Plastic CNC Machining

(2023年02月20日)https://www.xinpinmodel.com/plastic-cnc-machining/

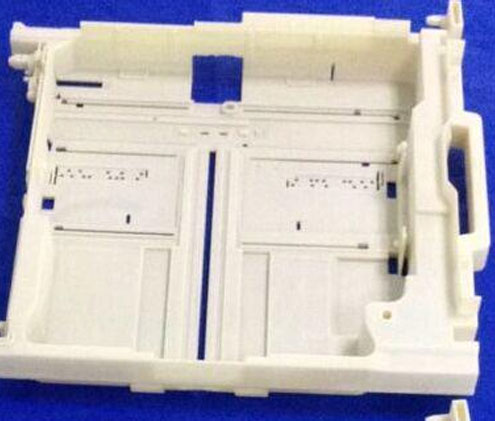

China Plastic Machining Services

As the raw material cost rising, the demanding of the plasctis parts machining is increasing. Different material require different programming and processing machining. It is very different from metal machining.

Xin Pin provide china plastic cnc machining service. Our capability enables us to meet your demanding requirements with our superior equipment, tools, cutters and professional technician. And we conduct whole process including the after-treatment and inspection to ensure quality.

Why Choose CNC Plastic Machining At Xin Pin

Xin Pin is one of the leading plastic cnc machining supplier in China. The following capability helps us to satisfaction with your on-demanding manufacturing.

We got ISO 9001 certified. Our advanced quality control processes with well-equipped quality assurance department and a quality management system.

Fully-equipped CNC plastic machines to handle any type of project. Our comprehensive machining capabilities ensure that we can make different kinds of parts with complex parts.

The wide range of material selection. We can produce plastic parts from all types of plastic.

Our Professional technician team has a good command of the machining processing that the parts will be machined in an integrated plan to machine 100% perfect part.

Common Using Plastic Material We Use

1. ABS

ABS is a popular engineering thermoplastic known for its impact strength and resistance, high heat resistance, and good machinability.

Mechanical specifications:

Elongation at Break: 10 – 50%

Flexural Modulus: 1.6 – 2.4 GPa

Tensile Strength: 29.8 – 43 MPa

Hardness Shore D: 100

2. Nylon

Nylon, also known as polyamide (PA), is particularly well-suited for CNC machining because it's strong and durable enough for a wide variety of applications in many industries including automotive and medical devices.

Mechanical specifications:

Elongation at Break: 150 – 300%

Flexural Modulus: 2965 MPa

Tensile Strength: 76 MPa

Hardness: 116, Rockwell R

Plastic CNC Machining Process

There are three most common techniques are turning, milling, and drilling for plastic CNC machining.

Plastic CNC turning– It is always shaped by Lathe. Lathes can process various kinds of plastic materials. Material is rotated by a chuck while a tool is fed through the workpiece to remove material until the desired shape has been achieved.

Plastic CNC drilling–As drilling is a very simple process, it is easy to be done by lathe and mills. Material is fixed to a table while a drill tool is rotated into the workpiece to bit bores in a plastic part.

Plastic CNC milling – Material is fixed to a sliding table while a spindle equipped with cutting tools is raised and lowered to machine complex forms. The milling is carried out by using milling machines or machining centers.

FAQ of Plastic CNC Machining Services

1 Can plastic be CNC machined?

Yes, it is a very ideal material for prototyping and mold manufacturing.

2 What is the best plastic to CNC?

3 What is the maximum size of the plastic parts and small series you can produce by CNC Machining?

4 What is CNC plastic machining?

5 Can I supply my raw material for plastic CNC machining services?

For more information about cnc machining types, please feel free to contact us!

If you need any kinds of cnc machining services, please contact us, as a professional machining services manufacturer, Xin Pin is willing to offer you high quality products.

- このできごとのURL:

コメント