Leading Case

(2023年02月26日)https://www.jewardmould.com/leading-case-of-plastic-injection-molding/

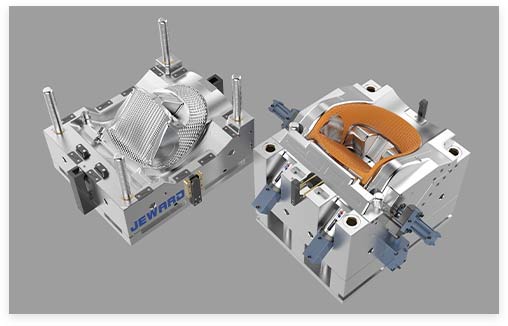

LEADING CASES OF PLASTIC INJECTION MOLDING

New injection technologies are important impetus for the development of injection molding industry. For example, the in-mold labeling could largely improve the container's outlook and quality, also, gas assist molding helps reducing product's weight and enhance the strength. Now, more and more plastic injection moulding supplies manufacturers are embracing these new technologies and we, Jeward Mould, has always been at the forefront of trend. We have confidence to provide our customers best plastic injection moulding services for different plastic injection molding demands and processes.

DIFFERENT TYPES OF INJECTION MOULDING TECHNOLOGY

In Mold Labeling

A practical molding process for decorating, help you getting rid of labeling machine.

Insert Molding

Inserting metal components into mould to stably combine the plastic product and component, also able to produce two color product.

Stack Molding

Stacking multiple mold parting surfaces together, doubling the productivity of injection machine without extra cost.

Gas Assist Molding

Injecting plastic and gas into an injection mould under low-pressure to form hollow parts.

Thin Wall Molding

Thin wall molding allows products having lighter weight and stronger structure, it's popular in food packaging area.

Multi Shot Molding

Molding a part with two different colors or materials, improve the part's appearance and function.

Large Part Injection Molding

Pallet, Wheeled Garbage Bin, Agriculture Crate & Bin…..more and more logistic product made by injection mould. We Jeward is good at making mould for large part, apply to plastic injection machine up to 4000 tons.

There are many plastic mould suppliers, but we are one of the best choices for you.

- このできごとのURL:

コメント