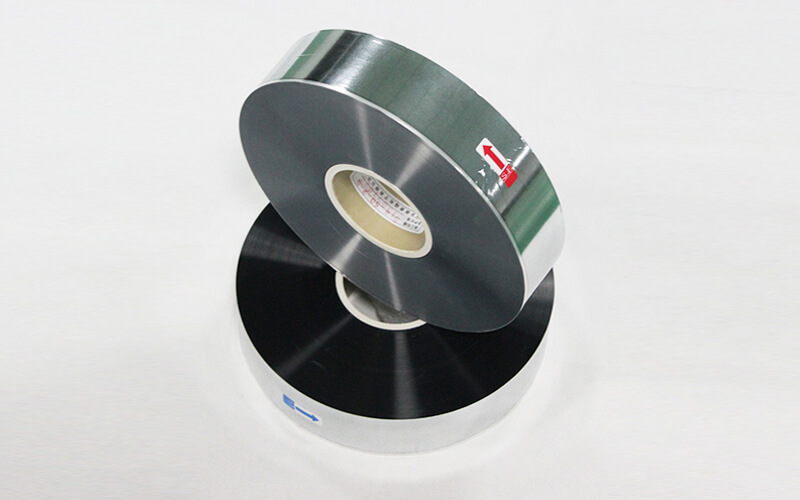

Polypropylene Metallised Film

(2024年03月15日)https://www.anhuisaifu.com/products/metallised-polypropylene-film-mpp-film/

Metallized polypropylene film for electrical appliances can be coated with a very thin plastic film on its surface.

Metallised polypropylene film will melt under high vacuum melting and the evaporation of the upper. Metalized polypropylene film is the main raw material for thin film batteries.

Types of Polypropylene Metallised Film

Single Margin Zinc Aluminium MPP Film With Heavy Edgy

Single Margin Zn-Al MPP Film With Ramp Resistance

Single Margin Zn-Al MPP Film With High Resistance

Segmented MPP Film With Diamond Pattern, T Pattern, 1/2 Pattern

Al or Zn/Al MPP Film Multiple Series Margin

Wave Slitting Zinc MPP Film

Al MPP Film Both Side Margin

Al MPP Film With Center Margin

Features of Metallised Polypropylene Film

Base Film

Biaxially Oriented Polypropylene film (BOPP film).

Melt, Evaporate And Precipitate Material

Melt, evaporate and precipitate high-purity aluminum or zinc on BOPP base film under a high vacuum, and form a very thin metal layer on the surface of BOPP base film.

Self-healing Effect

It has a self-healing effect. After the local breakdown of metallized film medium, it instinctively recovers to the electrical performance phenomenon before breakdown.

Margin

Margin refers to the requirement of actual capacitor production. The blank insulating strip (strip) formed by covering the edges or middle of one or both sides of the metallized film without metal evaporation is called the margin, and its width is called the margin.

The Square Resistance

The resistance value of the metal layer on the metallized film of square resistance in the unit square area is called the square resistance, which is expressed in Ω/□. Generally, the square resistance is used to represent the thickness of the metal coating.

Thickness and Width

Thickness: 2um - 12um

Width: according to the customer's design needs, the steam plating and slitting shall be carried out.

Storage of Metallised Polypropylene Film

Prior to use, the metallic film should be kept in its original packaging at a temperature between 5 and 35 °C and a relative humidity of no more than 85%.

When exposed to moisture, metalized layers are readily oxidized.

As a result, once opened, the film should be utilized as soon as feasible.

After opening, a temperature between 15 and 25 °C with a relative humidity of under 60 % is advised.

The storage time can be as follows when the original sealed container is kept as described above:

Aluminized film: 12 months after the date of delivery.

Metalized Al/Zn alloy film:

The storage time (as measured from the delivery date) depends on the film's resistivity because zinc is rather unstable:

≦10Ω: 6 months

10-30Ω: 3 months

>30Ω: 1 month

What is Metallised Polypropylene Film Used for?

Metallised polypropylene film is used in film capacitors, such as MKP/MFP (CBB) capacitors, EMI suppression capacitors, AC motor capacitors, Power electronic capacitors (DC-Link capacitors, DC filter capacitors, AC filter capacitors), DC pulse capacitors, DC high voltage Storage capacitors, Self-healing shunt power capacitors (Power factor correction capacitors), etc.

As a capacitor factory, we can provide types of industrial capacitors for sale, anything you need, please leave us a message.

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント