Vacuum Moulding

(2023年05月04日)https://www.gmmoldtech.com/products/vacuum-moulding.html

In order to meet the requirements of small batch production and material performance, we provide vacuum injection molding for customers.

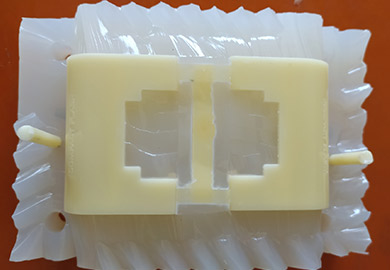

Vacuum Moulding Plastic to the use of the original template to make a silica gel mold in the vacuum state, and pour it with PU material in the vacuum state, so as to clone the same replica as the original template.

This is similar to the processing method of custom plastic injection mould. Products can use any material, such as ABS, PC, PBT, PA66 and so on. But its disadvantage is that the product precision is low and the die life is short!

Features of Vacuum Moulding

GM-TECH, a professional plastic mold technology inc, has designed and manufactured dozens of sets of automobile rear-view mirror molds for Kaiming hall in Murakami, Japan. The products are basically used in Toyota, Honda, and Nissan. In addition, we have also produced dozens of sets of lamp molds for Haila, including headlamp mask, headlight guide strip, headlight reflector, etc.

1. The production cost of vacuum moulding plastic is low. In the rapid prototype making industry, vacuum silica gel mold is often used for small batch reproduction production;

2. The service life of silica gel mold can reproduce and produce 10-20 same hand board products;

3. Fast speed, general working time: 1-4 hours / piece;

4. Standard copy accuracy of the replica hand plate: ± 0.10mm/100mm;

5. According to customer requirements, we can make vacuum moulding plastic products with exquisite appearance according to different colors;

6. It is suitable for trial production samples with complex product structure, uniform wall thickness and meeting certain functional requirements.

The Specification of Vacuum Moulding

Part namesample, prototype,

Part materialplastic

Machining accuracy+ / - 0.1

Tool life20 shots

Exporting countryIsrael

Delivery time1 week

Delivery modeDHL3 days

Mold quality customer satisfaction100%

Project cooperation service customer satisfaction100%

- このできごとのURL:

コメント