THIN WALL MOLDING

(2023年)THIN WALL MOLDINGhttps://www.jewardmould.com/thin-wall-molding/

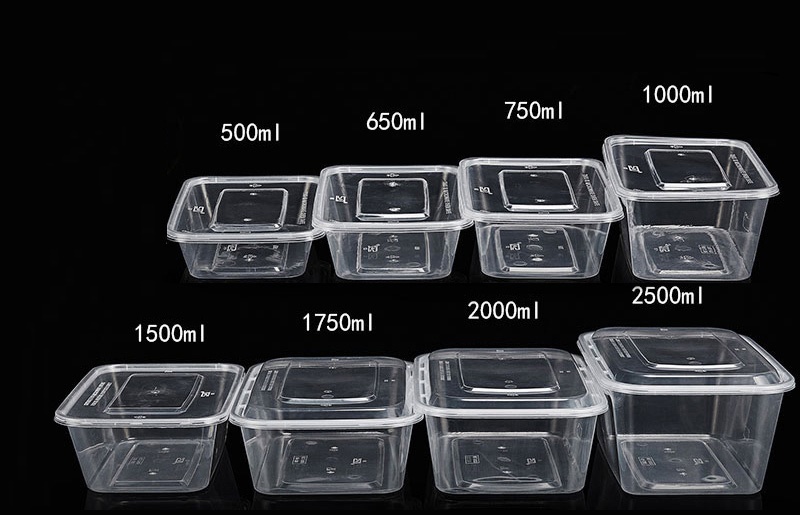

Thin wall mould is process for products having wall thickness less than 1MM. It has been more and more popular in food packaging, medical, stationery and many other areas. Since consumers are paying more attention to food safety issue, the thin wall food container of PP is widely used in food packaging industry.

Compared to normal injection molding, thin wall molding has following advantages:

Thin wall and light product

Short cycle time, high productivity

Perfectly match with robotic to achieve automatic production, realize mass production in short term

Good surface finish

Huangyan mold’s design team is familiar with thin wall molding. With the mold flow analysis program, we could put forward reasonable product drawing and mould structure design. Our suppliers could offer high-quality mould material and parts, which are suitable for thin wall container mould design. To satisfier the process of thin wall mould, we have several processing machines with high precision.

CASE STUDY

THIN WALL MOLDING – 1000ML THIN WALL BOX

CHALLENGES

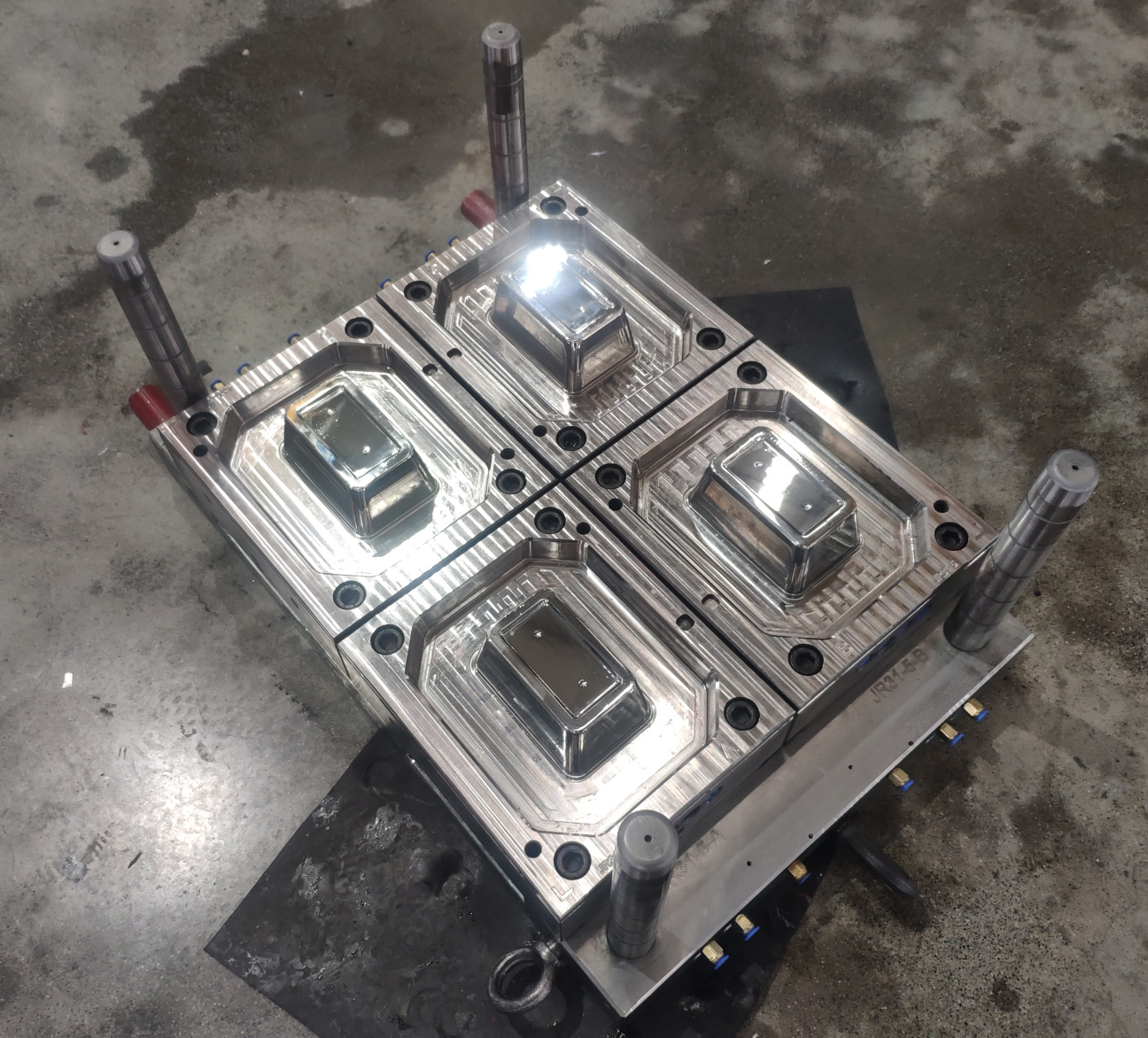

Thin wall molding techniques have high requirement for mould design and manufacture. Since the cycle time is short, the mould’s cooling system needs to be highly reliable. The thinness of wall demands very low machining error. Even 0.02mm deviation could influence the forming. Also, the pressure and speed is high during the thin wall injection molding process. The mould needs to take high pressure, therefore, the high quality material is necessary.

ENGINEERING & TECHNOLOGY

The design of wall thickness needs referring to mold flow analysis result, to ensure the good flow environment for material.

We will consider the mould cooling requirement during production, design an efficient and reliable cooling system for mould. Also consider the mould maintenance, we used independent core and cavity.

With high precision processing equipment, we can achieve low machining error.

SOLUTION & RESULTS

The high-quality steel, our reasonable design and high-precision machine function together perfectly to manufacture moulds adoptable for thin wall molding. Now, we have delivered multiple batches of multicavities thin wall moulds in 500ML-3000ML. With the help of robotic, our thin thin wall food container mould could product automatively in 5 second cycle. It makes the production more effective and creates higher profits for our customers.

Typical case: 1000ml Thinwall box mould:

Product Dimension: 170×115×72mm

Product Thickness: 0.38mm

Product Weight: 17.5g

Cycle Time: 6S

Mould Dimension: 1190×750×690mm

Mould Weight: 1580KG

FAQS ABOUT THIN WALL MOLDING

Q

What's the thin wall molding?

-

A

The ratio of distance from the injection point to the end of melt flow and average wall thickness is 100 or more than 150, this kind of injection molding is Thin wall molding.

Q

What kind of steel is suitable for thin wall mould?

+

Q

Dose the thin wall molding need to go with chilling machine?

As a plastic mould maker, we will do our best to meet all the needs of customers.

- このできごとのURL:

コメント