Enhancing Efficiency and Precision in Production Line Quality Control with TOF

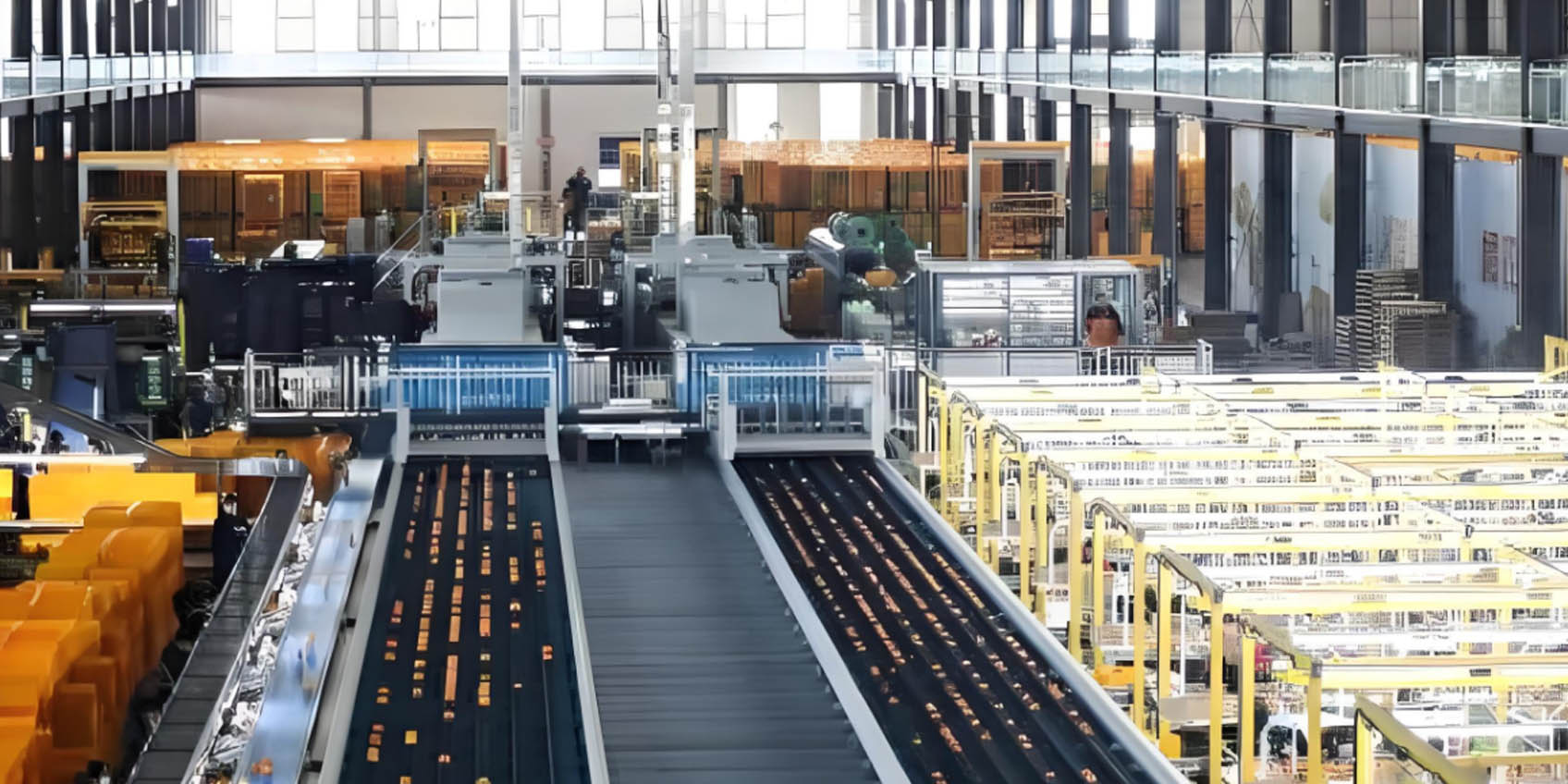

(2025年04月28日)With the growing emphasis on improving production quality and efficiency, TOF (Time of Flight) technology has become an essential tool for enhancing precision in manufacturing quality inspections. Offering high-accuracy distance measurements and real-time data capture, TOF sensors enable thorough inspection of products throughout the production line, ensuring adherence to stringent quality standards. This article delves into the benefits of TOF technology in production line quality control and how its integration with AI-driven visual inspection algorithms optimizes overall manufacturing efficiency.

What is a TOF (Time of Flight) Sensor?

TOF technology calculates the distance between an object and a sensor by emitting light pulses and measuring the time it takes for them to return. This allows for precise detection of object position and size in three-dimensional space, making TOF sensors ideal for high-precision applications. In manufacturing, TOF sensors are mainly used for detailed measurements of product dimensions, shapes, and positions, offering not just two-dimensional data but also comprehensive three-dimensional insights.

A key advantage of TOF technology is its independence from external light conditions, ensuring reliable performance in dynamic production environments. Whether under bright sunlight, dim lighting, or varying climatic conditions, TOF sensors maintain consistent and precise data output.

Benefits of TOF Technology in Production Line Quality Control

1. High-Precision Measurements for Enhanced Product Quality

TOF sensors deliver millimeter-level precision, crucial for ensuring product quality. In industries like electronics, TOF technology measures circuit board dimensions and the placement of solder joints, confirming that each product adheres to rigorous specifications. Similarly, in sectors like automotive and aerospace, TOF sensors ensure high-accuracy measurements of parts' dimensions, shapes, and positions.

2. Real-Time Monitoring and Automation

TOF technology supports real-time data collection during the production process, facilitating continuous high-frequency scanning and immediate detection of deviations. When paired with AI visual inspection algorithms, this data is processed instantly, enabling AI to automatically identify and categorize defects according to predefined criteria. This automation reduces the need for human intervention, enhancing production line efficiency and minimizing errors.

3. Robust Performance in Challenging Environments

Traditional optical sensors may struggle in complex environments with fluctuating light, temperature, or humidity. In contrast, TOF technology remains unaffected by changes in external light conditions, delivering precise and stable measurements regardless of the surrounding environment. Whether exposed to high temperature, humidity, or direct sunlight, TOF sensors consistently provide reliable data.

4. Boosting Production Efficiency

With AI visual inspection algorithms, TOF technology doesn't just measure dimensions—it also detects surface defects such as scratches, cracks, and dents. Using deep learning and image recognition, AI algorithms analyze the collected data, identifying potential issues in real-time. This rapid feedback accelerates the inspection process, reducing the reliance on manual checks and speeding up overall production.

Combining TOF Technology with AI for Smarter Quality Control

The integration of TOF sensors with AI visual inspection algorithms takes production line quality control to a new level of accuracy and automation. AI algorithms can analyze vast amounts of data and quickly make judgments on potential defects. For example, AI can identify dimensional discrepancies, shape irregularities, or surface damage based on the data collected during production, offering real-time corrections and feedback to operators.

Furthermore, AI systems can compare real-time data with historical records, product models, and process benchmarks, allowing for early detection of potential issues and preventative measures. This reduces the risk of defects reaching customers, improves product consistency, and enhances overall quality.

Applications of TOF Technology in Production Line Quality Control

1. Precision Inspection in Electronics Manufacturing

In electronics production, TOF technology ensures the precise measurement of circuit boards and components in real time. With AI algorithms, it detects minute surface defects like irregular solder joints or damaged circuits, ensuring optimal product quality and functionality.

2. Automotive Part Inspection

TOF sensors are widely used in automotive production lines for inspecting car body parts, engine components, and surface flaws. These sensors gather three-dimensional data of parts, compare it with design specifications, and detect even the slightest surface imperfections. Coupled with AI, the system can identify issues like micro-cracks, ensuring automotive safety and quality standards are met.

3. Food Packaging Inspection

In the food industry, TOF technology helps inspect the dimensions, shapes, and seal integrity of food packaging. With AI assistance, it quickly identifies packaging defects, such as loose seals or damage, reducing the chances of faulty products reaching consumers and ensuring brand integrity and food safety.

4. Pharmaceutical Packaging Quality Control

In pharmaceutical manufacturing, TOF technology ensures that drug packaging and bottles meet strict standards for size and sealing. Combined with AI algorithms, the system can verify label placement, cap sealing, and detect minor defects in packaging. This ensures that pharmaceutical products meet high-quality standards for safety and compliance.

Conclusion

TOF technology, integrated with AI visual inspection algorithms, offers unparalleled precision and efficiency in production line quality control. By automating inspection processes, reducing human intervention, and delivering stable performance under diverse environmental conditions, TOF sensors help maintain high product quality. As these technologies evolve, TOF will play an increasingly pivotal role in advancing smart manufacturing and quality control, leading industries toward more efficient, precise, and intelligent production systems.

Synexens Industrial Outdoor 4m TOF Sensor Depth 3D Camera Rangefinder_CS40p

BUY IT NOWhttps://tofsensors.com/collections/time-of-flight-sensor/products/synexens-industrial-outdoor-tof-sensor-depth-3d-camera-rangefinder-cs40-pro

After-sales Support:

Our professional technical team specializing in 3D camera ranging is ready to assist you at any time. Whether you encounter any issues with your TOF camera after purchase or need clarification on TOF technology, feel free to contact us anytime. We are committed to providing high-quality technical after-sales service and user experience, ensuring your peace of mind in both shopping and using our products.

- このできごとのURL:

コメント