CNC Machining Material

(2023年06月06日)https://www.xinpinmodel.com/cnc-machining-material.html

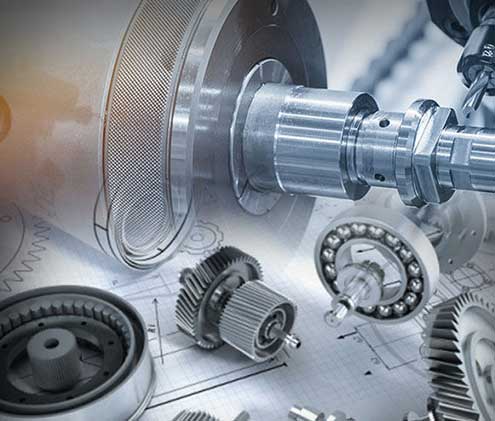

What is CNC Machining Material?

Choosing the right material is an important step to your prototyping production. Thousands of different types of materials are used for prototyping, but only one of them will be the best choice for your product.

Xin Pin aim of offering outstanding service to our customer by using the best raw manufacturing material, covering plastic, metal, and urethane. We also provide material inspection certificates to all our clients as the first step in our quality control and assurance process. Below, please review some information on our available materials. If you have any customed material requirements, please not hesitate to talk with us today!

3D Printing Construction Materials

Metal Manufacturing Overmolding Materials

Depending on your choice, we can work well on the project on different materials with different manufacturing processes.

Aluminum Material

Aluminum is a very popular material by its high thigh machinability, good strength, corrosion resistance, and low cost that the variety of manufacturing processes applied.

The favorite processes are sheet metal fabrication, CNC machining, die casting, and extrusion.

Application in Automatic Mechanical Parts, Precision Parts, Mold Manufacturing, Electronics, And Precision Instruments.

Steel Material

Steel is one of the most versatile engineering materials with excellent mechanical attributes, part accuracy, and high repeatability. It has high strength, wear and impact resistance and can be used in extreme load conditions.

Steel can be processed by CNC machining, welding, and stamping.

It's a strong material used in construction and heavy load machinery components.

Stainless Steel Material

Stainless steel is high strength and hardness, Corrosion resistant, Non-magnetic, Chemical resistant. Heat resistant. The properties increased compared with the steel material.

Stainless Steel can be processed by CNC machining, welding, and stamping.

Due to its high corrosion resistance, stainless steel is perfect for use for outdoor applications, the marine industry, and the chemical industry.

Titanium Material

Titanium is commonly used in aerospace and automotive bodies, as well as orthopedic applications in the medical and dental industries. It is strong, high-temperature resistance, corrosion-resistant, sterilizable and bio-compatible.

Manufacturing processes include sheet metal fabrication, laser cutting, CNC machining, friction welding, and profile extrusion.

CNC Plastic Material

Plastic casting material and rubber casting material is more cost-effective with good sculpturability compared with metal material. We can work on them with various kinds of color and physical property.

ABS Material

ABS is one of the common use materials in prototyping. For its lightweight, High stability, Common thermoplastic, impact-resistant, easy to machine and do the assembly and split, and easy to adhesive.

It's very popular in 3D printing and widely used for injection molding, CNC machining, injection mold, and vacuum casting manufacturing.

Polycarbonate

Toughness, more durable and strong than PMMA., But thick areas can have defects such as voids, bubbles, and sink. And it is better known for manufacturing transparent parts with its acceptable rigidity and toughness.

It always applies for CNC machining, vacuum casting, injection molding and it requires a hard coating to provide scratch resistance.

Applications in safety glasses, bulletproof barriers, and components for the marine automotive, and aerospace industries.

3D Printing Material--Urethane

As machining services factory, we have different types of urethane materials for vacuum casting services. We also provide flexible urethane for clients looking for custom prototyping and low-volume productions. Our urethane parts can be finished with our standard specifications, or customized to meet the needs of your part through texturing and installations.

Hei-Cast PU8400

Hei-Cast 8400 is a very good flow-ability and curing property. It is a colorless and transparent soft rubber material.

It is always used for vacuum casting.

There are widely used as prototype models, food samples, vehicle parts, potting, and doming applications.

EPDM

EPDM is torn resistance, high tensile strength, and low compression material.

It is always used in the plastic injection mold process.

Application in the automotive gasket.

Besides, rubber, silicon, transparent PU elastomer, and so on with different kinds of selection in your prototype and production manufacturing.

- このできごとのURL:

コメント