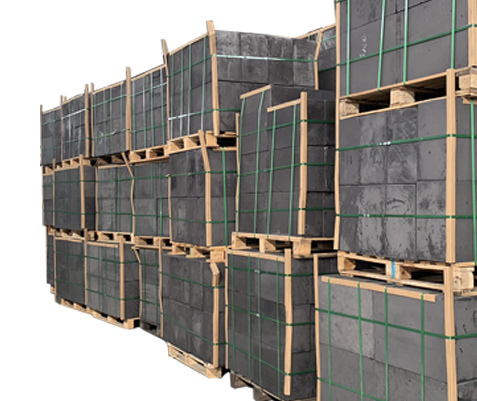

GRAPHITE MOULD FOR CASTING

(2023年01月12日)https://www.whgraphitesupplier.com/graphite-molds-for-casting.html

Artificial graphite is considered to be the most suitable material for the continuous or semi-continuous casting of non-ferrous metals. Production practice has proved that using graphite mould continuous casting industry, because of its good performance of thermal conductivity, thermal conductivity performance determines the speed of solidification of the metal or alloy), mold good self-lubricating performance factors, not only make the casting speed, and due to the size of the graphite blocks for casting precision, smooth surface, uniform crystal structure, can be directly for the next working procedure of processing. This not only greatly improves the rate of finished products, reduces the loss of waste, but also greatly improves the quality of products.

Graphite Mould for Casting Benefits

The coefficient of thermal expansion is an important factor to determine the use of graphite as die material. Molds are media with very heterogeneous temperatures, hot from the inside due to the molten material and cold from the outside due to the cooling process applied to them. The low thermal expansion coefficient exhibited by graphite enables the die to function without deformation or cracking. Another very important factor is self-lubrication. Graphite is a solid lubricant that creates low friction between the mold and the casting material. The graphite can then be smoothly extracted from the casting.

Graphite Mould for Casting Factors

There are many factors that determine the life of continuous casting graphite dies. The composition of casting material, to casting temperature, to cooling rate, will affect the life of graphite mold. The specific graphite grade used is also determined by a number of factors. The main factor is what kind of material technology is to be used in the graphite mould casting. For example, for gray cast iron or high-nickel alloys, wear-resistant graphite is required, while for brass, relatively dense graphite with sufficient porosity to allow zinc to evaporate would be a better choice.

As a professional graphite products factory, we provide graphite mould, carbon graphite crucible, graphite production in china, etc. want to know more, contact us.

- このできごとのURL:

コメント