5 REASONS OF MOLDY ALUMINUM DIE-CASTING MOLD

(2021年05月09日)https://www.empcasting.com/5-reasons-of-moldy-aluminum-die-casting-mold.html

Elements of the external environment. Aluminum is a vivid metal, and it is very easy to oxidize and turn black or mold under certain temperature and humidity conditions. This is the choice of aluminum itself.

There are internal elements of itself. Many manufacturers do not do any cleaning after the die-casting and machining processes or simply flush with water, which cannot be thoroughly cleaned. There are corrosive substances such as release agent, cutting fluid, saponification fluid, and other stains on the surface of die-cast aluminum. , These speed up the mold growth of aluminum alloy die castings;

Unreasonable process planning. Improper handling of aluminum alloy die-casting parts after cleaning or pressure inspection creates clear conditions for moldy aluminum alloy die-casting parts and accelerates the formation of mildew

The cleaning agent should not be used properly. Cleaning is highly corrosive, forming corrosion and oxidation of die-cast aluminum.

Storage handling is not in place. When the warehouse is stored at different heights, the mold will be different.

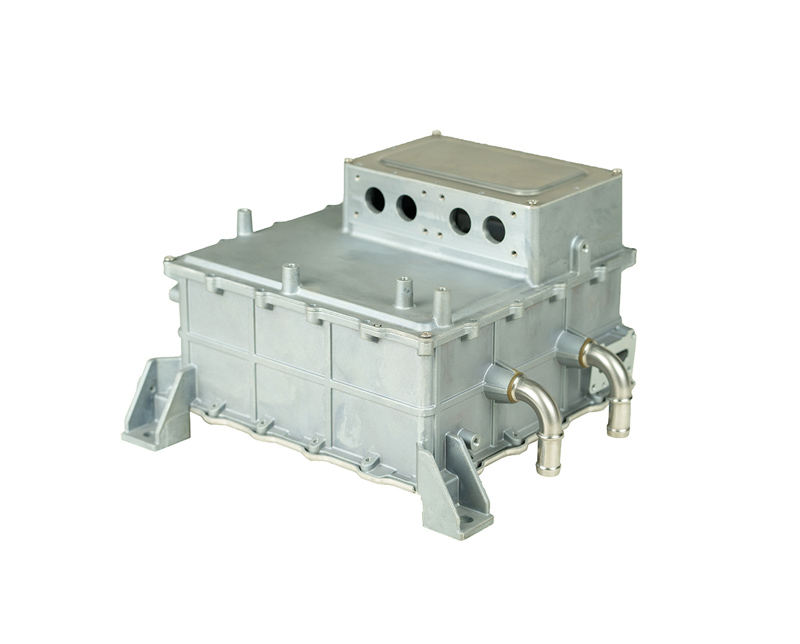

EMP Tech is one of professional die casting china companies. We provide Automotive Parts, Machinery Parts, custom automotive parts, die casting aluminum radiator, aluminum heat sink enclosure and so on. Want to know more? Please contact us.

- このできごとのURL:

コメント