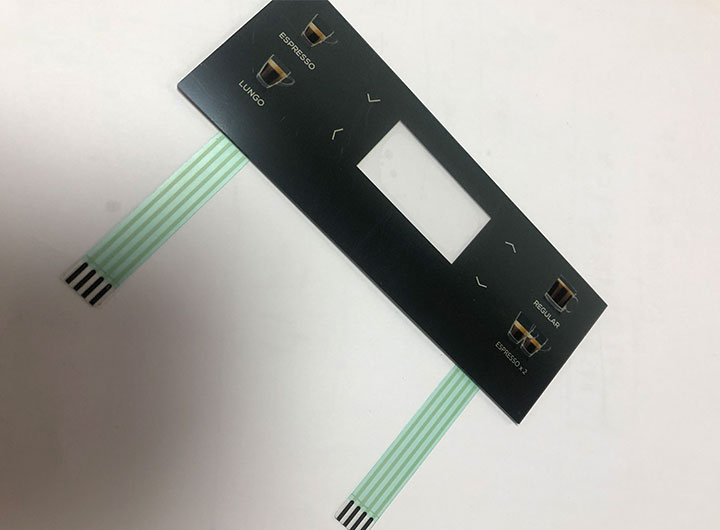

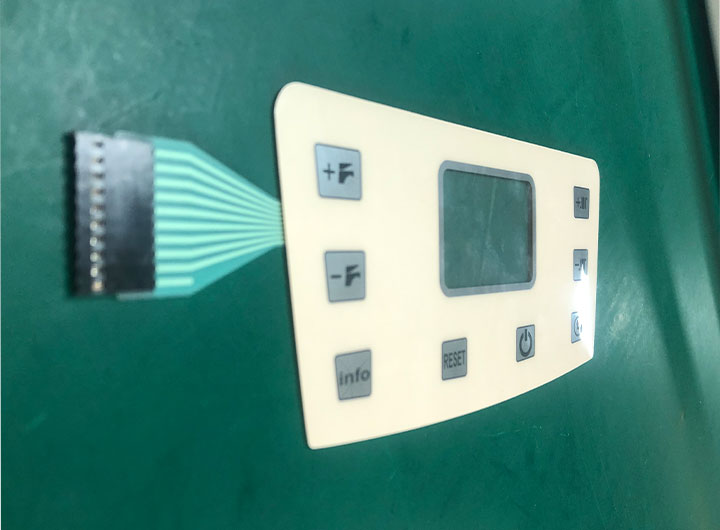

Silver Flex Membrane Switches

(2021年)https://www.niceone-tech.com/products/silver-flex-membrane-switches.html

The most common structure in custom Flex membrane switches is Silver Flex Membrane Switches. The conductive ink, carbon oil, and UV ink are printed on Polyester by screen printing, and the other layers are separated by adhesive. The LED can also be installed in the lower line to form a simple membrane switch with the shrapnel. The simplest structure is a single button membrane switch. The product is very thin, the cost is more affordable and easy to customize. Niceone-tech believes that the metal dome switch has a more obvious feel than the touch screen, and the membrane switch has better auditory, visual, and physiological effects for the touch screen.

What Are the Silver Flex Membrane Switch Design Options?

Digital and/or screen printed on the backside. The effect can be customized according to your requirements including glass, metal, wood, and stone. If the panel is in a more severe environment, we can even use hardened glass and stainless steel as the panel material. It is very important to choose Overlay printing according to requirements.

The window needs raw materials to be transparent, frosted, transparent or colored. The window of the membrane switch is different, and the choice of materials is also very different. When the window is large, and it is required to clearly see the bottom LCD or touch screen. EBG series is a good choice, the material is scratch resistant. If it is just a panel, then PC or Lexan overlay is also feasible

Top Circuit Layer (Dome retainer): This layer usually has three functions: 1. As the Dome Retainer, it ensures that the Snap dome of the circuit layer will not form shrapnel movement due to triggering and closing, resulting in circuit failure and circuit wear. 2. Use 0.1-0.125mm Polyester printing conductive ink, carbon oil, and UV ink as the upper line. This layer structure can also be convex to make tactile feedback better. 3. Can be used as an ESD shielding layer.

Circuit Spacer (switch spacer): Both upper and lower lines are printed with conductive ink, usually thicker tape is used to separate the upper and lower lines to avoid direct conduction of the membrane switch. If the upper circuit is only used as a fixed layer, then the general thickness of the Overlay adhesive + Top Circuit Layer + Lower Circuit Layer should be greater than 0.4mm, otherwise, the panel will squeeze the shrapnel to make them feel worse. Unless the panel is convex, the four-layer structure is less than 0.4mm.

Lower Circuit Layer: The thickness of this layer circuit is usually 0.1-0.188mm. It can be printed with ink, carbon oil, and UV ink. LEDs can also be installed. Some membrane switch panels will choose the copper flex or Printing circuit Board as the circuit. Compared with Polyester, their performance will be more stable. More often applied to the medical and military industries. If it is copper flex or Printing circuit Board as a line, Niceone-tech can even install a variety of components on the line.

Rear Adhesive: There are many choices, but the most commonly used are 3M200MP series or 3M300LSE. According to the different products of membrane switch lamination, Niceone-tech will recommend 3M300LSE if it needs higher viscosity.

Rigid Support Layer: This layer structure is generally used as the last layer of the membrane switch, which can make the structure of the membrane switch component more complete. Usually, the choice of materials is AL, FR4, PC, or steel. If AL is selected, nuts or feet may sometimes be added to the back of the product.

Niceone-tech is a professional membrane keypad manufacturer, we provide human machine interface control module, silicone rubber keypad, silicone rubber keyboard, rubber membrane switch, membrane touch switch and etc. Want to know more? Please contact us.

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント