Rapid Injection Molding

(2023年08月01日)https://www.xinpinmodel.com/rapid-injection-molding/

What is Rapid Prototyping China Injection Molding?

China rapid injection molding is the rapid tooling technique by the infusion of plastic into the steel cavity mold which is a common use for making high-quality end parts production. It is the most efficient way to produce plastic parts in high volumes for commercial and functional using.

As one of professional rapid injection molding factories, we offer machining and finishing services to make tools from a wide range of materials and can produce 50 to 100,000+ finished parts. With our material verification and quality processes, we can ensure your tools and parts are out of your expectations.

Specification of Rapid Injection Molding

Name

Description

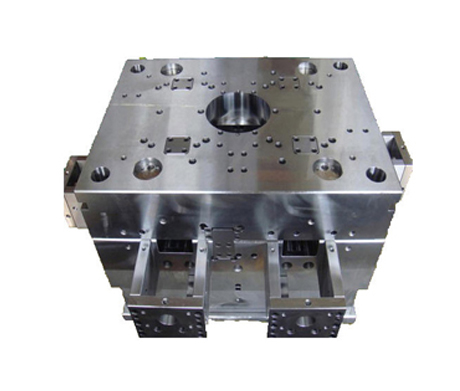

Mold Material

Tool Steel P20, Carbon Steel S50C, Aluminium

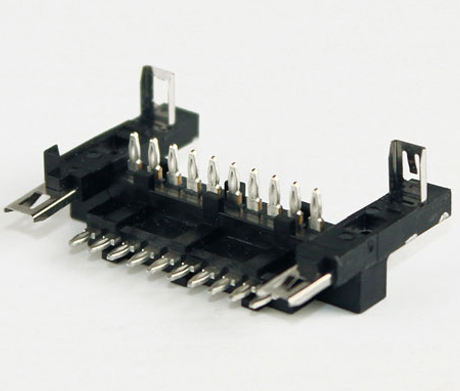

Injection Mold Services Category

a. Rapid Tooling

Molds with steel cavity and core with a short life of 5,000-10,000 times which normally machined in 2 weeks.

b. Multi-calvity or Family Molds

Multiple identical cavities or family of parts machined into a single tool, Allows for more parts to be produced per shot, minimizing unit costs

c. Insert Molding

Inserts are placed into the mold and molding occurs around them to extend tool life for critical features. Allows for inserts such as helicoils to be molded in your design.

Standard Tolerance

+/-0.010mm

Production Time

As low as 2 weeks for building mold and the first sample part.

After sample approval, lead time for < 10,000 parts is as low as 1 week.

Lead Time

Starts at 10 business days, including 24-hour quote responses with design-for-manufacturing (DFM) feedback.

Quality Assurance

DFM analysis, moldflow, CAE, control plan, PSW inspection reports included, full dimensional report and material certifications available upon request, PPAP submitted after starting the production.

Reorder

Unit price is based on the quantities required and an additional setup fee of $150 USD.

Rapid Injection Molding Process

China rapid molding process typically consists of the following step.

1. Mold Making

The mold will be done by CNC machining and EDM according to the structure of the parts.

2. Material Preparation

The Plastic resin comes from raw pellets.

3. Injection of Melted Resin

The heated mold closes automatically and resin, under great pressure, is injected through a gate and into the mold cavity.

4. Cooling and Solidification

The mold is cooled in a short amount of time to solidify the part inside.

5. Injection of Final Part

The mold opens and the part is ejected to begin a new cycle.

Advantage of rapid heating and cooling injection molding prototyping

1. Economical And Pratical

We offer a free design-for-manufacturability analysis to make production optimization for improving our customer profit and minimizing losses.

2. A Wide Variety of Plastic Materials

There are thousands of different types of materials to choose from that enable you to achieve your need for your design.

3. Long Term Mold And for Production

Normally 100000+ lifetime that you can repeated use to make parts.

4. Premium Quality And Precision

As one of the certified rapid injection molding suppliers, all our parts follow a stringent in-house quality control service that ensures that we deliver the best.

- このできごとのURL:

コメント