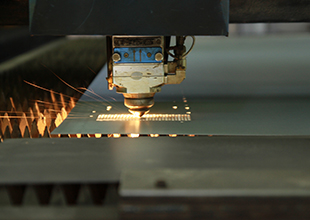

What Is Sheet Metal Fabrication?

(2021年)https://www.hsjfabrication.com/products/

As a professional stainless steel fabrication factory and sheet metal fabrication factory, Shenzhen HSJ Metal Fabrication Co., Ltd. has rich experience in providing professional sheet metal fabrication products to customers! With up-to-date technology and high-end sheet metal fabrication machines, we dedicated to provide high-quality custom sheet metal parts.

Sheet Metal Fabrication is a pivotal technology that sheet metal technicians need to grasp, and it is also an important process for forming sheet metal products. Sheet metal processing includes traditional cutting and blanking, punching, bending and forming methods and process parameters, as well as various cold stamping mold structures and process parameters, various equipment working principles and operation methods, and new stamping technology and new processes.

Selection of materials

The materials commonly used in sheet metal processing are cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet (SECC, SGCC), brass, red copper, beryllium copper, aluminum sheet (6061, 5052, 1010, 1060, 6063, duralumin, etc.), stainless steel (mirror, brushed surface, matte surface). According to the different functions of the product, the choice of materials is different. Generally, the use and cost of the product need to be considered.

1. Cold-rolled plate SPCC is mainly used for electroplating and baking parts. It has low cost, easy to form, and the material thickness is 3.2mm or less.

2. The material thickness of the hot-rolled sheet SHCC is greater than or equal to 3.0mm, and it is also used in electroplating and baking paint parts. The cost is low, but it is difficult to form, and it is mainly used as a flat piece.

3. There are galvanized sheets SECC, SGCC. SECC electrolytic plate is divided into N material and P material. N material is not used for surface treatment, and the cost is high. P material is used for spraying parts.

4. Copper is mainly made of conductive materials, and its surface treatment is nickel plating, chrome plating, or no treatment, and the cost is high.

5. Aluminum plate generally uses surface chromate (J11-A), oxidation (conductive oxidation, chemical oxidation). It is costly and has silver plating and nickel plating.

6. Aluminum profile is a material with complicated cross-section structure, which is widely used in various insertion boxes. Its surface treatment is the same as aluminum plate.

7. Stainless steel is mainly used for no surface treatment and has high cost.

- このできごとのURL:

コメント