in the world, we can produce complex china machining aluminum parts with different types of Aluminum.

Aluminum Machining China Benefits

Due to the good fluidity and plasticity of aluminum alloy, casting on die casting machine, aluminum parts machining die casting machine CNC machining processing a variety of complex shapes, which can produce higher precision and surface quality. To a large extent, the castings and China aluminum machining services or custom China aluminium machining part are great, and also save electricity, metal materials, and labor costs. Choose China aluminum machining manufacturers, We can offer you cheap custom cost of machining aluminum.

Choose The Reliable China Aluminum Machining Parts Supplier

At LJZ modern machine shop, we focus on providing aluminum precision machining service. Equipped with high-tech machines, including turning and milling machines, grinding, multi-axis such as 5-axis machining, 5-axis turning and milling etc. We are able to take the job of precision aluminum machining in a very quick turn.

As relyable China aluminum machining parts supplier, LJZ has passed ISO 9001, ISO16949, ISO13485 sertificates. This proves that LJZ has a perfect management system and manufacturing system to ensure quality aluminum machining and production. We are proud that we can fully compliant with the exacting requirements of our customers, strict compliance with PPAP and process FMEA for automotive customers and meet demanding requirements from medical customers!

China Aluminum Machining Surface Treatment

CNC aluminum parts are widely popular in almost every industry due to its excellent machinability. Another benefit of aluminum machined parts is that there are many options for its surface treatment, such as:

Anodizing

Powder spraying

Painting

Polishing

Sandblasting

Laser engraving

And many more

China Aluminum Machined Grade

Aluminium grades should be considered when choosing China aluminum machined technology. In recent years, due to its high strength-to-weight ratio, good corrosion resistance, good formability, and aesthetic appeal, aluminium die casting parts has increased its popularity. Since aluminum CNC parts are used in various industries, so selecting the most suitable China machining aluminum becomes more important.

As an expert aluminum machining supplier, we are familiar with the characteristics of each aluminum. Aluminium machining part supplier LJZ has always steeped ourselves in developing aluminum parts manufacturing. Below are some of the china aluminum machining part commonly used in our daily machining:

Features: Super hard aluminum alloy series, the main alloy elements are zinc, magnesium and copper. Deformed aluminum alloy plates with excellent heat treatment effect and ultra-high strength have good plasticity after solid melting treatment, and have good mechanical properties, wear resistance and fatigue resistance.

Application: mainly used in aerospace, auto parts, machinery, mold, etc.

Example: AL7075 is one of the strongest commercial alloys. It has strong corrosion resistance and is the best for aviation and marine plates. It's ideal for highly stressed parts. Mainly used in aerospace industry.

Machining 7075 aluminum and machining 6061 aluminum, Which One Should You Choose for Your Aluminum Parts Machining

The main differences between machining 7075 aluminum and machining 6061 aluminum are the following properties.

Aluminum series and chemical composition:machining 6061 aluminum has a higher silicon content, while machining 7075 aluminum has a higher zinc content. When looking at the exact range of data for both aluminum, it can also be seen that both aluminum contain a significant amount of magnesium, although machining 7075 aluminum has a slightly higher magnesium content.

Mechanical Properties: When looking at the two aluminum in the -T6 heat treatment condition, some significant differences can be seen. The first is that the tensile strength of 7075-T6 is almost twice that of 6061-T6. The second is that the shear strength of 7075-T6 is approximately 1.5 times that of 6061-T6.

Fabrication Considerations: The lower hardness and tensile strength make machining 6061 aluminum easier to manufacture than machining 7075 aluminum. machining 6061 aluminum is weldable, while machining 7075 aluminum is generally considered to be non-weldable.

Application Areas: Both aluminum are used for bicycle parts, aerospace parts and architectural structures. However, their specific uses in these areas differ.

Quality Assurance for CNC Aluminum Part

From the outside, different aluminum are indistinguishable by the naked eyes which greatly affects the quality of products. In order to ensure the authenticity of raw materials, LJZ is equipped with spectrometer which is able to strictly detect raw materials with testing report. Moreover, we also provide SGS material certificate according to customer's requirements.

Need Custom Aluminum Machining? Request a quote Now!

Aluminium Machining Service Processes

Swiss CNC Machining is a modern precision manufacturing process, which can produce very small parts quickly with tight tolerances and extreme accuracy. LJZ has 100+ state of the art Swiss turns and this helps us to produce million of swiss turned parts of in every month.

Precision CNC machining utilizes various tools and equipment such as CNC Swiss machines, 3,4,5 axis machines, horizontal and vertical milling, CNC turning technologies to remove raw materials to manufacture certain parts or assemblies. Which are suitable for machining complex aluminum parts with tight tolerances.

EDM uses the electric discharge generated between two electrodes to remove material from the workpiece. Although it can process any conductive materials such as aluminum and stainless steel. But because of cost, it's often used to machine harder and more difficult materials.

Custom Aluminum Parts Supplier Video

LJZ has conducted long-term in-depth and extensive theoretical research and practical verification, and has accumulated rich experience in the process of overcoming difficulties. Choose LJZ as your China aluminum machining supplier at bulk wholesale cost of machining aluminum

If you want to buy medical injection molding, contact us.

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント