INJECTION MOLDING SERVICES

(2021年)https://www.lcrapid.com/injection-molding/

We are a leading top injection molding companies of high-quality customized metal and plastic parts. We have been providing high precision rapid prototyping services,custom machining services,on demand 3d printing service,vacuum casting services,sheet metal fabrication service and so on.

Rapid Prototyping

Manufacturing

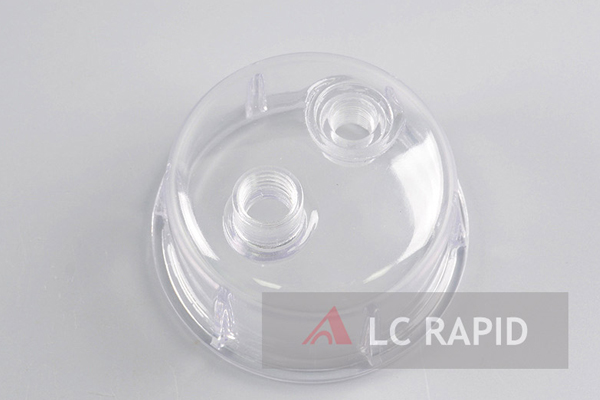

LC Rapid is an expert of best injection molding companies in advanced technology when it comes to plastic injection mold manufacturing. With advanced technology, high quality plastic material, good quality control process, decades of manufacturing experience and a team of experienced project managers, we can ensure exceptional quality tools and parts that exceed your expectations being delivered on time. We can produce 25 to 100,000+ parts. We embrace advanced technology and cost reduction measure to guarantee our competitiveness in the global market. Just upload your product design and request information to complete your project.

Injection Mold Manufacturing Services

Plastic injection mold machining is a manufacturing process that requires an injection molding machine, raw plastic resin, injection mold tools.

The precision plastic injection molding process consists of the following key steps.

Step 1: The plastic resin begins as raw plastic pellets. These have been treated by drying, and then if necessary dyeing with pigments or master batch colorants.

Step 2: The pallets are fed into the machine through a funnel-shaped hopper. A reciprocating screw inside the barrel of the machine will inject these resins into the mold’s runner system.

Step 3: Resin pallets are loaded into a heated and compressed chamber called the barrel where they will be melted, forming the liquid resin.

Step 4: The melted resin enters into the mold cavity through a nozzle under high pressure.

Step 5: After the mold’s cooling and solidification, the part has been demoulded to the shape of the mold cavity.

Step 6: The mold halves (cavity or “A” side and core or “B” side) open up and a cycle begins again for the next part.

Injection Molding Process

Insert Molding

Insert molding is a great injection molding process that combine metal and plastics into one single part. It allows inserts such as helicoils, screws, metal filters to go inside your mold.

Overmolding

The overmolding is a multi-material injection molding process that allows clients to get the final item that involves two or more different types of material.

Mold Making

We offer design and manufacturing services for mold, dies, and tools to produce high quality plastic parts. Clients owe the tools.

Thermoplastic Injection Molding

LC Rapid produce custom injection molded items from hard toolings for low volume plastic molding and large runs of production.

Precision Plastic Injection Molding Tolerance

The tolerance depends on the injection plastic, tooling structure, and the design geometry, injection molding part tolerance need to be discussed every project, we will attempt to meet your tolerance standard.

Precision Plastic Injection Molding Finishes

Surface FinishGuideTypical Applications

SPI A-1Grade #3 diamond buffHigh polish parts, optically clear.

SPI A-2Grade #6 diamond buffHigh polish parts.

SPI A-3Grade #15 diamond buffHigh polish parts.

SPI B-1600 Grit Paper.Medium polish parts.

SPI B-2400 Grit Paper.Medium polish parts.

SPI B-3320 Grit PaperMedium- Low polish parts.

SPI C-1600 Stone.Low polish parts.

SPI C-2400 Stone.Low polish parts.

SPI C-3320 Stone.Low polish parts.

SPI D-1Dry Blast Glass BeadSatin Finish.

SPI D-2Dry Blast #240 Aluminum OxideDull Finish.

SPI D-3Dry Blast #24 Aluminum OxideDull Finish.

Standard No Machine MarkRemove tooling marksLow Cosmetic

Mold TexturingWe can match a wide varieties of mold textures upon request.

- このできごとのURL:

コメント