Machinery & Tools Inspection Service

(2023年03月12日)https://www.tradeaiders.com/third-party-equipment-inspection-service/

Mechanical equipment is composed of metal or other materials, by several parts assembled, in one or more power drives, which can complete the production, processing, operation, and other functions or utility device. Electrical equipment is divided into high voltage electrical equipment and low voltage electrical equipment according to voltage grade.

Dynamic machinery converts existing mechanical or other nonmechanical energy into available mechanical energy. Power machinery includes wind machinery, hydraulic machinery, thermal engine (gasoline engine, diesel engine, gas engine, steam turbine), electric motor, pneumatic motor, hydraulic motor, etc.

Energy conversion machinery that converts mechanical energy into some nonmechanical energy or USES mechanical energy to do a particular job. Energy conversion machinery includes a generator, heat pump, hydraulic pump, compressor, etc.

Service Content of Machinery Inspection & Tools Inspection Service

TradeAider will check the products based on common quality standard and customer requests, including but not limited to sampling inspection, graphic evidence, and quality report, and in the meantime keep all the inspection records block-chained and publicly notarized.

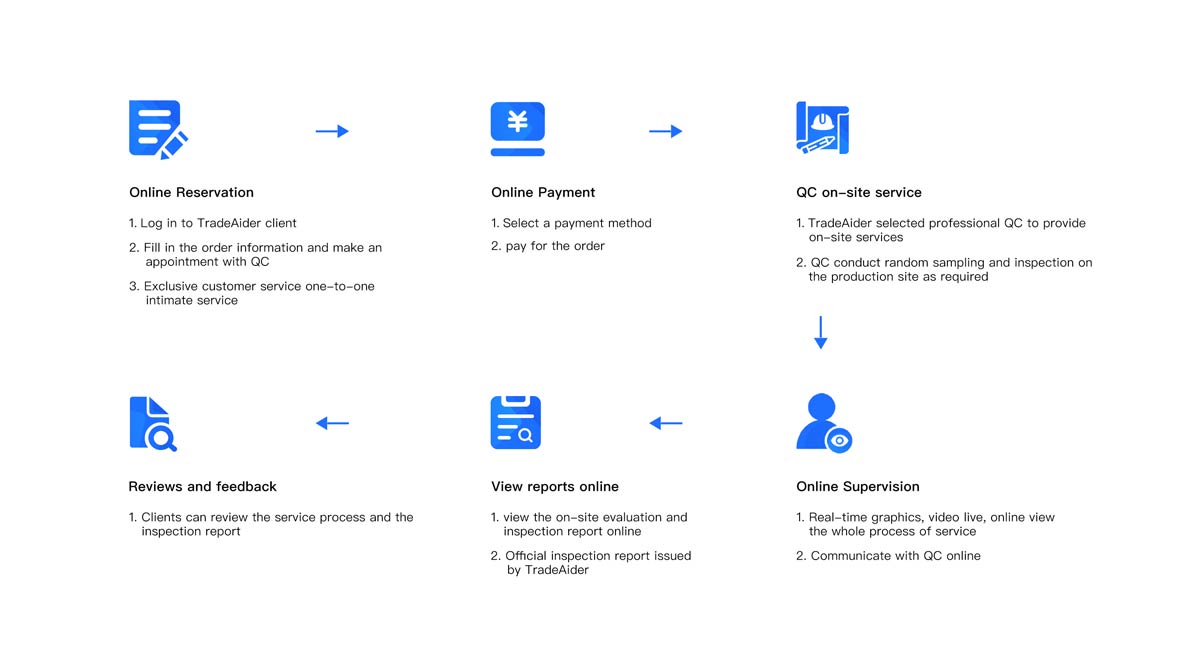

Service Process of Machinery & Tools Inspection Service

On-site Verification and Test of Machinery & Tools Inspection Service

- Test nameQuantity of

General testing of applicable products

1.Function test3pcs, At least 1 per style· No defect allowed

· There can be no functional loss after all the required number of times

2.Assembly test3pcs, At least 1 per style· No defect allowed

3.Critical components and internal check3pcs, At least 1 per style· No defect allowed

· No non-compliant component and safety issue

4.Earth continuity testAll samples· No defect allowed

· Europe: Measured resistance within limit

· USA: Good continuity.

5.Power measurementAll samples· No defect allowed

· Good continuity.

· Motor class power +20%

Power of heating class +5%~ -10%

6.HI-POT testAll samples· No defect allowed

· No insulation breakdown

7.Durability test3pcs, At least 1 per style· No defect allowed

· Work 4~6H

8.Thermostat function checkAll samples· No defect allowed

· Thermostat can reset after triggered

9.Stability test3pcs, At least 1 per style· No defect allowed

· No overturn or tip over

11.Motor speed test3pcs, At least 1 per style· No defect allowed

· Check whether speed is changed accordingly to different setting, the measured speed should be within the required range if speed specification is provided.

· Record measured data and whether using load

12.Thermal link function test1pc· No defect allowed

· Bypass any thermostat.

· Switch on the product until it reaches overload condition.

· Fuse shall work and no safety issue

13.Security check3pcs, At least 1 per style· No defect allowed

· No security failures

14.Material check3pcs, At least 1 per style· No defect allowed

· material should conform to the requirements

15.Hardness test3pcs, At least 1 per style· No defect allowed

· Hardness to be up to standard

We can offer great textile inspection services and third party equipment inspection for clients, anything you need, please contact us.

Like your extended office in China, TradeAider provides innovative one-stop trading solutions including Sell in China, WeGuarantee, WeSource, and the value-added services of WeFinance and NoFake, building a wonderful trade channel for you from outsourcing garment manufacturing to third party quality assurance and selling products in China, which helps grow your margin by over 20% and greatly promote your sales and brand value by introducing your brand and products to the vast Chinese market. In the meantime, TradeAider’s WeGuarantee service helps you control the product quality throughout the entire production process and ensure no quality issue will occur, which is a much better quality assurance service than the traditional third party inspection agencies.

- このできごとのURL:

コメント