THE PERFORMANCE OF THE MUD PUMP

(2020年07月27日)https://www.saigaogroup.com/product/mud-pump-crosshead.html

As an essential component of drilling equipment, the mud pump refers to the flushing machinery whose duty is to feed the hole with washing fluid like mud and water in the course of drilling.

In the direct circulation of the general drilling, the mud pump forces the surface flushing medium (water, slurry or polymer fluid) all the way through the high-pressure hose and the faucet into the center hole of the drill stem then down reaching the bottom of the well to cool the drill and rush the leftovers to the surface.

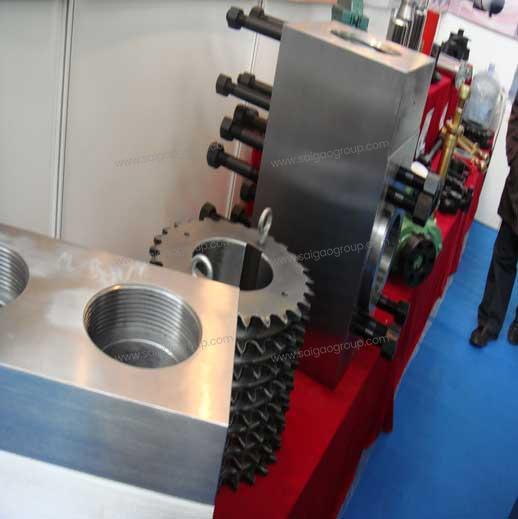

The commonly used mud pump is a piston one or a plunger one with a crankshaft driven by the power machine. The piston or plunger led by the mud pump crosshead runs reciprocally in the pump cylinder. The target of pressure delivery and flushing circulation are achieved by the crosshead under the alternating action of the suction and discharge valves.

Performance: Two major parameters of the mud pump performance are the discharge and the pressure.

Discharge: Calculated by the number of liters per minute, it is related to the diameter of the hole and the speed of the return flow. The larger the hole, the greater the discharge. The back velocity of the flushing fluid is at least fast enough to flush the cuttings off the bottom in time and rush them to the surface reliably. Generally, for geological core drilling, the velocity of return is about 0.4 ~ 1.0 m / min.

Pressure: It depends on the depth of drilling, the passage resistance and the nature of the flushing fluid. The deeper the hole and the greater the resistance, the higher the pressure.

Sucker rod pump manufacturers continue to actively explore innovation, the arrival of new technology will produce good economic benefits, especially the effect of energy saving will be particularly significant.

Saigao Group is one of the leading gas & oil equipment suppliers in China. Leading products include various mud pumps, downhole motors, cementing tools, and various wellhead equipment.

20 years of professional experience allow us to better understand the needs of customers. We have a full set of production equipment, perfect detection methods and advanced technology. We always provide customers with good products and technical support, and sound after-sales service.

- このできごとのURL:

コメント