Inspection for Cold Roll Forming Machine Before Startup and Its Differences from Cold Bending Machine

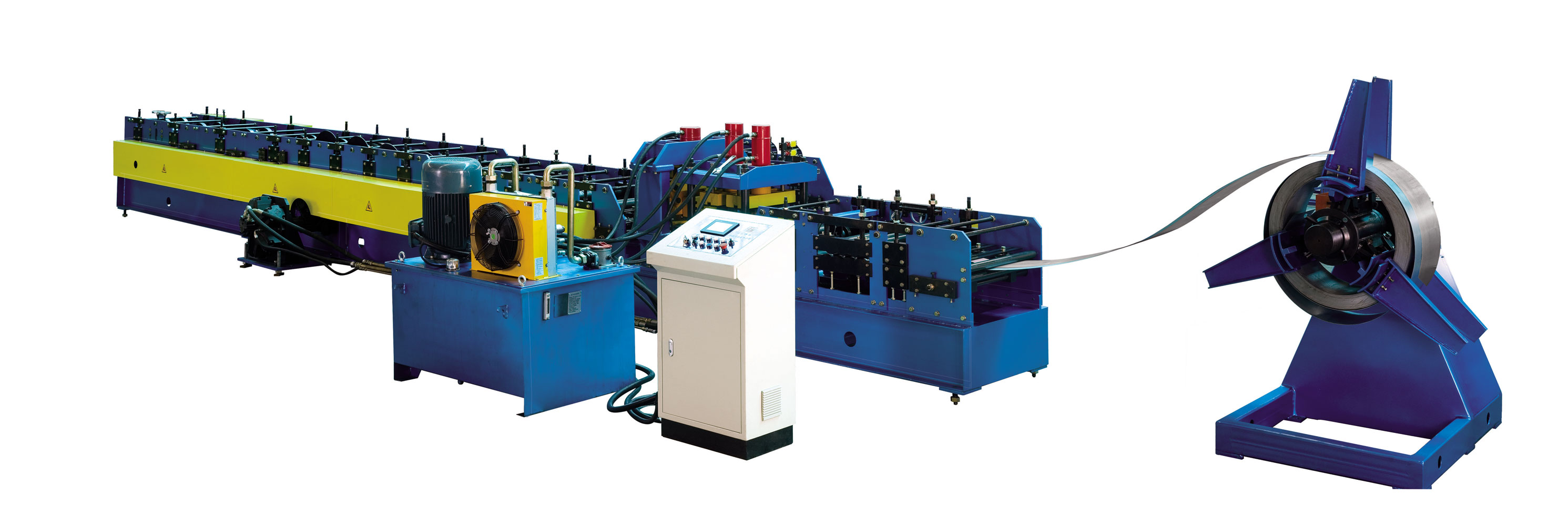

(2021年06月24日)Is the cold roll forming machine strange to us? And is it the same as the cold bending machine? The above questions are related to the cold roll forming machine, so we must understand and master them, otherwise, we can't learn this product well. Since they are so important, we will answer the questions in the content below, hoping that you can get some help and inspiration from them, so as to benefit from them.

1. The inspection before starting the cold roll forming machine mainly includes the following points:

(1) Check the joints to see whether they are firm or loose, whether the rotating parts are flexible, and whether they are jammed.

(2) Whether the lubricating parts of the equipment are well lubricated, whether the oil quantity is sufficient, and whether the lubricating oil in each transmission gearbox is above the oil gauge line.

(3) After passing the above inspection, start the slipping motor for no-load trial operation, mainly to check whether there is any abnormality. After the end of idling, check whether the temperature rise of every rotating part is normal, whether there is oil leakage, and whether the fasteners are tight. If there is any problem, it should be solved in time.

2. Differences between cold roll forming machine and cold bending machine:

Cold roll forming machine and cold bending machine, although literally similar, but the two are still different, can not be confused. The cold bending machine is mainly used to process the tunnel supporting steel arch frame, while the cold roll forming machine can be directly used in the assembly line, so the processing degree of them is different. Moreover, their emphasizes are different.

Zhejiang Jinggong Science & Technology Co., Ltd is a professional roll forming machine factory. We provide Sandwich Panel Machine, Roll Forming Machine, building materials machinery and so on. Want to know more? Please contact us.

- このできごとのURL:

コメント