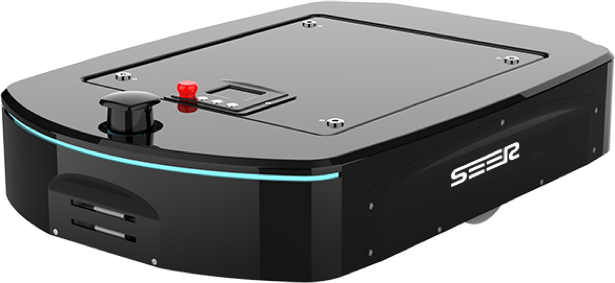

AMB Series Unmanned Chassis for AGV Autonomous Vehicle

(2022年04月08日)https://www.seer-group.com/robot/AMB

AMB Series Unmanned Chassis AMB (Auto Mobile Base) for agv autonomous vehicle, a universal chassis designed for agv autonomous guided vehicles, provides some features such as map editing and localization navigation. This unmanned chassis for agv cart provides abundant extent interfaces such as I/O and CAN to mount various upper modules together with powerful client software and dispatching systems to help users quickly complete manufacture and application of agv autonomous vehicles. There are four mounting holes on the top of the AMB series unmanned chassis for agv autonomous guided vehicles, which supports arbitrary expansion with jacking, rollers, manipulators, latent traction, display, etc. to achieve multiple applications of one chassis. AMB together with SEER Enterprise Enhanced Digitalization can realize the unified dispatching and deployment of hundreds of AMB products at the same time, which greatly improves the intelligent level of internal logistics and transportation in the factory.

Descriptions of AMB Series Unmanned Chassis for AGV Autonomous Vehicle

Rich features available at any time

Comprehensive and excellent standard features and rich and practical advanced features help clients easily achieve intelligent logistics.

Multi-specification platforms available for expansion

It offers a wide range of expansion platforms from 150 kg to 500 kg to meet the load and scenario requirements of different industries. It can also be used with manipulators, rollers, jacking, latent traction, pan/tilt, display screen, etc. to achieve multiple applications with one chassis.

±5 mm, efficient and accurate

Laser SLAM algorithm is used to achieve high-precision localization, with the laser non-reflective repeated locating accuracy within ±5 mm, enabling seamless docking between mobile robots and between mobile robots and humans, and efficient flow of cargoes among various points. Note: Actual values depend on environmental conditions

Stable navigation for safety and reliability

Network stability When there are multiple APs at the user site, the mobile robot can perform fast and stable roaming switching among multiple APs with optional industrial-grade Wifi client module that supports roaming to ensure the stability of the scheduling system connection.

Navigation stability Multiple navigation approaches ensure stable operation of the mobile robot.

3D obstacle avoidance A 3D vision sensor is added to identify and detect some three-dimensional obstacles (such as too low or too high obstacles, potholes on the ground, etc.) and choose to stop or bypass according to the configuration.

Easy deployment and visible management

SEER Enterprised Enhanced Digitalization, SEED easily enable mobile robot operation, dispatching and information management, and seamlessly connect with the plant's MES system to truly achieve intelligent logistics.

Specifications of AMB Series Unmanned Chassis for AGV Autonomous Vehicle

AMB Series Unmanned Chassis for AGV Autonomous Vehicle

Add products

AMB-150 | AMB-150-D

Basic parameters

Navigation methodLaser SLAM

Drive modeTwo-wheel differential

Shell colorPearl white / Pearl black / Customized color

L*W*H800*560*200mm

Rotation diameter840mm

Weight (with battery)66kg

Load capacity150kg

Chassis ground clearance25mm

Laser scanning height228mm

NetworkEthernet / Wi-Fi 802.11 a/b/g/n/ac

Temperature and humidity rangeTEMP: 0-50℃ / RH: 10-90%, no compression, no condensation

IP rating[1]IP20

Performance parameters

Passability (slope/step/gap)[2]≤ 5%/5mm/10mm

Minimum passable width700mm

Navigation position accuracy[3]±5mm

Navigation angle accuracy[3]±0.5°

Navigation speed≤ 1.4m/s

Map area (single frame)≤ 400000m²

AMB series products are certified to EN ISO 12100, EN 60204-1, EN1526 and EN ISO 10218-2.

Built-in batteries of AMB series products are certified to PSE and granted UN38.3 conformity report for air, sea & land transportation as well as MSDS report.

AMB series products are tested to ESD by relevant authority.

AMB series products conform to EU's REACH Directive.

AMB series products are certified to RoHS for human health and environment protection.

The traction when using latent traction or hook. The friction coefficient is affected by the ground and the material of the universal wheel. Here, μ = 0.1 is taken as an example. If a weight is added to the car body, the traction can be increased to some extent (AMB300 is able to provide up to 500 N traction after a weight is added).

The road surface should be smooth, clean and free of obvious ups and downs. Slope 5% = arctan (0.05) ≈ 2.8°. The robot must not stop or turn at the ramps, steps, or gaps, but can pass quickly perpendicular to them.

The localization accuracy is affected by the environment, etc., subject to the interpretation of localization accuracy in the final technical agreement.

The basic features include but are not limited to map editing, model editing, positioning module, navigation module, basic motion model (differential), peripheral extension features (robot arm, roller, jacking, latent traction) and API interface.

It needs to be used with the automatic charging pile of SEER.

It needs to be used with a latent traction or jacking extension module.

A 3D camera needs to be installed in the peripheral extension for the feature.

AMB is designed for indoor transportation only and is not recommended for outdoor use.

Asa professional amb factory, we provide agv reach truck, laser guided agv, amb in car, amr vs agv and etc. Want to know more? Contact us.

- このできごとのURL:

コメント