Overview of Cabinet Vibration Damping System

(2023年)https://www.hoanisolator.com/news/overview-of-cabinet-vibration-damping-system.html

It is well known that the mechanical forces received by electronic equipment come in many forms, among which vibration and impact are the most harmful, causing about 80 percent of faults. The main device resonates under the action of an excitation frequency, exceeding the limit of the equipment. Car-mounted electronic equipment is generally installed in the cabinet, mainly depending on the damping buffer of cabinet vibration damping system. The installation of the shock absorber has been standardized for the cabinet above 1.2 meters high. That is, four shock absorbers are installed at the bottom of the equipment and two shock absorbers are installed at the upper back.

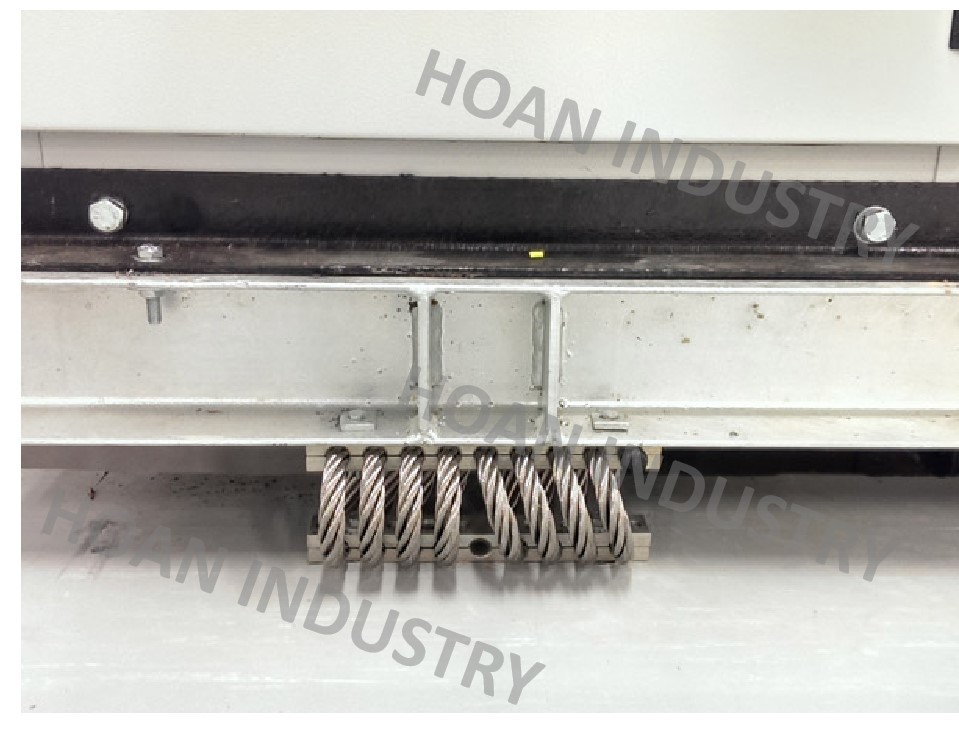

Anti-resonance design and decoupling design are two major problems to be solved in the vibration reduction system of the overhead cabinet. To prevent damage to equipment by excessive resonance transfer rate, in practice, we should first choose wire vibration absorber with low vibration transmission rate and low natural frequency to suppress the resonance of cabinet. The gravity installation is adopted for the cabinet shock absorber to avoid coupling vibration. In practice, however, this installation is difficult to achieve. In order to make the cabinet anti-vibration system have good anti-vibration effect, the vertical rigidity of the anti-vibration system is required to be close to zero, and its horizontal rigidity should match the horizontal rigidity of the bottom shock absorber.

Currently, there are four types of commonly used shock absorbers for automobile cabinets: type E shock absorber, wire rope vibration isolator, non-harmonic peak shock absorber and composite damping shock absorber.

The advantages and disadvantages are as follows:

type E shock absorber: The static deformation is small and the installation is convenient. It is more suitable for the internal installation of the square cabin and box, but the natural frequency is high (anti-resonance is required).

wire rope vibration isolator: The rigidity has a soft nonlinear characteristic, low transmission rate, and can adapt to various stress states. Wire rope vibration dampers are mainly suitable for wall-mounted installation.

non-resonant peak shock absorber: It has good vibration reduction and shock isolation effect, long life. But the load must be within 20% of the rated load of the shock absorber, otherwise, the effect will be worse.

composite damping shock absorber: It has good impact resistance. But it required installation space.

The angular acceleration of the cabinet of onboard electronic equipment is large, and the stiffness of the shock absorber at the bottom is weak for the horizontal direction.

The following principles should be followed when selecting the back shock absorber:

The vertical rigidity of the back frame damper should be approximately 0, so as to keep the vertical direction decoupling of the cabinet;

The horizontal rigidity should be symmetrical about the static equilibrium position of the cabinet to eliminate coupling resonance;

The vibration damper of the back frame should match the stiffness and damping characteristics of the bottom damper.

General measures to reduce vibration and buffer include:

Install the shock absorber. The damping and buffering of electronic products mainly depend on the installation of shock absorbers. At present, the standardized rubber shock absorber and metal spring shock absorber are applied in the electronics industry.

Enhance the vibration and impact resistance of products and components.

Buy wire rope vibration dampers.

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント