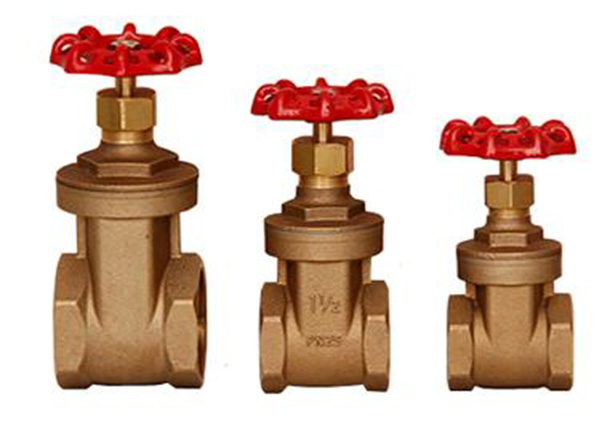

Bronze Gate Valve China Manufacturer

(2024年07月19日)https://www.carbovalve.com/products/bronze-gate-valve/

Bronze Gate Valve China Manufacturer

Bronze gate valve for sale uses bronze material, which has excellent wear resistance and corrosion resistance, good casting performance and airtightness. The bronze steam rated gate valve is widely used in higher load parts, such as bearings, pump bodies, marine spirals, petrochemical industry, shipbuilding industry, etc. According to the sealing surface configuration, the crane bronze gate valve can be divided into a wedge gate and a parallel gate. According to the thread position of the valve stem, it can be divided into an open stem small gate valve and a dark stem gate valve. The open-stem bronze American standard gate bronze valve, the concealed bronze American standard gate valve, the opening and closing part of the American standard bronze gate valve is the gate. The movement direction of the gate is perpendicular to the direction of the fluid, so the American standard union bonnet gate valve can only be fully opened or fully closed. I can't adjust and throttle.

Bronze Gate Valve Details:

Low flow resistance.

Less effort when opening and closing.

The medium can flow in any direction on both sides, easy to install.

Simple shape, short structure length, wide application range.

Compact structure, good valve rigidity, smooth passage, small flow resistance, long service life.

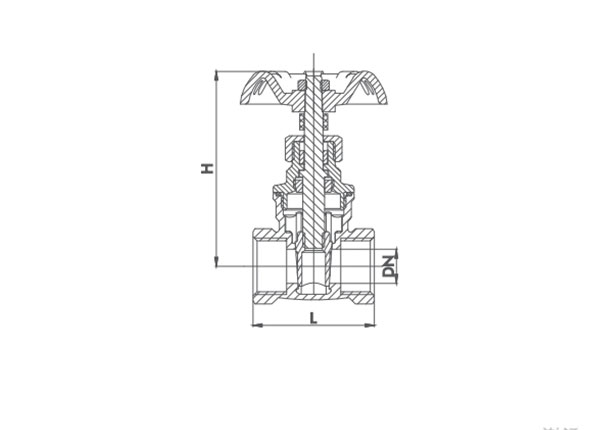

Bronze Gate Valve Specifications

MaterialPressureOperating temperatureP/NSIZEDHLH

Bronze400psi-20℃≤T≤120℃220311/2"12.74572.4

220323/4"19.25084.9

220331"255799.32

2203411/4"3264120.7

2203511/2"38.166138

220362"5073160.5

Why Choose Carbo As Your Bronze Gate Valve Supplier

1

If you are in need of high-quality bronze gate valves, Carbo bronze gate valve factory is the ideal choice for you. Our bronze gate valve China company offers a range of benefits that make us stand out from our competitors, including:

2

Quality bronze gate valve: Our bronze gate valves are manufactured to meet the highest industry standards, ensuring reliable and durable performance.

3

Customization bronze gate valve options: Carbo bronze valve manufacturer offer customization services to meet your specific requirements and ensure that our valves are tailored to your unique application.

4

Competitive bronze gate valve price list: Carbo bronze gate valve china manufacturer offer competitive pricing without compromising on quality, ensuring that you get the best value for your investment.

5

Fast delivery: We understand that time is of the essence, and Carbo bronze valve supplier strive to deliver our bronze gate valves quickly and efficiently to meet your project timelines.

6

Expert support: Our experts team of china gate valve is always available to provide technical support and assistance to ensure that you get the best possible solutions for your industrial needs.

7

Choose Carbo bronze gate valve suppliers and bronze gate valve manufacturers as your bronze gate valve supplier and experience the benefits of working with a reliable and trusted partner in the industry.

Bronze Gate Valve FAQs

What is the bronze gate valve application?

A gate valve is a kind of copper gate valve that opens and closes. The gate moves in a perpendicular direction to the fluid flow. The gate valves for sale can only be fully opened and fully closed. The gate valves are classified as stiff gate valves or flexible gate valves based on the difference in the gate. Chemical, petroleum, light industrial, hospitals, environmental protection, and other areas all use it.

Reference: What Is a Gate Valve? What Are Its Functions?

Bronze Gate Valve FAQsWhat are different types of gate valves?

According to the gate structure, the gate valve types are divided into wedge type and parallel type. There are three types of wedge gates: single gate, double gate and elastic gate. According to the different structure types, the gate valve is divided into flat gate and knife gate valves.

Reference: How to Classify Types of the Gate Valve?

Bronze Gate Valve FAQsWhat is difference between gate valve and globe valve?

Steam rises when the shut-off valve is opened or closed. To put it another way, when the handwheel is spun, the handwheel rotates and lifts with the stem. The gate valve turns the handwheel to move the valve stem up and down, while the handwheel's position remains constant. Compared with bronze globe valve, the gate valve also has only two states: fully open or fully closed, has a big opening and closing stroke, and takes a long time to open and close.

Reference: Bronze Ball Valve vs. Bronze Globe Valve vs. Bronze Gate Valve

Advantages of Using Bronze Gate Valves Compared to Other Materials

Bronze gate valves offer several advantages over other materials, making them a popular choice in various applications. Here are some key advantages:

a. Corrosion Resistance: Bronze gate valves are highly resistant to corrosion, particularly in marine and corrosive environments. This property ensures their durability and longevity, reducing the need for frequent replacements.

b. High Strength and Durability: Bronze gate valves exhibit excellent strength and durability, allowing them to withstand high-pressure and high-temperature conditions. This makes them suitable for demanding industrial applications.

c. Thermal Stability: Bronze has good thermal stability, meaning it can handle temperature variations without compromising its structural integrity. This property is crucial in applications where temperature fluctuations are common.

d. Easy Machinability: Bronze is relatively easy to machine, making it a favorable material for valve manufacturing. It allows for precise shaping and forming of intricate valve components, resulting in reliable and efficient gate valves.

e. Wide Range of Applications: Bronze gate valves are versatile and can be used in a wide range of applications, including plumbing systems, HVAC (Heating, Ventilation, and Air Conditioning), oil and gas, water treatment, and more. Their adaptability to various industries is a significant advantage.

f. Excellent Sealing Capability: Bronze gate valves provide a tight and reliable seal when closed, preventing leakage and ensuring efficient flow control. This characteristic is essential in applications where fluid leakage can lead to safety hazards or operational inefficiencies.

g. Low Friction: Bronze gate valves typically exhibit low friction between moving parts, allowing for smooth operation and reduced wear. This results in improved efficiency and longevity of the valve.

h. Compatibility with Different Media: Bronze gate valves are compatible with a wide range of media, including water, oil, gas, and many chemicals. This versatility makes them suitable for diverse applications.

Key Considerations When Selecting a Bronze Gate Valve for a Specific Application or Industry

When selecting a bronze gate valve for a specific application or industry, several key considerations should be taken into account. These considerations help ensure that the chosen valve meets the requirements and performs optimally. Some important factors to consider are:

a. Pressure and Temperature Ratings: Evaluate the maximum pressure and temperature conditions the bronze gate valve will be exposed to. Choose a valve that has appropriate ratings to handle the specific operating conditions without failure.

b. Valve Size and Flow Capacity: Determine the required valve size based on the flow rate and pipe diameter of the system. Ensure the selected bronze gate valve can handle the desired flow capacity without causing excessive pressure drop.

c. End Connection Type: Consider the type of end connection (e.g., threaded, flanged) required to integrate the bronze gate valve into the existing system or pipeline. Verify that the chosen valve has compatible end connections.

d. Application Specifics: Take into account the specific application requirements, such as the type of media (liquid, gas, or slurry), the presence of abrasive particles, and any special conditions or regulations applicable to the industry.

e. Operational Considerations: Evaluate the operational requirements, such as the frequency of operation, need for manual or automated control, and accessibility for maintenance and repair.

f. Compliance and Certifications: Check if the bronze gate valve manufacturer, such as a Carbo bronze gate valve manufacturer in China, adheres to relevant industry standards and certifications. Ensure the valve meets specific regulatory requirements for the intended application or industry.

g. Reputation and Quality: Consider the reputation and quality of the bronze gate valve manufacturer or China bronze gate valve factory. Look for manufacturers with a track record of producing reliable and high-quality valves.

h. Budgetary Constraints: Factor in the budget allocated for the valve procurement. Compare the pricing and value offered by different manufacturers while keeping in mind the importance of quality and reliability.

By considering these key factors, you can select a suitable bronze gate valve that meets the requirements of your specific application or industry. For detailed information about a Carbo bronze gate valve manufacturer or a China bronze gate valve factory, it is recommended to directly contact the manufacturer or visit their website for the most accurate and up-to-date information.

Why Choose Bronze Gate Valves from a Chinese Factory/Manufacturer?

1. Cost-Effectiveness

Competitive Pricing: Chinese manufacturers often offer more affordable prices due to lower production costs, making bronze gate valves from China a cost-effective option without compromising quality.

Economies of Scale: Large-scale production capabilities in China allow factories to reduce per-unit costs, passing savings onto customers.

2. Quality and Standards

Adherence to Standards: Many Chinese factories comply with international standards such as ISO, API, and ANSI, ensuring their products meet global quality benchmarks.

Advanced Manufacturing Techniques: Chinese manufacturers increasingly use advanced technology and precision engineering to produce high-quality valves.

3. Customization and Flexibility

Tailored Solutions: Chinese manufacturers often offer customizable solutions to meet specific requirements, including different sizes, pressure ratings, and material specifications.

Rapid Prototyping: Fast turnaround times for prototypes and custom designs allow for quicker project initiation and completion.

4. Broad Range of Products

Diverse Selection: Chinese factories typically offer a wide range of bronze gate valves, catering to various industries and applications, from plumbing to industrial uses.

Availability: High production capacity ensures that a broad inventory is readily available, reducing lead times for orders.

5. Technological Advancements

Innovation: Continuous investment in research and development has led many Chinese manufacturers to innovate and improve their valve designs, enhancing performance and reliability.

Modern Equipment: Utilization of state-of-the-art machinery and equipment ensures precision and consistency in manufacturing.

6. Strong Supply Chain

Robust Infrastructure: Well-developed logistics and supply chain networks in China facilitate efficient production and timely delivery of products worldwide.

Global Reach: Many Chinese manufacturers have established global distribution networks, ensuring easy access and support for international customers.

7. Reputable Manufacturers

Established Companies: Numerous Chinese valve manufacturers have built strong reputations over the years, known for delivering reliable and durable products.

Customer Support: Comprehensive customer service, including technical support and after-sales services, enhances the purchasing experience.

8. Economic Growth and Investment

Industrial Hub: China’s significant investment in industrial infrastructure has made it a leading hub for manufacturing high-quality industrial products, including bronze gate valves.

Government Support: Supportive policies and initiatives by the Chinese government bolster the manufacturing sector, ensuring continuous improvement and competitiveness.

9. Sustainability Initiatives

Environmental Compliance: Increasing focus on sustainable manufacturing practices and compliance with environmental regulations ensures that products are eco-friendly.

Green Manufacturing: Adoption of green technologies and processes minimizes the environmental impact of production.

- このできごとのURL:

コメント