MACHINING MATERIALS IN PETROLEUM & CHEMICAL PROCESSING

(2023年04月23日)https://www.hqfactory.com/chemical-machining-application.html

Chemical Machining Process

The petroleum and electrical chemical machining industry placed great emphasis on the stability and durability of their equipment. HQ has provided parts and components for petroleum and chemical processing equipment manufacturers for years. By using our high-quality machining marine and casting parts, the maintenance time and downtime are saved for the equipment user. As a result, HQ has been the registered machining and casting parts supplier of several famous Japanese manufactures since 10 years ago. The secrete that how we pass their high-standard inspection and strict requirements is we always put ourselves in the customer's shoes. We participate in the project from the designing step by providing the best production solution to bring the drawing into the real products. We keep high transparency by timely reporting every progress of the production that providing the visibility of each step to the customer.

Our Products

We have produced various parts for the Petroleum and chemical processing industry including:

Flanges

Fasteners

Pump case

Vale parts

Flow-meter parts

Pipes

Special titanium material

Material And Fishing Support

We frequently work with common materials such as stainless steel, copper, brass, multiple grades of titanium, and aluminum. We also provide special material nickel base super-alloy, tungsten, molybdenum, tantalum, and even carbon fiber. In order to deal with the different extreme application environments, we also provide various surface treatments including polishing, sandblasting, PVD/CVD, galvanizing, anodizing, etc.

Popular Products

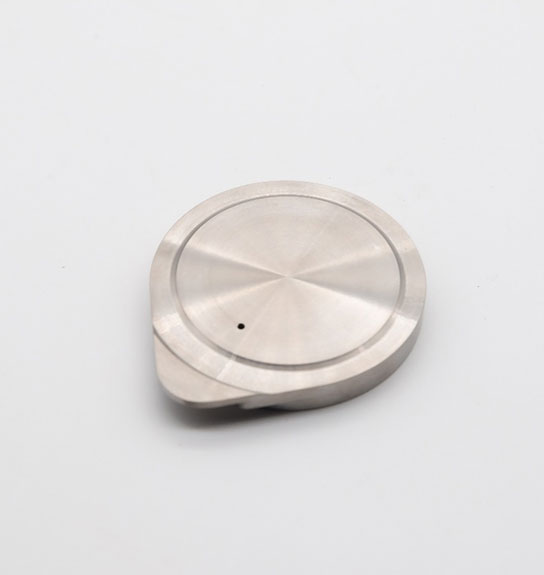

Titanium Washer Fluid Cap

Titanium Fusebox/Relay Cover

Titanium Socket Cap Bolt

More kinds of chemical machining application, please contact us.

Now the price of precision cnc services is reasonable, if you have needs, please leave us a message.

- このできごとのURL:

コメント