Sweetener

(2024年)https://www.jiuwumembrane.com/application/sweetener.html

A sweetener is a food additive that provides a sweet taste like that of sugar while containing significantly less food energy. Some sugar substitutes are produced by nature, and others produced synthetically. Those that are not produced by nature are, in general, called artificial sweeteners.

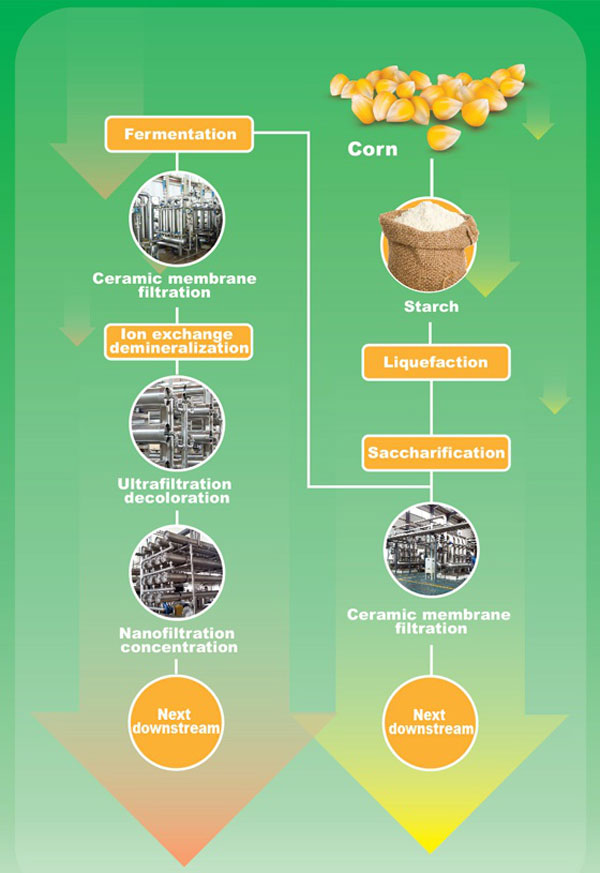

Ceramic membrane technology is finding application in the sweetener industry for clarifying, concentrating, and purifying these important products. They are also ideal for treatment of waste streams from sweetener processes, either for recovery and reuse or treatment prior to waste disposal.

Removal of haze and color from sugar syrup, the concentration of sugar water, can both be accomplished via ceramic membrane filtration processes.

GLUCOSE SYRUP

Glucose syrup, also known as confectioners glucose, is a syrup made from the hydrolysis of starch.

In the food industry, glucose can be produced by iso-enzyme treatment of fructose, especially fructose syrup containing fructose 42% which has similar sweetness to sucrose and become an important product of the current sugar industry.

Glucose is produced by enzymatic hydrolysis of starch milk under certain conditions In the preparation of glucose, there will be a part of protein, fat, fiber, pigment, salt, and other impurities, directly affect the quality of glucose. The application of integrated membrane separation technology containing ceramic membrane & organic membrane filtration has become a new energy-saving cleaner production technology.

Advantages :

Filtrate clear;

excellent transparency,light transmittance > 97%;

reduce the amount of filter aid;

save production costs;

Cane & Beet sugar

Membrane technology can be used in the production of sugar cane juice drinks, original brown sugar; "Membrane - resin process package" can be used for production of refined sugar, high-quality sugar, primary sugar, raw sugar and edible syrup which replaces the traditional one-step, two-step method in the process of liming, sedimentation, plate-frame.

"Membrane resin process package" has unique advantages of clarified sugar cane juice, without muddy, without adding chemical reagents, effective interception of microorganisms, reduce energy consumption, short process, small footprint, achieving CIP cleaning, good regeneration performance, long service life.

Continuous ion exchange technology is a completely innovative separation technology, which is based on the traditionally fixed bed resin adsorption and ion exchange technology, combined with the continuous countercurrent system developed. Through continuous ion exchange, can make separation column in a process cycle to complete the adsorption, washing, regeneration, eluting.

The advantages of continuous ion exchange technology

① compact structure, less piping, small footprint

② high resin utilization, can reduce the amount of 50% -70%

③ high product yield, concentration and purity, and stable

④ washing and chemical reagents consumption less, save 50% -70%

⑤ little waste emissions, greener

Membrane - resin process package" advantages

① can effectively filter clarified cane juice, the product is not muddy.

② without adding chemical reagents, reduce solid waste emissions.

③ high production efficiency, reduce labor costs, improve product quality, improve sugar yield.

④ high precision membrane filtration, which can effectively intercept microorganisms.

⑤ reduce follow-up evaporation energy consumption by 50% and production costs.

⑥ short process, compact, small footprint, reduce capital costs.

⑦ membrane and resin can achieve CIP cleaning, good regeneration performance, long service life.

If you want to know more details of sugar filtration, please visit our website.

We can provide high quality ceramic membrane filters for sale, if you have needs, please contact us.

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント