How ToF Technology Improves Precision and Efficiency in Industrial Inspection

(2025年12月05日)— A Comprehensive Guide to 3D Depth Sensing, Automated Quality Control, and Smart Manufacturing

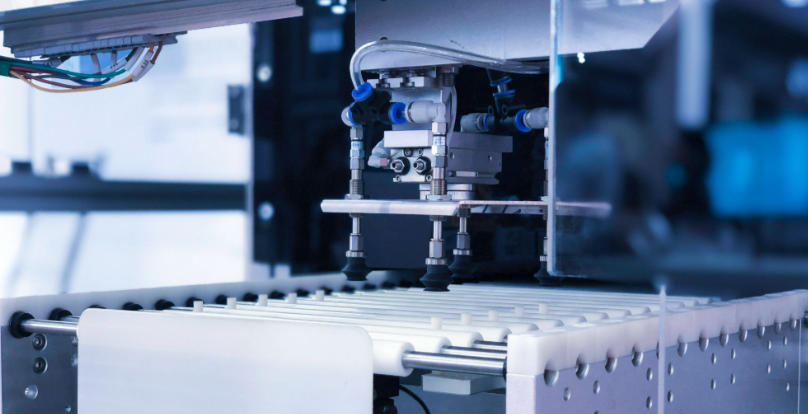

Automation Demand and the Need for High-Precision Industrial Inspection

With the rapid advancement of Industry 4.0, smart factories are moving toward fully automated production lines that require highly accurate, efficient, and consistent inspection systems. Traditional manual inspection and basic 2D vision systems struggle to meet modern industrial standards because they are:

Slow and labor-intensive

Prone to subjective errors

Sensitive to lighting conditions

Unable to capture complex 3D structures

Industries such as electronics manufacturing, automotive components, semiconductors, aerospace, CNC machining, and precision molding increasingly rely on advanced optical metrology and 3D inspection.

ToF (Time-of-Flight) depth sensing technology has therefore become a core tool in industrial quality assurance. By emitting light pulses and calculating the round-trip travel time, ToF cameras produce real-time 3D point clouds and high-precision depth maps, enabling automated dimensional measurement, defect detection, and surface inspection.

Compared with laser triangulation or 2D machine vision, ToF offers:

Higher speed and greater stability

High-resolution 3D measurement

Robust performance on reflective or irregular surfaces

Millisecond-level response for high-speed lines

As a result, ToF depth cameras have become essential in modern 3D metrology, smart vision systems, and industrial automation.

What Is ToF Technology Used For?

ToF (Time-of-Flight) is a 3D distance measurement and depth sensing technology widely applied in multiple industries:

1. Industrial Inspection & Quality Control

High-precision measurement, defect detection, flatness inspection, assembly validation, and 3D metrology.

2. Robotics & Autonomous Systems

3D environmental perception for AMRs, obstacle avoidance, SLAM, and robotic arm guidance.

3. Consumer Electronics

Face recognition, gesture control, AR/VR depth mapping.

4. Retail, Fitness & Virtual Fitting

Body measurement, virtual try-on, 3D scanning, product digitization.

5. Security, Smart Access & Surveillance

Human detection, pose recognition, object tracking.

6. Healthcare & Biometric Imaging

Rehabilitation monitoring, gait analysis, structure recognition.

In summary, ToF is a key technology for any system that requires real-time 3D understanding of physical space.

The Role of ToF in Industrial Quality Inspection

ToF depth cameras provide fast, non-contact, high-precision 3D measurement—ideal for modern automated quality inspection systems.

By capturing millions of depth points per frame, ToF enables:

Dimensional measurement

Defect identification

Surface quality evaluation

Real-time monitoring

Process optimization

This makes ToF fundamental for zero-defect manufacturing and smart industrial vision systems.

1. High-Precision 3D Dimensional Measurement

ToF cameras can scan objects at high frame rates and build accurate 3D depth models within milliseconds.

Typical industrial applications include:

✔ 3D dimensional inspection — length, width, height, angles, curvature

✔ Geometric tolerances — flatness, roundness, perpendicularity

✔ Sheet and pipe thickness monitoring

✔ High-speed in-line measurement on conveyor belts

✔ Robotic inspection systems for large or complex components

Compared with traditional contact gauges or CMM machines:

Non-contact and non-destructive

No mechanical wear

Suitable for fragile or soft materials

Ideal for continuous production lines

ToF also integrates seamlessly with robotic arms, cobots, AGVs, enabling flexible inspection stations.

2. Surface Defect Detection & 3D Quality Monitoring

Product performance depends heavily on surface conditions. With 3D depth perception, ToF can detect defects more effectively than 2D vision systems.

Defect types easily detected by ToF include:

Scratches, dents, pits, and cracks

Burrs or deformation in metal parts

Coating thickness variations

Misalignment during assembly

Gaps between components

ToF excels in inspecting reflective, curved, or textured surfaces, such as:

Automotive body parts

Aluminum housings

Glass, plastic, PCB components

With AI-based defect classification, ToF systems can automatically:

✔ Compare point clouds with CAD models

✔ Highlight deviations

✔ Generate 3D visualization reports

✔ Trigger alarms or robotic rejection mechanisms

3. Real-Time Feedback & Automated Control in Smart Factories

ToF enables instant digital feedback loops, the foundation of intelligent manufacturing.

How ToF strengthens production automation:

✔ Automated sorting & rejection

Immediate removal of defective items using robots or conveyors.

✔ Real-time machining correction

ToF data instantly adjusts CNC, stamping, molding, or packaging parameters.

✔ Multi-sensor fusion

Combining ToF with RGB cameras, LiDAR, thermal sensors, and structured light improves robustness.

✔ Closed-loop adaptive control

Creates a fully connected “Measure → Analyze → Optimize” ecosystem.

This real-time capability dramatically improves yield rate, production stability, and consistency.

Technical Challenges & Solutions for Industrial ToF Systems

Although ToF is powerful, industrial environments introduce challenges like reflections, ambient light, and fast-moving production cycles. The following optimizations can significantly enhance system reliability.

1. Ambient Light Interference & Optical Stability

Industrial workshops often contain strong lighting, reflective metals, and transparent materials.

Solutions:

Multi-frequency modulation to separate real signals from noise

IR narrow-band filters to minimize stray illumination

Dynamic exposure / auto-gain for stable output under varying lighting

Anti-reflection optics to reduce multi-path interference

These methods greatly improve SNR, depth accuracy, and stability.

2. Improving 3D Point Cloud Accuracy & Completeness

Complex surfaces often cause missing data or edge noise.

Best practices include:

✔ Multi-angle scanning + point cloud fusion

Reduces occlusions and improves global accuracy.

✔ AI-powered depth completion

Machine learning fills missing areas with high accuracy.

✔ Multi-frame temporal filtering

Stabilizes point clouds for dynamic scenes.

✔ Hybrid ToF + structured light or laser scanning

Combines fast scanning with micron-level precision.

These techniques significantly enhance 3D reconstruction quality for precision manufacturing.

3. Real-Time Processing & System Stability on High-Speed Lines

High-resolution ToF sensors produce large data volumes.

Performance enhancements include:

Edge computing ToF modules with embedded AI chips

FPGA/GPU acceleration for high-speed 3D processing

Distributed computing for high-volume production lines

Advanced thermal management for long-term stability

These upgrades ensure millisecond-level response, critical for automotive, electronics, and FMCG industries.

Toward a Robust ToF Industrial Inspection System

With significant advancements in optics, algorithms, and embedded computing, industrial ToF systems now offer:

Stable performance in complex lighting

High-quality 3D reconstruction on difficult surfaces

Real-time inspection and automated decision-making

ToF is becoming the backbone of digital twins, smart factories, and Industry 4.0 inspection platforms.

Recommendations for Manufacturers

1. Integrate AI for Smarter Detection

Deep learning improves accuracy for defect recognition and surface analysis.

2. Adopt Multi-Sensor Fusion

Combine ToF + RGB + LiDAR + laser triangulation for comprehensive inspection.

3. Optimize Hardware Placement & Sensor Angles

Ensure full coverage of critical detection zones.

4. Use Edge + Cloud Hybrid Architecture

Instant decision-making plus long-term data analytics.

These strategies significantly boost quality stability and production yield.

The Future: ToF + AI + Automation Leading the Next Industrial Revolution

Looking forward, ToF will deeply integrate with:

AI-driven machine vision

Robotics and autonomous manufacturing

Predictive maintenance

Digital twin inspection systems

Future ToF-based inspection will deliver:

⭐ Real-time 3D quality monitoring

⭐ Fully automated inspection workflows

⭐ Intelligent production optimization

⭐ Zero-defect manufacturing

By leveraging ToF depth sensing, manufacturers can transform their production lines into high-precision, high-efficiency, AI-driven smart factories, opening a new era of industrial quality innovation.

Synexens Industrial Outdoor 4m TOF Sensor Depth 3D Camera Rangefinder_CS40

BUY IT NOWhttps://tofsensors.com/collections/time-of-flight-sensor/products/synexens-industrial-outdoor-tof-sensor-depth-3d-camera-rangefinder-cs40

After-sales Support:

Our professional technical team specializing in 3D camera ranging is ready to assist you at any time. Whether you encounter any issues with your TOF camera after purchase or need clarification on TOF technology, feel free to contact us anytime. We are committed to providing high-quality technical after-sales service and user experience, ensuring your peace of mind in both shopping and using our products

- このできごとのURL:

コメント