TOF 3D Inspection: Boosting Efficiency in Industrial Quality Control

(2025年09月17日)In today’s rapidly advancing industrial automation, quality control has become a defining factor of competitiveness. Traditional inspection methods—relying heavily on manual labor and 2D vision systems—struggle to meet the demands of high precision and efficiency in modern manufacturing.

With the rise of Time-of-Flight (TOF) 3D inspection technology, manufacturers now have access to a new generation of quality control tools that balance accuracy and precision, eliminate human subjectivity, and ensure faster, smarter defect detection.

This article explores how TOF 3D depth cameras are transforming industrial quality control, their advantages over traditional methods, real-world applications, and future development directions.

What is a 3D Depth Camera?

A 3D depth camera captures not just surface details like color and texture, but also the distance of every pixel from the camera, creating a 3D depth map or point cloud.

Common depth-sensing technologies:

TOF (Time-of-Flight): Emits infrared or laser pulses, calculates depth based on the time light takes to return.

Structured Light: Projects patterns on surfaces, then reconstructs depth from deformations.

Stereo Vision: Uses multiple cameras to calculate depth from disparities, similar to human vision.

Simply put, TOF cameras allow machines to “see” in 3D, enabling precise measurements and automated inspections in real-world industrial environments.

1. Current Challenges in Industrial Quality Control

Even with increasing automation, traditional methods face persistent issues:

Human Error: Manual inspections depend on worker skill and fatigue, leading to inconsistent standards.

Low Efficiency: Manual or 2D inspection cannot keep up with high-throughput production lines.

2D Limitations: Flat images miss dents, gaps, or misalignments that affect product integrity.

This creates bottlenecks in production and makes it difficult to achieve both accuracy (closeness to true values) and precision (consistency across repeated measurements).

2. How TOF Enables High-Precision 3D Inspection

TOF cameras calculate distance using the travel time of light pulses, generating real-time 3D point clouds of inspected objects. This allows comprehensive and reliable inspection directly on production lines.

Advantages of TOF in Quality Control:

Surface Defect Detection: Identifies scratches, dents, or burrs invisible to 2D systems.

Dimensional & Geometric Measurement: Measures length, width, height, and angles in real-time.

High-Speed Inspection: Operates seamlessly on fast-moving production lines.

Robust Performance: Works in varied lighting and dusty industrial environments.

TOF bridges the gap between accuracy vs precision, ensuring products meet design standards consistently and efficiently.

3. Real-World Applications

Electronics Manufacturing

Detects solder joint height, pin alignment, and micro-defects.

Ensures both accuracy (true defect detection) and precision (consistency across batches).

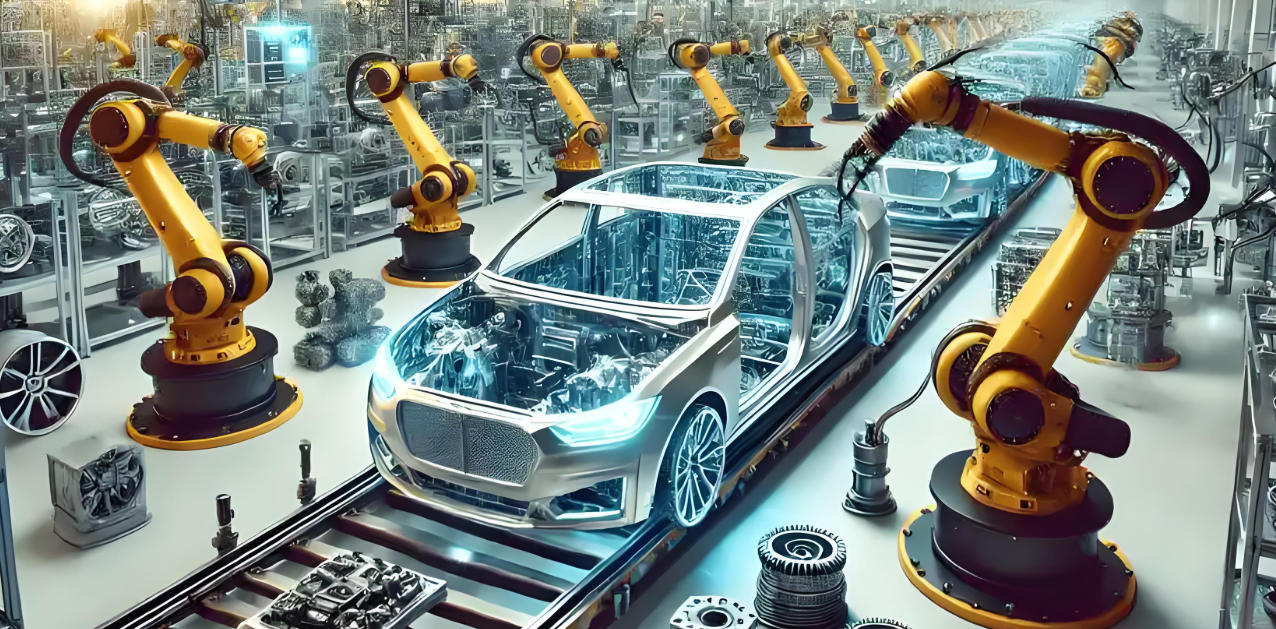

Automotive Parts

Monitors bolt hole alignment, weld depth, and assembly gaps.

Prevents safety issues by ensuring tolerances within 0.1 mm are detected.

Improves both yield and safety standards across production.

4. Comparison with Other 3D Inspection Technologies

TechnologyStrengthsLimitations

Laser ScanningHigh accuracy, micron-level detailToo slow and costly for mass production

Structured LightGood accuracy in controlled labsSensitive to lighting, slower data processing

TOF (Time-of-Flight)High speed, stable in varied environmentsSlightly less fine-grained than laser but optimal for mass production

Key insight: TOF provides the best balance of accuracy and precision for high-speed industrial production.

5. Future Development of TOF Inspection

Multi-Sensor Fusion: Combining TOF with RGB or infrared for richer inspections.

AI-Powered Quality Control: Predicting defects and enabling preventive maintenance.

Adaptive Inspection: Dynamically balancing speed vs precision based on production requirements.

In the era of Industry 4.0, TOF will evolve from simple defect detection to intelligent quality prediction and system-wide optimization.

Conclusion

TOF 3D inspection is revolutionizing industrial quality control by:

Eliminating human inconsistency

Combining speed with reliability

Achieving the ideal balance of accuracy vs precision

Supporting smarter, predictive, and adaptive manufacturing

As TOF integrates with AI, IoT, and big data, it will become a cornerstone of intelligent quality management, ensuring manufacturers achieve higher yields, safer products, and more efficient production lines.

✅ Featured Product: Synexens 3D RGBD ToF Depth Sensor_CS30

A professional-grade TOF depth camera designed for high-speed, high-precision industrial inspections.

Synexens 3D Of RGBD ToF Depth Sensor_CS30

SHOP NOWhttps://tofsensors.com/collections/time-of-flight-sensor/products/rgbd-3d-camera

After-sales Support:

Our professional technical team specializing in 3D camera ranging is ready to assist you at any time. Whether you encounter any issues with your TOF camera after purchase or need clarification on TOF technology, feel free to contact us anytime. We are committed to providing high-quality technical after-sales service and user experience, ensuring your peace of mind in both shopping and using our products.

- このできごとのURL:

コメント