CCS Motor variable frequency control of synchronous motor

(2024年04月10日)https://www.ccs-motors.com/ccs-motor-variable-frequency-control-of-synchronous-motor.html

In the ever-evolving landscape of electrical engineering, the control of synchronous motors has reached new heights with the advent of Variable Frequency Drive (VFD) systems. Particularly, the Variable Frequency Control of Synchronous Motors has emerged as a pivotal advancement, transforming the way we manipulate motor performance. In this article, we delve into the intricacies of this technology, exploring its applications, benefits, and the underlying principles that drive its success.

Frequency Control in True Synchronous Mode

At the heart of Variable Frequency Control lies the manipulation of the stator supply frequency through an independent oscillator. This process, often referred to as true synchronous mode, allows engineers to finely tune the frequency of the supply, steering the motor's behavior with unparalleled precision. By changing the frequency from its initial value to a desired one, the motor's speed, and consequently, its overall performance can be customized to meet specific requirements.

Speed Control of Synchronous Motor

Traditionally known as a constant-speed motor, the VFD for synchronous motor operates at the synchronous speed of the power supply. However, with the introduction of variable frequency control, this seemingly rigid characteristic is transformed. The ability to manipulate the stator frequency provides engineers with the means to exercise control over the motor's speed, a feat previously considered challenging in synchronous motor applications.

Relationship Between Speed and Frequency of Synchronous Motor

The correlation between the speed of a synchronous motor and the stator frequency is a fundamental aspect of variable frequency control. With a constant rotor excitation, the synchronous motor's speed is intricately tied to the stator frequency and the number of poles. By varying the frequency, engineers can effectively modulate the speed of the motor, offering a dynamic and flexible solution to various industrial applications.

Variable Frequency Synchronous Motor Drive

The performance capabilities of Variable Frequency Synchronous Motor Drives extend beyond simple speed adjustments. Engineers can fine-tune the drive's behavior by modifying both the frequency and engaging in field weakening techniques. This dual approach enables a higher degree of customization, empowering industries to optimize their operations for efficiency and precision.

Sensorless Field-Oriented Control

In the realm of Permanent Magnet Synchronous Motors (PMSM), sensorless field-oriented control takes center stage. Under no-load conditions, this advanced control technique adjusts the motor by manipulating the stator frequency, denoted as ωe. This sensorless approach enhances reliability and reduces costs associated with traditional sensor-based control systems.

Variable Frequency Drive

A Variable Frequency Drive serves as the backbone of these systems, functioning as an AC motor drive system that orchestrates speed and torque control by modulating the input frequency. This technology has become an indispensable tool in industrial settings, providing a seamless solution for achieving precise control over motor-driven processes.

The Variable Frequency Control of Synchronous Motors has ushered in a new era of precision and adaptability in the field of electrical engineering. By manipulating the stator supply frequency through independent oscillators, engineers can transcend the traditional limitations of VFD compatible motor, unlocking a realm of possibilities for customization and optimization. As industries continue to evolve, the Variable Frequency Drive system stands as a testament to the relentless pursuit of efficiency and control in the world of motor-driven applications.

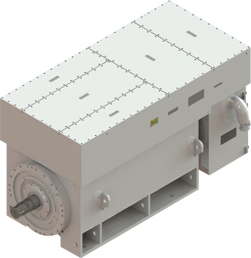

CCS Motor company is mainly oriented to coal mine, petrochemical, shipbuilding, metallurgy, electric power, large loading test bench and other fields. The electrical power transmission and control equipment have the characteristics of high protection, high efficiency, safety, environmental protection and energy saving. The electrical devices and control integrates motor, frequency conversion control, system control and data transmission, and can provide customized products and solutions according to customer needs.

- このできごとのURL:

コメント