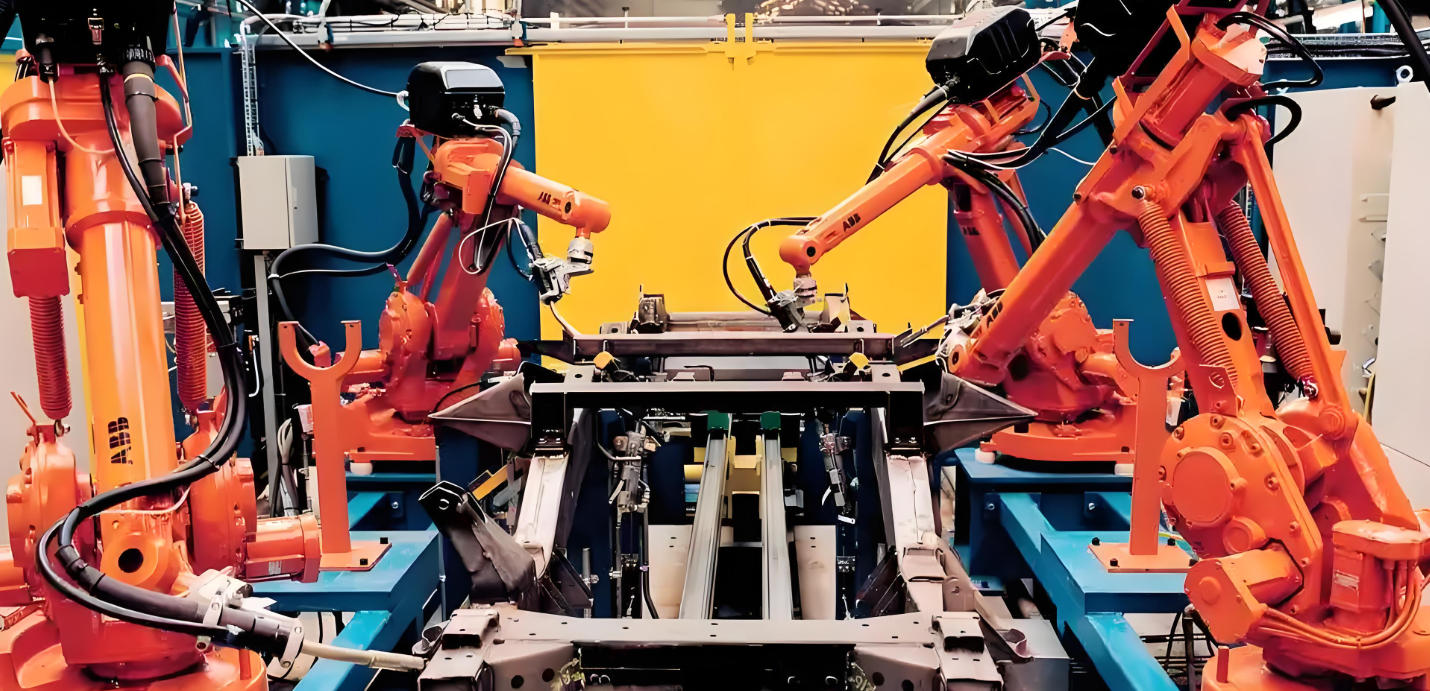

TOF Depth Cameras in Industrial Robots: Precision and Safety

(2025年09月15日)1. Background: The Need for 3D Perception in Industrial Robots

In the era of Industry 4.0 and smart manufacturing, industrial robots are no longer limited to repetitive automation. They are evolving into high-precision, intelligent systems capable of flexible and adaptive operations. Traditional robots that rely on 2D vision or basic sensors face major challenges in complex production environments:

Limitations of 2D vision: Depth estimation errors arise under variable lighting, occlusion, reflective surfaces, or multi-object conditions, leading to failed grasps and higher collision risks.

Lack of spatial understanding: 2D cameras capture color and brightness but cannot represent object depth, making it difficult to determine positions and orientations in 3D space.

Poor adaptability to dynamic environments: High-speed assembly lines, moving workpieces, and human-robot shared spaces demand reliable spatial awareness that 2D systems cannot consistently deliver.

By contrast, Time-of-Flight (TOF) cameras measure the round-trip travel time of light pulses to generate millimeter-level depth maps in real time. With stable and accurate 3D sensing that is immune to lighting conditions, TOF empowers robots to perform safely and efficiently in dynamic, complex production environments. This positions TOF as a cornerstone technology for the smart factories of tomorrow.

2. The Role of TOF Cameras in Precise Positioning

Positioning accuracy directly determines robotic performance in tasks such as gripping, handling, and assembly. TOF depth cameras deliver critical advantages:

High-Precision 3D Coordinate Acquisition: TOF generates dense point clouds, providing accurate object location, orientation, and dimensions for precise operations.

Real-Time Tracking of Moving Objects: Even on fast-moving conveyor belts, TOF continuously updates target positions to ensure smooth, consistent performance.

Higher Grasping Success Rates: Combined with AI-based grasp planning, TOF data reduces errors, collisions, and downtime, enhancing productivity.

Robust Operation in Challenging Conditions: Unlike 2D systems, TOF is not dependent on ambient light, performing reliably under strong glare, low light, or partial occlusions.

Integration with AI and Edge Computing: Robots can learn, optimize, and adapt, moving from rule-based execution to autonomous decision-making and collaboration.

Example: In electronic component assembly, reflective metal surfaces often confuse traditional vision systems. TOF cameras, however, capture precise 3D data, enabling stable alignment and assembly, reducing defect rates.

3. Obstacle Avoidance and Path Planning in Industrial Environments

Safety is just as critical as precision. Robots must navigate complex factory layouts filled with equipment, materials, and moving personnel. Traditional sensors are prone to blind spots and delays, while TOF cameras provide real-time 3D spatial awareness that underpins advanced obstacle avoidance and navigation:

Instant Depth Data Acquisition: Robots detect static objects, moving workpieces, and human presence in real time to prevent collisions.

Autonomous Navigation for AGVs: Automated Guided Vehicles use TOF-generated 3D maps to move safely through cluttered layouts, avoiding machinery and workers.

Dynamic Path Optimization: Constantly updated TOF depth data allows robots to adjust trajectories on the fly, minimizing energy use and mechanical wear.

Safe Multi-Robot Collaboration: In shared environments, TOF enables accurate monitoring of relative positions, reducing conflicts and downtime.

Reliable in Harsh Conditions: TOF maintains stability in dim light, bright glare, and highly cluttered production spaces.

Example: In logistics sorting centers, thousands of packages flow rapidly on conveyors. TOF cameras precisely measure parcel dimensions and positions while guiding AGVs to avoid obstacles—achieving high-speed, collision-free operations.

4. Balancing Cost and Performance

Adopting TOF technology requires weighing cost, performance, and ROI. Fortunately, TOF strikes an effective balance:

Cost-Effective Alternative to LiDAR: Smaller, lighter, and more affordable, yet capable of providing sufficient accuracy for most robotic applications.

Advantages Over Stereo Vision: Stereo vision requires dual cameras and heavy computation, while TOF uses a single camera to achieve stable, accurate depth sensing under all lighting conditions.

Flexible Deployment: Strategic placement minimizes blind spots while maximizing coverage, reducing hardware costs without sacrificing accuracy.

Energy Efficiency and Low Maintenance: TOF cameras consume little power, support long-term continuous use, and reduce maintenance downtime.

Scalability for Future Upgrades: Easily integrated with AI, multi-sensor fusion, and edge computing for evolving applications.

Example: Small and medium-sized manufacturers can replace costly LiDAR systems with TOF cameras for robotic arms or AGVs, achieving reliable performance at a fraction of the cost.

5. Future Trends: AI-Driven TOF for the Smart Factory

Looking forward, the integration of TOF depth cameras with AI, edge computing, and digital twins will transform industrial robots into intelligent, predictive, and collaborative systems:

Autonomous Learning and Decision-Making: AI interprets TOF data to recognize diverse object shapes, sizes, and orientations, autonomously plan paths, and continuously improve accuracy through experience.

Collaborative Robotics (Cobots): TOF provides shared spatial awareness for multiple robots and safe human-robot interaction, enabling dynamic task allocation and conflict-free collaboration.

Predictive Intelligence: AI models analyze TOF data to detect anomalies such as material blockages or equipment malfunctions before they disrupt production.

Digital Twin Integration: Real-time TOF data feeds into virtual factory models, supporting visualization, scheduling, and remote management of production systems.

Next-Generation Applications: TOF will enable unmanned warehousing, automated assembly, precision machining monitoring, predictive maintenance, and flexible scheduling.

In the near future, AI-powered TOF robots will evolve from passive task executors into intelligent collaborators, capable of optimizing efficiency, anticipating risks, and adapting to dynamic workflows.

6. Conclusion

TOF depth cameras are reshaping industrial robotics by providing real-time 3D spatial perception for precise positioning, intelligent grasping, safe navigation, and path planning. When integrated with AI, edge intelligence, and digital twin platforms, TOF empowers robots to achieve new levels of efficiency, adaptability, and safety.

As resolutions improve and algorithms advance, TOF will play an even larger role in Industry 4.0. The fusion of AI + TOF technology is set to become a driving force behind the evolution of smart factories—paving the way for intelligent, collaborative, and predictive robotic systems that redefine modern manufacturing.

Synexens Industrial Outdoor 4m TOF Sensor Depth 3D Camera Rangefinder_CS40

BUY IT NOWhttps://tofsensors.com/collections/time-of-flight-sensor/products/synexens-industrial-outdoor-tof-sensor-depth-3d-camera-rangefinder-cs40

After-sales Support:

Our professional technical team specializing in 3D camera ranging is ready to assist you at any time. Whether you encounter any issues with your TOF camera after purchase or need clarification on TOF technology, feel free to contact us anytime. We are committed to providing high-quality technical after-sales service and user experience, ensuring your peace of mind in both shopping and using our products

- このできごとのURL:

コメント