Busbar Bridge Seam Finding

(2023年04月14日)https://www.intelligent-laser.com/busbar-bridge-seam-finding.html

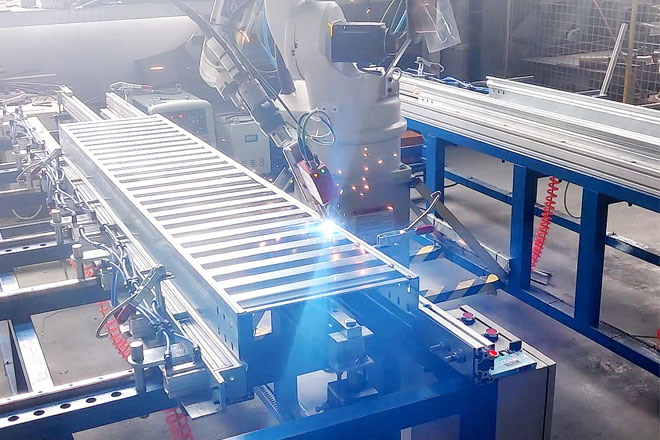

Product model: IL-HSP series

Matching equipment: OTC robot

CASE ANALYSIS

Customer pain points:

There are problems such as blanking error, clamping error, stress deformation and so on.

Implementation plan:

KUKA robot is equipped with laser vision seam tracking system welding, and the positioning function is used to correct the welding track and improve the welding accuracy.

Application effect:

Welding efficiency and welding quality have been greatly improved.

Laser seam tracking system is mainly composed of a laser sensor and a host control unit. The laser sensor is used for activating collection of seam information. The host control unit is responsible for real-time processing of seam information, and maintains real-time communication with industrial robots or special welding machines. Correct the programmed path of the robot or special machine during welding to ensure that the weld is accurately deposited on the joint. Laser vision system includes 5 main application branches and more than 10 product models, which can suitable for more than 30 robot brands. Meanwhile, it's Finding/Seam Tracking/Pre-Scanning/Adaptive Tracking function can meet the needs of intelligent welding.

- このできごとのURL:

コメント