Custom PCB Project

(2023年03月05日)https://www.hx-technology.com/custom-pcb-project/

DRC Check-in Design Custom PCB

In the manufacturing industry, does the process designer need to check the design results after design custom PCBboard? The answer is yes.

DRC check, also known as design rule check, which is PCB design software (EDA) used in the PCB Layout process in real time to check and find the design does not match the intended design specifications. DRC check is used to ensure the correctness of the design and meet the conventional design specifications as a starting point, is an indispensable part of the custom PCBboard design. Based on the role and purpose of the DRC, it is generally no more than 100 check line items.

Meet the DRC check is the most basic requirements of design custom PCB, to meet the DRC does not necessarily mean to meet the manufacturability requirements.

DFM Check-in Design Custom PCB

DFM check, also called design for manufacturability analysis, is based on custom PCB data through real 3D component models and actual manufacturing process simulation, a comprehensive design review of PCB and PCBA manufacturability before fabrication. The first time to find the design custom PCB defects or deficiencies, process difficulties, manufacturing risks, design custom PCB and process mismatch factors, etc., to ensure that the custom PCB design and process capabilities fully match. As a PCBA company, HX Technology will essentially reduce the number of trial production, save production costs, and improve product reliability.

DFM is a bridge between design custom PCBassembly and manufacturing process, which belongs to the category of process design, through which you can find the mismatch between design and manufacturing process factors, assess the manufacturing difficulty, manufacturing risk, etc. These are not covered by DRC in order custom circuit board design software.

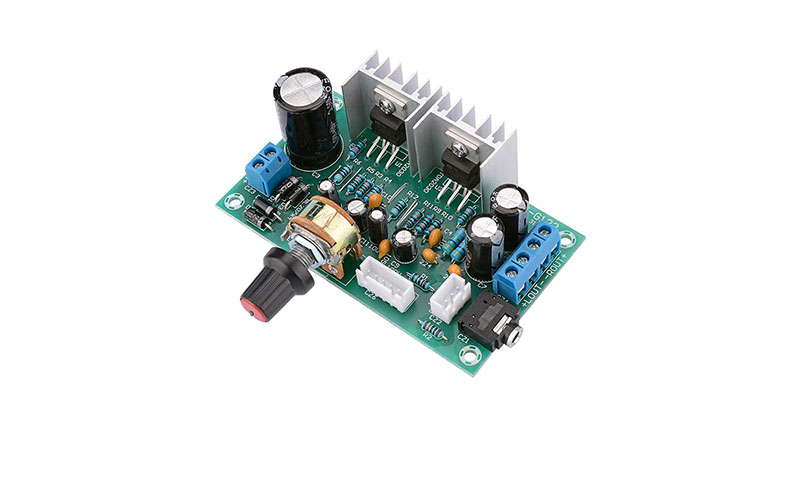

Power PCBA Board

Custom circuit board design need to find professional suppliers, and users need to make reasonable judgments in the process of selection. Choose a professional supplier can ensure the actual production advantages, can be quickly put into use, to obtain better conditions of use. hx technology can ensure the value of the product, to understand the better quality suppliers in order to work closely together.

Control PCBA Board

The production of PCBA processes requires a refined mode of operation and a greater understanding of the degree of specialization in the selection of suppliers. HX Technology has created a unique production line, and the actual scale of production is expanding, strengthening the advantages of production. We are able to produce better products in a shorter period of time.

Instrument PCBA Board

HX Technology, as a professional manufacturing service provider, relies on the layout of a flexible production network to help you complete the entire manufacturing and supply chain service from product prototype to mass production. With multiple production lines as the support to build a flexible production network, you can achieve high efficiency and fast response no matter what stage of your product.

As a PCBassembly supplier, we will do our best to meet all the needs of clients.

- このできごとのURL:

コメント