SLA Printing

(2022年10月10日)https://www.gjprototyping.com/sla-parts-service/

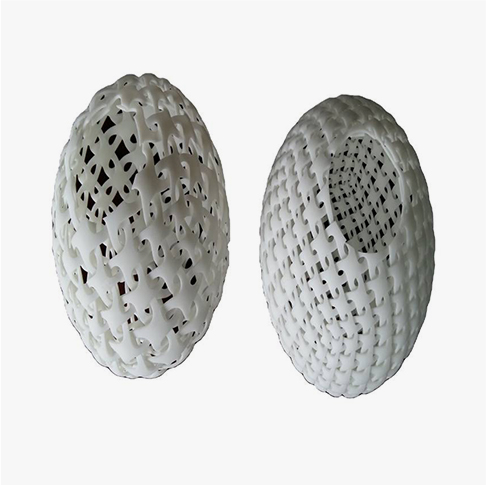

SLA is focused on the surface of a light cured material, which is solidified from point to line and line to surface. SLA plastic 3d printing enables a wide selection of materials, extremely high feature resolution and high quality surface treatment.

Types of SLA Printing

3D ABS Printing

3D printed ABS is suitable for full functional models. It has 80% of the strength of injected molded ABS. Layer thickness 0.13 – 0.25 mm. 3D printed ABS is a strong, hard, waterproof functional part, and Somos 14120 resin material in an opaque white color, similar to engineering materials.

PETG Plastic 3D Printing

Petg Plastic 3d Printing Product size precision is excellent, with precision and durability characteristics of ABS materials, with good water resistance, the durability of the parts is good, can be processed into translucent or transparent state according to the actual demand.

Hdpe 3D Printing

HDPE is a soft, rubber-like material that is ideal for modeling precision parts. "These materials help users to be more flexible in handling and testing flexible parts and prototypes while providing excellent precision, fine detail, and enhanced product authenticity."

Polycarbonate 3D Printing

Polycarbonate has strong deformation resistance at high temperature. And It is Light and transparent thermoplastic with a Rockwell hardness of R 121Carbonate-printed . 3D parts will be strong and stiff.

SLA 3D Printing Process

Step One

The tank is filled with liquid photosensitive resin, which solidifies quickly when exposed to a uv laser beam emitted by the laser .

Step Two

At the beginning of molding, the lifting table is below the liquid level, just a height of the cross-section layer thickness.

Step Three

Through the laser beam focused by the lens, the section profile is scanned along the liquid level according to the machine instructions.

Step Four

The table drops the height of one layer of section layer thickness and solidifies the other layer of section.

Advantages of 3D SLA Resin

01

After a Long development time, mature process, widely used. Uv curing molding systems account for about 60% of the rapid forming machines installed worldwide.

02

The molding speed is fast and the system works stably.

03

Highly flexible.

04

High precision, can be done micron level, such as 0.025mm.

05

Good surface quality, relatively smooth,suitable for fine parts.

As one of SLA 3d printing companies, we can offer kinds of 3d prototype printing services for clients, if you have needs, please contact us.

If you want to know more about product design prototype, please visit our website.

- このできごとのURL:

コメント