Alloy Steel Fabrication

(2023年10月02日)https://www.walkson.com/alloy-steel-fabrication.html

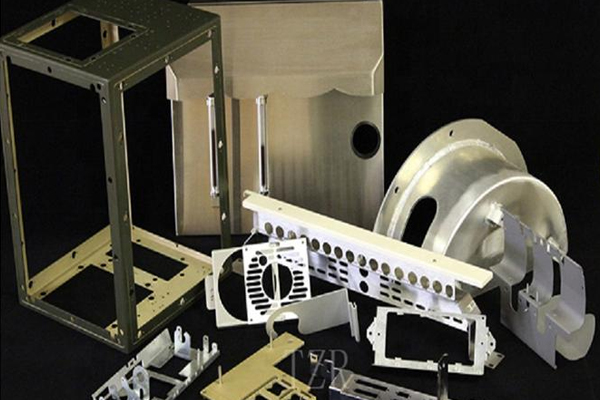

Alloy steel fabrication include the process of cutting, bending, shaping, assembly, welding all kinds of components together to making a products.

WALKSON, a reliable steel fabrication exporter, with decades alloy steel fabrication experience in all the process, has professional technical people, who have strong skills of alloy steel fabrication to making raw material to final products.

Material we can do but not limited:

AISI 4130, AISI 4140, AISI 4330, AISI 4340, AISI 8620, AISI 8630, AISI 9310, Nitralloy 135

Characteristic Analysis of Closed-Die Forging

What is closed die forging?

Closed die heavy forging is a type of forging process in which the dies move towards each other, encompassing the entire or part of the workpiece. The heated raw material, close to the shape or size of the finished forged piece, is placed in the lower die. The shape of the forged piece is negative and inserted into the upper or lower die. The impact of the upper die on the raw material from above shapes it into the desired forging shape.

Characteristics of closed die forging

Compared with open die forging, closed die forging has the following characteristics:

1. High metal utilization rate: Closed die forging produces little or no metal flash, and the forging inclination angle is generally 1°-3° or even no inclination angle, which can increase the metal utilization rate from 25%-70% to 50%-85%.

2. High forging quality: The forged pieces produced by closed die forging are very close to or even identical to the finished products in shape, with the metal fiber flowing completely with the shape. Deformed metal flows in the three-dimensional stress state, which is conducive to improving the plasticity of the metal material and effectively preventing the occurrence of loose tissue inside the forged pieces, resulting in higher mechanical performance.

In addition, since there is no metal flash, there is no fiber exposed due to cutting, which is advantageous for materials and parts exposed to stress corrosion.

3. Save machining costs: closed die forging parts have small tolerances and no residual flash left when cutting, thus effectively reducing subsequent machining time, reducing machine tool and tool consumption, and saving machining costs.

4. Lower mold life of closed die forging molds: For some small forgings, whether it is integral concave mold closed die forging or detachable concave mold closed die forging (complex-shaped forgings), the heat absorption and dissipation of molds during closed die forging is basically balanced, and the mold life is higher than or at least equal to that of open-die forging molds. However, for some medium or large forgings, the mold temperature rises quickly and wears out quickly during closed die forging, so the mold life is generally lower than that of open-die forging molds.

WALKSON is a professional supplier of casting, forging, and manufacturing products. The industries we serve include mining, mineral processing, and the oil and gas industry. Materials include carbon steel, low-alloy steel, high-chromium white cast iron, high-manganese steel, stainless steel, high-temperature alloy, titanium alloy, metal-ceramic composite materials, and bimetallic composite materials. We are committed to providing you with high-quality products and services for your design and specifications. Max. casting weight can reach 20 tons/piece, and forging weight can reach 80 tons/piece. Welcome to inquire.

What Is Closed Die Forging?

What is closed die forging?

Closed die forging, also known as impression die forging, is a forging process in which the metal flow and filling take place entirely within a closed die. This means that the deformed metal cannot exit the die, and the volume of the metal remains constant within the cavity. As a result, the metal is forced to flow and fill the cavity, which only produces small amount of flash without any burrs. Therefore, closed die forging is also known as flashless forging.

During closed die forging, no flash groove is needed, which reduces the amount of flash material and eliminates the need for flash trimming equipment. Closed die forging can achieve high precision and is suitable for forging disc-shaped or axisymmetric short shaft type parts. However, it requires high precision in cutting the raw material, which limits its applications.

What is the process of metal flow in closed die forging?

The process of metal flow in closed die forging can be divided into three stages:

The first stage is the basic forming stage. During this stage, the workpiece begins to deform and fill the cavity, and the increase in deformation force is relatively slow. Depending on the nature of the forging, this stage can involve upsetting, pressing, punching, or extruding.

The second stage is the filling stage. During this stage, the deformation force increases by 2-3 times compared to the first stage, but the deformation amount ΔH2 is relatively small.

The third stage is the formation of vertical flash. At this stage, the workpiece has already become a rigid body and further forging pressure is needed. The pressure can fracture the cast structure of dendrites, compact the porous structure, and produce vertical flash at the end of the workpiece. The thinner the flash, the higher the height, and the greater the compressive stress on the sidewall of the cavity. In severe cases, it can lead to the damage of the cavity.

The characteristics of closed die forging are as follows:

(1) It eliminates the use of flash material and the flash trimming process.

(2) Materials deform within the closed cavity with significant three-dimensional compressive stress, which enhances plasticity and is advantageous for low ductility materials.

(3) The flow lines are more reasonable, which improves mechanical properties of forgings.

(4) The size of the raw material and the positioning within the cavity must be accurate, it is difficult to remove the forging from the die, and a knockout mechanism needs to be designed to facilitate the removal of the forging from the die.

(5) Its application is limited and is mostly suitable for disc-shaped or axisymmetric short shaft forgings.

- このできごとのURL:

コメント