Bronze Globe Valve Factory

(2024年07月20日)https://www.carbovalve.com/products/bronze-globe-valve/

Bronze Globe Valve Factory

The closing component (disc) of a bronze globe valve rotates along the centre line of the valve seat. According to this valve disc movement form, the change in the valve seat port is proportional to the valve disc stroke. This type of bronze valve is ideal for flow control because the opening or shutting stroke of the valve stem is relatively short. It has a very dependable cut-off function. The change of the valve seat port is proportional to the stroke of the valve disc. As a result, this sort of globe valve for sale is ideal for usage as a shut-off, adjustment, or throttling valve. There are three bronze globe valves types in Carbo globe valve suppliers and bronze globe valve manufacturers: straight-through bronze globe valves, right-angle bronze globe valves and direct-flow oblique globe valves.

Bronze Globe Valve Details:

Simple structure, convenient manufacturing and maintenance.

Small working stroke, short opening and closing time.

Good sealing performance, small friction between the sealing surfaces, long service life.

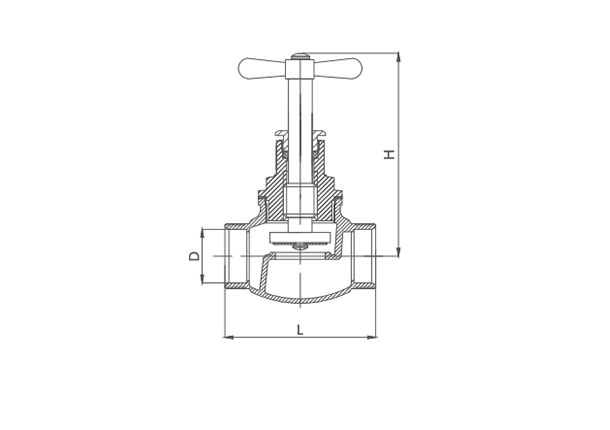

Bronze Globe Valve Diagram

CB-5510 Globe Valve

CB-5511 Globe Valve

Bronze400psi-20℃≤T≤120℃551111/2"121118

551123/4"126118

551131"130123

FAQs About Bronze Globe Valve

What is the globe valve application?

Globe bronze valve is ideal for flow control because the opening or shutting stroke of the valve stem is relatively short. It has a very dependable cut-off function. The change of the valve seat port is proportional to the stroke of the valve disc. As a result, this globe valves are used for flow control as a shut-off, adjustment, or throttling valve.

Reference: Advantages, Applications, and Benefits of Brass Globe Valves

What is the difference between globe and ball valve?

Because the shut-off valve is a forced-sealing valve, pressure must be applied to the disc when the copper globe valve is closed to prevent the sealing surface from leaking. The bronze globe valve's opening and closing mechanism is a ball that revolves around the axis of the valve and is driven by the valve stem. This kind of China bronze ball valve is most commonly utilized to modify and control fluid media.

Reference: Bronze Ball Valve vs. Bronze Globe Valve vs. Bronze Gate Valve

What is the globe valve working principle?

The sealing surface is less mechanically worn. When sealing the components, removing the entire valve from the pipeline is unnecessary, which is ideal for situations when the bronze globe valve and pipeline are welded together. Because the medium's flow direction has shifted through this type of valve, the flow resistance of the stop valve is more excellent than that of other valves.

Bronze Globe Valve Working Principle

The working principle of a bronze high pressure globe valve involves the movement of a disc or plug inside the valve body to control the flow of fluid. Here are the key steps in the working of a bronze globe valve:

When the valve is in the closed position, the disc or plug is pressed against the valve seat, blocking the flow of fluid. This ensures a tight seal and prevents leakage.

To open the valve, the stem connected to the disc is rotated or threaded, causing the disc to lift away from the seat. This creates a pathway for the fluid to flow through the valve.

The degree of opening or closing can be adjusted by rotating the stem, allowing for precise flow control. As the stem is turned, the disc moves closer to or farther away from the seat, regulating the flow rate accordingly.

When the valve is fully open, the disc is lifted completely away from the seat, providing a maximum flow area and minimizing pressure drop.

To close the valve, the stem is rotated or threaded in the opposite direction, causing the disc to move downward and come into contact with the seat. This blocks the flow of fluid and ensures a tight seal.

The working principle of a bronze globe valve allows for reliable control of fluid flow, making it suitable for various applications where precise regulation is required.

Are Bronze Globe Valves Suitable for Both High-Pressure and Low-Pressure Applications

Bronze globe valves are versatile and can be used in a wide range of pressure applications. Whether they are suitable for high-pressure or low-pressure applications depends on several factors. Here are some considerations:

a. Material and Design: Bronze globe valves are typically made from durable and corrosion-resistant materials, such as bronze or brass. The choice of material and valve design can determine the pressure rating and suitability for different pressure ranges.

b. Valve Class and Rating: Bronze globe valves are available in different classes and pressure ratings, such as Class 150, Class 300, or PN16. These classifications indicate the maximum pressure levels that the valves can handle. It is essential to select a bronze globe valve with the appropriate class and rating for the desired pressure application.

c. Valve Size and Configuration: The size and configuration of the bronze 2 inch globe valve, 4 inch globe valve also play a role in determining its suitability for different pressure applications. Larger-sized valves are generally more capable of handling higher pressures.

d. Industry and Application Requirements: The specific industry and application requirements should be considered when determining the suitability of bronze globe valves for high or low pressure. Certain industries or applications may have specific pressure guidelines or regulations that need to be followed.

It is important to consult with a reputable bronze globe valve factory or bronze valve manufacturer, such as Carbo bronze globe valve manufacturers in China, to ensure that the chosen valves meet the required pressure specifications. OEM globe valve manufacturers in China can also provide customized solutions for specific pressure applications.

- このできごとのURL:

コメント