Paper Industry Wastewater

(2024年)https://www.jiuwumembrane.com/application/paper-industry-wastewater.html

Standard discharge, reclaimed water reuse and zero effluent discharge

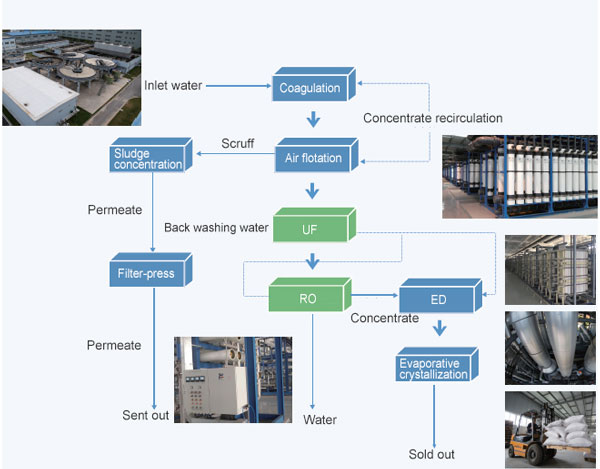

1. As for paper mill wastewater treatment, pulping wastewater is the most difficult wastewater to be treated in the papermaking industry. The organic pollutants and inorganic salts are high in content, complex in composition, high in hardness, high in costs. The technical staff of JIUWU work with experts from the Institute of Membrane Science and Technology of Nanjing Tech University and develop successfully membrane technology as the core of zero effluent discharge process or zld (zero liquid discharge).

2. Using the paper mill wastewater treatment process, membrane integration, evaporation crystallization and other related processes turns waste into valuable and achieves the sewage recycle. The project forms a major technological breakthrough in the field of pulp and paper mill wastewater treatment.

Application background

Industrial water prices continue to rise

Industrial water intake limit

Increased emission water quality standards (COD, TOC, etc)

Enforcement requirements for environmental protection and water reuse rate, etc.

Large demand for fresh water

Large amount of wastewater discharge

The composition of wastewater is complex, and the content of organic pollutants and inorganic salts is high.

Core advantage of process package

Independent research and development, Global First

Turn waste into treasure and realize 100% full reuse of wastewater

Multiple 10,000-ton demonstration projects

Reuse water, salt, and dry mud

The water quality of the produced water is good and meets the requirements for productive reuse.

zld (zero liquid discharge)

Case

Jiangsu Jiuwu Hitech Co., Ltd has done the largest zero liquid discharge project in paper pulp industry. The project is located in Japanese Oji Paper Co., Ltd. (OJI PAPER) in China, the scale of 40000m3/day of papermaking, pulp wastewater. Main processes include ozone-coupled biofilter (removing COD), the integrated membrane system of uf technology and reverse osmosis, electrodialysis (EDR) concentration system, MVR evaporation crystallization system. Through above-mentioned advanced processing system, the realization of wastewater recycling and zero liquid discharge. The clean water is supplied to the power plant desalination system and the production water system, waste salt is supplied to the Transportation Bureau to do snowmelt agent and chemical raw materials. The project which is the world's largest zero liquid discharge project in paper pulp industry has been stably operating for more than 3 years.

If you want to know more about paper mill effluent composition, please visit our website.

As a ceramic membrane factory, we will do our best to meet all the needs of customers.

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント