Welding Hybrid Enclosures

(2023年12月01日)https://www.hsjfabrication.com/products/welding-hybrid-enclosures.html

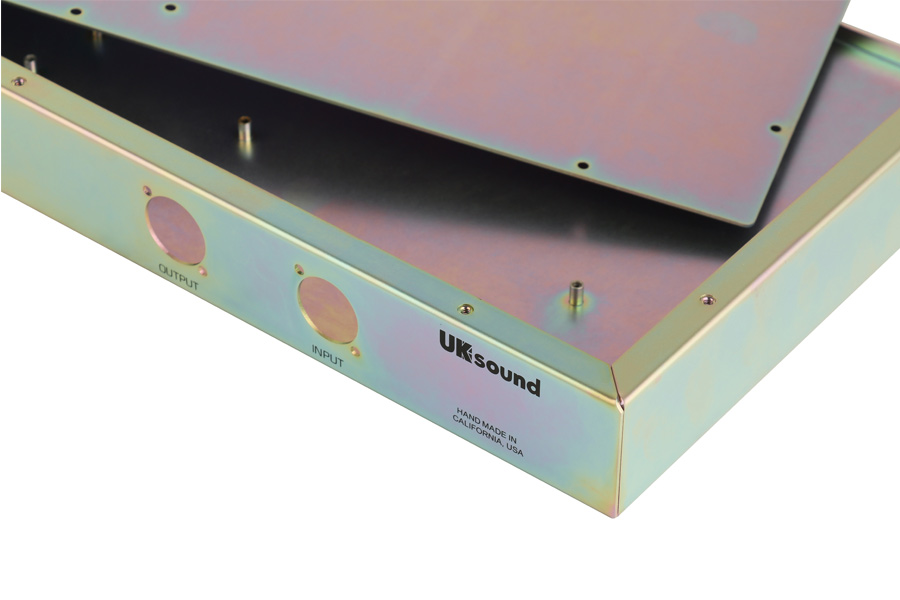

Welding Enclosure

Material:

spcc/steel/ sus/iron etc.

Tolerance:

0.1-0.2mm

Process:

Blanking - bending - pressure riveting - welding - polishing - electroplating environmental protection color zinc-packing

Surface treatment:

screen printing black logo and words. we provide other color and

Plating any color you just let us your sample or photo or Pantone color number.

The sheet metal has the characteristics of lightweight, high strength, conductive (can be used for electromagnetic shielding), low cost, good mass production performance and so on.

About the blanking: before cutting we need the operator to spray anti-rust oil on the surface of the steel plate, and spray oil to form a protective layer to prevent oxidation when discharging, and spray anti-rust oil. Gloves are required throughout processing.

Industry: Automotive, Electrical, Building, Furniture, Mechanical, Machine assembly, Computer, Air industry. OEM/ODM Electronics etc.

Packaging Details as bellow:

welding sheet metal box fabrication parts use Bubble bags, carton box, and pallet, wooden case to package.

Welding has two types of argon arc welding and laser welding.

What is argon arc welding?

Argon arc welding is a welding technology using argon gas as shielding gas. Also known as argon shielded welding. In other words, argon is applied around the arc welding to protect the air from oxidation.

The argon arc welding technology is based on the principle of ordinary arc welding, using argon gas to protect the metal welding material, and melting the welding material on the material to be welded into a liquid to form a molten pool by high current, so that the metal to be welded and the welding A welding technology that achieves metallurgical bonding. Since argon gas is continuously supplied in high-temperature fusion welding, the welding material cannot be in contact with oxygen in the air, thereby preventing oxidation of the welding material, so that stainless steel and iron those metal can be welded.

What is laser welding?

The welding process is heat conduction, that is, the laser radiation heating workpiece surface, surface heat through the heat conduction to internal diffusion, through the control of laser pulse width, energy, peak power, and repeat frequency and other parameters, the workpiece melting, forming a specific pool. Due to its unique advantages, it has been successfully applied in the precision welding metal parts.

We provide the welding enclosure for you.

There are many sheet metal components manufacturers in China, but we are one of the best choices for you.

If you want to find a reliable sheet metal shop china, please choose us, and we will be your best partner.

- このできごとのURL:

コメント