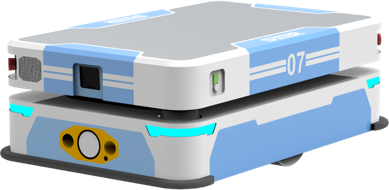

AMB-XS Series Unmanned Chassis for AGV Automated Guided Vehicle

(2022年04月08日)https://www.seer-group.com/robot/AMB-XS

AMB-300XS (Auto Mobile Base) for AGV automated guided vehicle is a universal chassis designed for the AGV robotics based on laser SLAM. This unmanned chassis for AGV auto guided vehicle provides some features such as map editing and localization navigation and has abundant extent interfaces such as I/O and CAN to mount various upper modules together with powerful client software and dispatching systems to help users quickly complete manufacture and application of AGV automated guided vehicles. This unmanned chassis AGV auto guided vehicle has passed CE certification (ISO 3691-4:2020) and SEMI safety assessment, which can provide customers with the highest level of health, quality, safety and environmental protection in the semiconductor field.

Descriptions of AMB-XS Series Unmanned Chassis for AGV Automated Guided Vehicle

Designed specifically for the semiconductor industry

It can be used in the semiconductor industry and has passed CE certification ISO 3691-4:2020 and SEMI safety assessment.

Body stability

The cantilever bridge structure ensures the wheels always touch the ground. Such stable AGV body is suitable for the application of composite robots.

Brand new industrial design

AMB-J is more practical, beautiful and economical.

Stable navigation for safety and reliability

Network stability When there are multiple APs at the user site, the mobile robot can perform fast and stable roaming switching among multiple APs with optional industrial-grade Wifi client module that supports roaming to ensure the stability of the scheduling system connection. Navigation stability Multiple navigation approaches ensure stable operation of the mobile robot. 3D obstacle avoidance A 3D vision sensor is added to identify and detect some three-dimensional obstacles (such as too low or too high obstacles, potholes on the ground, etc.) and choose to stop or bypass according to the configuration.

Easy deployment and visible management

SEER Enterprised Enhanced Digitalization, SEED easily enable mobile robot operation, dispatching and information management, and seamlessly connect with the plant's MES system to truly achieve intelligent logistics.

Specifications of AMB-XS Series Unmanned Chassis for AGV Automated Guided Vehicle

AMB-XS Series Unmanned Chassis for AGV Automated Guided Vehicle

Add products

Basic parameters

Product modelAMB-300XS

Navigation methodLaser SLAM

Drive modeTwo-wheel differential

Shell colorRAL9003

L*W*H845*585*300mm

Rotation diameter980mm

Weight (with battery)120kg

Load capacity300kg

Chassis ground clearance27mm

Laser scanning height185.5mm

NetworkEthernet / Wi-Fi 802.11 a/b/g/n/ac

Temperature and humidity rangeTEMP: 0-50℃ / RH: 10-90%, no compression, no condensation

IP rating[1]IP20

Performance parameters

Passability (slope/step/gap)[2]≤5%/5mm/30mm

Minimum passable width725mm

Navigation position accuracy[3]±5mm

Navigation angle accuracy[3]±0.5°

Navigation speed≤ 1.5m/s

Map area (single frame)≤ 400000m²

AMB-XS series products have passed CE-MD (EN ISO 3691-4:2020, EN 1175:2020, EN ISO 12100:2010,EN 60204-1:2018) certifications.

AMB-XS series products have passed CE-EMC (EN 61000-6-2:2005, EN 61000-6-4:2007+A1:2011, EN 12895:2015) certifications.

AMB-XS series products have passed CE-RED (EN 300 328 V2.2.:2019, EN 300 440 V2.2.1:2018) certifications.

Built-in batteries of AMB-XS series products are certified to PSE and granted UN38.3 conformity report for air, sea & land transportation as well as MSDS report.

AMB-XS series products are certified to TELEC wireless.

AMB-XS series products conform to EU REACH Directive.

AMB-XS series products are certified to RoHS for human health and environment protection.

AMB-XS series products are tested to ISO 14644 cleanliness for using in clean rooms of ISO Class 4 and below.

AMB-XS series products are tested to SEMI assessment for applications in semiconductor industry.

The traction when using latent traction or hook. The friction coefficient is affected by the ground and the material of the universal wheel. Here, μ = 0.1 is taken as an example. If a weight is added to the car body, the traction can be increased to some extent (AMB300 is able to provide up to 500 N traction after a weight is added).

The road surface should be smooth, clean and free of obvious ups and downs. Slope 5% = arctan (0.05) ≈ 2.8°. The robot must not stop or turn at the ramps, steps, or gaps, but can pass quickly perpendicular to them.

The localization accuracy is affected by the environment, etc., subject to the interpretation of localization accuracy in the final technical agreement.

The basic features include but are not limited to map editing, model editing, positioning module, navigation module, basic motion model (differential), peripheral extension features (robot arm, roller, jacking, latent traction) and API interface.

It needs to be used with the automatic charging pile of SEER.

It needs to be used with a latent traction or jacking extension module.

A 3D camera needs to be installed in the peripheral extension for the feature.

AMB is designed for indoor transportation only and is not recommended for outdoor use.

As a professional amb factory, we provide agv reach truck, laser guided agv, amb wholesale and etc. Want to know amr robot price or more? Contact us.

- このできごとのURL:

コメント