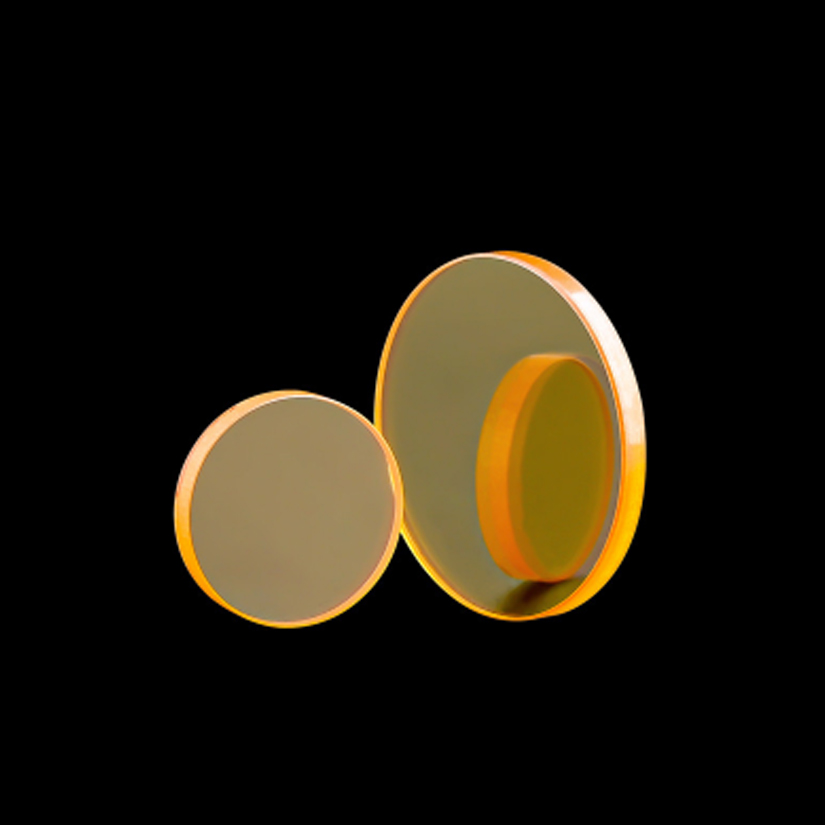

ZnSe Window

(2024年04月24日)https://www.tcoptik.com/products/znse-window.html

ZnSe Window

Our ZnSe Window is made with high-quality Zinc Selenide material, making it ideal for use in laser systems. The window ensures high transmittance in the infrared region, allowing for precise and accurate laser processing. ZnSe laser lens is well-suited for optical elements in high-resolution thermal imaging equipment. ZnSe also transmits some visible light, unlike Germanium and silicon, thereby allowing for visual optical alignment. However, zinc selenide window is quite soft and will scratch easily. ZnSe window has an index of refraction of 2.403 at 10.6 µm.

ZnSe Window Specification

Zinc selenide (ZnSe) windows are a popular choice for a wide range of applications due to their excellent optical properties, including high transmittance in the mid-infrared (IR) region and low absorption in the visible and near-IR regions. They are commonly used in scientific, medical, and industrial applications where optical clarity and high transmission are critical.

MaterialCVD ZnSe

Diameter1 to 500 mm

Diameter Tolerance+0/-0.02 mm

Thickness Tolerance±0.01 mm

Surface Quality10-5

Surface Figureλ/10

Parallelism1 Minute

CoatingUncoated, AR, HR, Beamsplitter, etc.

Our product is designed to withstand extreme heat, radiation and chemicals, ensuring durability and long-lasting performance. It comes in a range of sizes to cater for varying laser system configurations.

Types of optical window glass for your needs:

Fused silica window

Sapphire optical window

BK7 window

Germanium window

Silicon window

Borosilicate glass for sale

Float glass optical windows

With TC Optik's optical Window, you can expect superior performance, reliability and longevity - all at an unbeatable price point. Whether you're involved in research, development or industrial applications, our custom optical window is the answer to your laser processing needs. Get in touch with us today to learn more about our ZnSe Window and how it can benefit your laser system applications.

Properties and Characteristics of ZnSe Selenide Windows

Zinc Selenide windows are the best choice for a variety of IR applications and high-power CO2 laser systems. ZnSe has low IR absorption and high resistance to thermal application area. Zinc Selenide windows are best for thermal imaging. Zinc selenide windows are used in infrared imaging applications in scientific, military or search and rescue applications. ZnSe has a high index of refraction which requires an anti-reflection coating to achieve high transmission.ZnSe has good transmission from 3um-12um.Long wavelength transparency is crucial for imaging room temperature objects, which radiate at a peak wavelengths of approximately 10 µm with very low intensity.

Optical Properties

ZnSe windows have a high transmittance of over 90% in the mid-infrared (IR) region, making them an ideal material for use in IR spectroscopy and imaging applications. They also have low absorption in the visible and near-IR regions, making them an ideal choice for high-power laser applications.

Physical Properties

ZnSe windows have a low thermal expansion coefficient and a high thermal conductivity, which makes them an ideal choice for applications that require high thermal stability. They also have a low density and high hardness, which makes them resistant to scratching and other forms of damage.

Applications of ZnSe Windows

Infrared Spectroscopy

ZnSe windows are commonly used in infrared spectroscopy, where their high transmittance in the mid-IR region allows for accurate measurements of molecular vibrations and other spectral features.

Medical Imaging

ZnSe windows are also used in medical imaging applications, such as in endoscopes and other medical devices, where their high transmittance in the mid-IR region allows for detailed imaging of internal tissues and organs.

Laser Systems

ZnSe windows are used in high-power laser systems, such as CO2 lasers, where their low absorption in the visible and near-IR regions allows for efficient transmission of laser energy.

Industrial Applications

ZnSe windows find use in a variety of industrial applications, including gas analysis, semiconductor processing, and environmental monitoring, where their high transmittance and thermal stability make them an ideal choice.

Cleaning, Handling and Maintenance of ZnSe Windows

Proper handling and maintenance are important for maintaining the optical quality of ZnSe windows and ensuring their long-term reliability. It is important to avoid touching the surface of the window with bare hands or other objects, as this can leave oils or other contaminants on the surface that can degrade the optical quality. ZnSe windows should be cleaned using a mild detergent and water solution or with isopropyl alcohol, and it is important to use a soft, lint-free cloth or a lens cleaning tissue to avoid scratching the surface.

ZnSe is very soft material, so we should very careful about it. It requests professional people to make it clean. It is also a toxic material. Great care must be taken in handling and cleaning the material. Wear gloves at all times to avoid the risk of contamination. Hold only the edge to prevent scratches. Wash hands after use. when holding the optics by its edges. wipe the surface gently with a damp cotton ball. Do not rub, and do not exert pressure. use only surgical quality cotton balls.

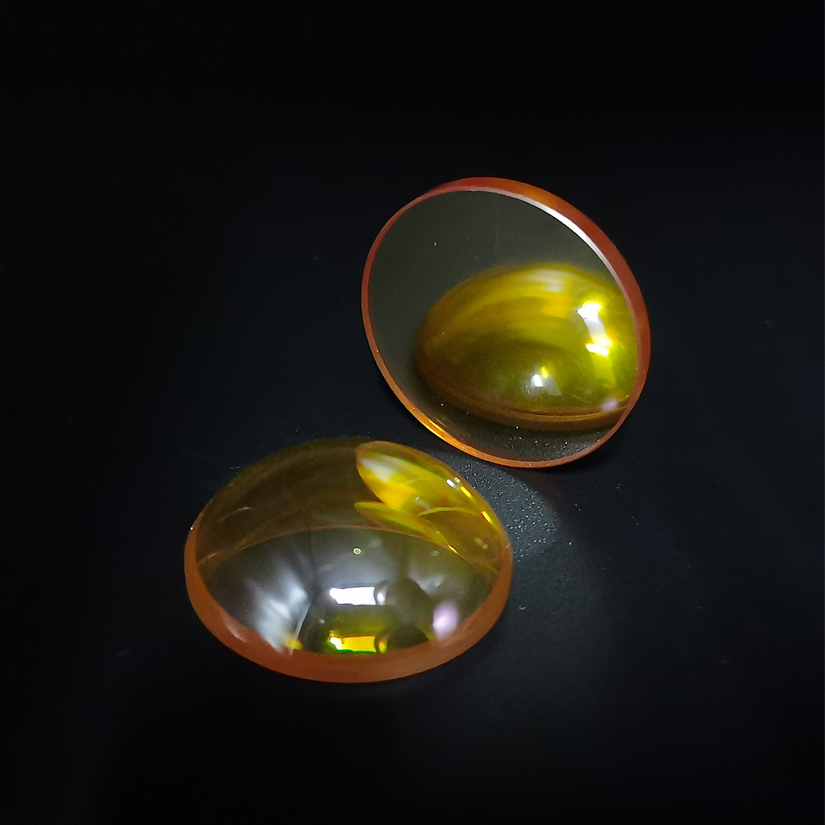

ZnSe focus lens VS ZnSe laser lens

ZnSe focus lens and ZnSe laser lens are both made of the same material, Zinc Selenide, which is commonly used in laser optics due to its high transmittance in the infrared region.

ZnSe focus lens is designed to focus the laser beam to a precise spot on the material being processed. It is used in laser cutting, engraving and marking machines where accuracy and precision are critical. The focus lens is adjustable, allowing the operator to adjust the focal length to match the thickness of the material being processed.

ZnSe laser lens, on the other hand, is a protective cover that is placed over the laser cavity to protect it from dust and debris. It is also used to block stray light from entering the cavity and interfering with the laser beam.

In summary, ZnSe focus lens is used to concentrate the laser beam to a pinpoint accuracy, whereas ZnSe laser lens acts as protection.

FAQs of ZnSe Selenide Windows

What is the refractive index of ZnSe?

A: The refractive index of ZnSe is about 2.4.

What is the thermal conductivity of ZnSe?

A: The thermal conductivity of ZnSe is about 18 W/mK.

What is the typical thickness of ZnSe selenide windows?

A: ZnSe selenide windows are available in thicknesses ranging from a few millimeters to several centimeters.

Can ZnSe windows be used in high-power laser applications?

A: Yes, ZnSe selenide windows have low absorption in the visible and near-IR regions, which makes them an ideal choice for high-power laser applications.

As one of znse window manufacturers, we will do our best to meet all the needs of customers.

If you want to know more about custom optical manufacturing, please contact us.

We can provide kinds of special optical component design for clients, anything you need, please leave us a message.

- このできごとのURL:

コメント