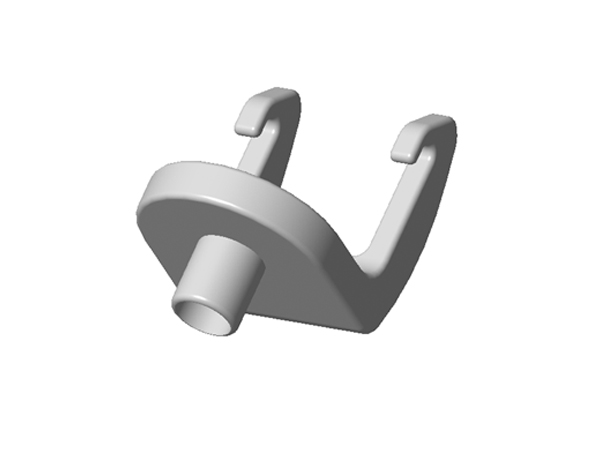

Machining Service In Medical Equipment Hardware

(2023年09月05日)https://www.sibaicnc.com/medical-precision-machining/

Compared with industrial hardware in life, medical equipment hardware has certain particularities, because medical equipment needs to be sterilized, and disinfection may be high-temperature disinfection. If it is long-term high-temperature disinfection, the requirements for medical equipment hardware are higher.

Features of Sibai Machining Capabilities in Medical Devices

The most common metal materials for cnc medical devices hardware are: Stainless steel and Titanium.

Stainless steel is one of the most commonly used metal alloys in the manufacture of surgical instruments. 316LVM stainless steel for surgical implants, Austenitic 316 (AISI 316L) steel is a commonly used stainless steel and is called "surgical steel" because it is a very corrosion resistant tough metal.

Titanium alloy has good biocompatibility, elastic modulus closest to human natural bone, and excellent wear resistance, corrosion resistance and formability. Therefore, Titanium alloy is one of the most promising biomedical materials and is very suitable for surgery. Instruments and Implants.

Sibai now has hundreds of high-tech advanced CNC lathes and CNC milling machines. Sibai has mastered mature and complete new processing technology in the processing technology of stainless steel and titanium alloy, and has formed an excellent technological team. Sibai has provided various high-precision and high-quality hardware accessories for a number of medical equipment customers.

Sibai is a professional precision cnc machining company, we provide medical device cnc machining, medical precision machining, cnc machining for medical industry, cnc machining medical devices, medical cnc machining, precision cnc machining service, etc. For more information, please feel free to contact us!

- このできごとのURL:

コメント