Project Management Digitalisation Key to Tackle Cash Flow Challenges

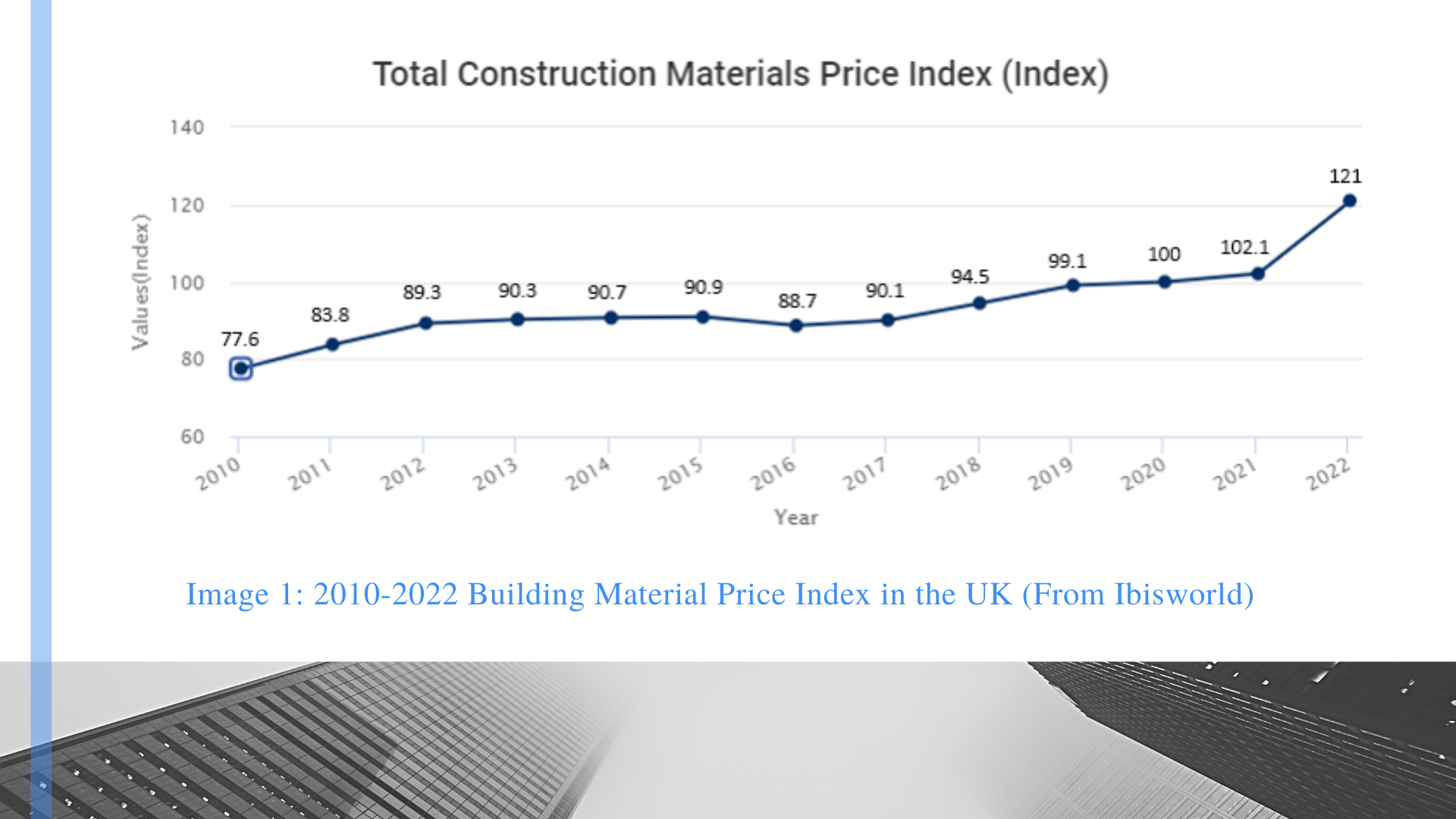

(2023年12月04日)The construction industry is confronting unprecedented challenges, the biggest of which is the ever-tightening cash flow. You could get a glimpse of the larger picture of Europe through the labour and material price statistics in the UK. Due to supply chain disruption caused by the pandemic, rising energy prices thanks to the Russia-Ukraine conflict, and tariff and non-tariff barriers to trade caused by Brexit, the UK building material price index has been surging since 2019. Until 2022, it reached the highest level in 12 years (121). Additionally, the labour cost indices of the industry rushed to the highest point among 5 years in 2021 Q3 as well.

Usually, there are two ways to increase cash flow, increase income and reduce cost, respectively. However, the global economic downturn limits the increase of total project numbers and revenue by undertaking more projects, which means reducing costs now plays a more significant role in the current economic environment.

Benefits of Project Management Digitalisation on Costs

The key to reducing cost is to improve project management capability. Firstly, it means rework and waste will be significantly reduced. Rework incurs additional time, costs, materials, and labour. Reducing rework is beneficial to lowering costs. Secondly, it increases work efficiency, including maintaining a streamlined and efficient workflow and increasing productivity and accountability. Last but not least, improved project management offers robust risk control in safety, progress, and supply chain. Risks not detected and not handled in time will pose a great danger and leads to significant losses in life and finance.

Then how to improve project management capability? Digital transformation is the answer. Technologies and data do empower projects’ cost reduction and efficiency. However, there are still some common misunderstandings about digitalisation.

Misunderstandings and Essence of Digitalisation

The first common misunderstanding is that people only pay attention to the ‘tip of the iceberg’. Digitalisation is a systematic project. In practice, many companies pay more attention to data display (tip of the iceberg) but overlook the importance of data generation, integration, and analysis (larger part underwater). Data is an 'ore' that needs to be extracted to keep the essence. Enterprises should build effective analysis systems so that there is a solid foundation behind data display.

The second usual misunderstanding is reversed investment priorities. There are two directions when a digital construction company invests in digitalisation, operational digitalisation, and core business digitalisation. The former includes HR, finance, IT, etc., while the latter focuses on the projects. Apparently, the projects are real income sources, providing the primary value to the company. Digitalisation of core business will drive the overall enterprise development. However, many companies do not see it and put too many resources into operational digitalisation, resulting in reversed investment priorities.

Research by McKinsey Consulting shows that the failure rate of digital transformation in construction for general enterprises is extremely high. The main reason for it lies in the failure to recognise the essence of digitalisation — data and connection.

Real-time, accurate, unmodified data is the basis for establishing a reliable connection with clear responsibilities. With the advancements of technologies such as AI, this goal can be achieved automatically with minimum cost. And connection means not just technical connections. The ultimate goal of connection is to realise a reliable business connection with clear responsibilities and rights. In this regard, enterprises in transition must grasp the 'fineness' of data connection. In simple terms, the fineness of data connection is the smallest unit of management involved. For example, the management unit in project management should go into details such as quality, safety, documentation, and progress instead of just focusing on contract settlement data. In addition, all these fineness data should be interconnected, for only the connected data can link each part of the project into a wholeness, facilitating collaboration and driving efficiency.

Advice on Digitization of Project Management

There are two most important aspects to consider before implementing any digital systems.

The first is to have an integrated system rather than multiple software for solving different problems. Companies often encounter obstacles in implementing digital software for the project team, as they find it difficult to change their original habits and to adopt new technologies, which are likely to cause reworks and increase their workload. Moreover, when more software is adopted, the data becomes scattered as the data cannot be interoperable. It would be a challenge for project managers and senior production managers to make decisions based on the data from each software than having all information integrated, displayed, and ready at the same time, reducing the real value the digital system can bring.

For instance, the issues/quality defects found during construction are recorded and tracked with Excel, emails, or other software. Drawings and design problems, such as RFI or change orders, are being communicated with document management software. The information is stored in multiple places, but the defect records or other inspection sheets, such as checklists, and weekly reports, also form part of the project documents and should be compiled easily and ready for handover.

Another example for project and production managers is that understanding various information and data is often necessary to make the most appropriate decisions. If the information is scattered or omitted, it is easy to make a deviation in the decision-making. For example, deciding whether the current progress schedule should be adjusted requires an explicit awareness of the current situation, such as materials supply, labour, and any outstanding RFIs or pending drawing-related issues.

Therefore, a well-integrated system should cover more than just the core area of the project, such as quality, safety, production and document management. For other businesses or works, the system should have an open platform to provide SAAS applications and connect with other product solutions or services, eliminate data silos, and achieve digital transformation. But also, the data between different modules/applications should be standardised and unified to ensure internal data channelling.

The second is to realise the business change during the enterprise's digital transformation. It is necessary to focus on management issues before thinking about digitalisation. For enterprises, it is essential to strengthen the management responsibility consciousness of each business and team leader and boost the management capability to promote transformation.

With digital systems, the senior managers and project managers should also monitor the quality of the data captured from the project. Otherwise, the result comes out way mislead the decision makings. For example, traditionally, the data are collected manually from the site and processed into dashboards and charts in the report for the management team to review. To make authentic decisions, the managers need to ensure there is constant valid data input from the site, otherwise, the system would be useless.

From Aaron WU, Glodon Digital Construction Product Director

If you want to know more details of construction collaboration software, please visit our website.

Established in 1998, Glodon Company Limited was listed on the A-share market in May 2010 (abbreviated as Glodon, Stock Code: 002410) in China, being the first listed company in the field of construction engineering informationization in China.

- このできごとのURL:

コメント