Aluminium Surface Finishing

(2022年02月18日)https://www.otalum.com/aluminum-surface-finishing/

OTALUM was founded in 1984 and after 36 years' development, we have now already become a professional aluminium profile company for architectural systems and industrial applications. Our total annual output can reach 15000 tons, and we produce a wide range of products, including window and door systems, curtain wall, performance louvre, heat sinks, solar panel framings. Customized service is available. Our engineers can help you design your extrusion structure and produce your own system.

Aluminum Surface Finishing

For certain applications, aluminum extrusions require no more protection than its oxide film. If additional surface protection is desired, Otalum can assist. Our knowledge of alloys, properties and end-use enables us to help you match the aluminum surface finish chart to your project.

There is a variety of surface finish you can apply to your extruded profiles depending on the end-use of extrusions. Some of these surface treatments improve color, hardness, surface appearance and wear resistance.

Following are the most common-used surface finishes of aluminium extrusions in Otalum.

Aluminum Anodizing

Anodizing aluminium is an electro-chemical process that provides a stronger, corrosion resistant surface and preserves a “brand-new” appearance.

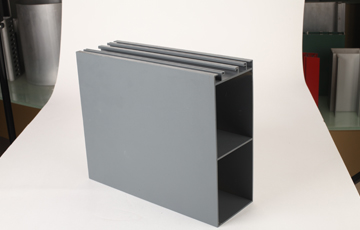

Aluminum Powder Coating

Powder coating is a surface treatment process used to give the surface corrosion resistance while providing a decorative appearance.

Aluminum PVDF Coating

A resin-based coating provides protection against weathering, ageing and pollution.

Aluminum Wood Grain Finish

Wood grain finish starts with powder coating and laminates a wood film in the surface of aluminium extrusion to provide a wood-look appearance.

- このできごとのURL:

コメント