Automotive Pipe Fittings

(2023年)https://www.goldenlaser.org/automotive-pipe-fittings/

Laser Cutting-Machine In Automotive pipe fittings

Higher yields, higher quality, and less energy-consuming under Golden Laser tube laser cutting system.

As we all know, the selection and manufacture of automotive pipe fittings are difficult. In order to ensure the safety of drivers, they must be accurate and metal tube materials must have good process performance. Such as muffler, cowl crossbar, chassis pipe and other parts in the automobile structure need to be cut and bent during the manufacturing process. Therefore, the high-precision laser pipe cutting machine for processing automotive pipe fittings is the best choice.

What are our client tube processing requirements

1. Automated production and processing, unattended.

2. Round tube with diameter 35-70MM

3. Truncation and opening

4. Fast cutting, deburring, and high precision.

5. Short tailings

6. Cutting roundness to a perfect circle

7. Pipe seam avoidance

8.Need to be rounded

Laser Tube Cutting-Machine In Automotive pipe fittings

Muffler

A muffler is a device for reducing the noise emitted by the exhaust of an internal combustion engine—especially a noise-deadening device forming part of the exhaust system of an automobile.

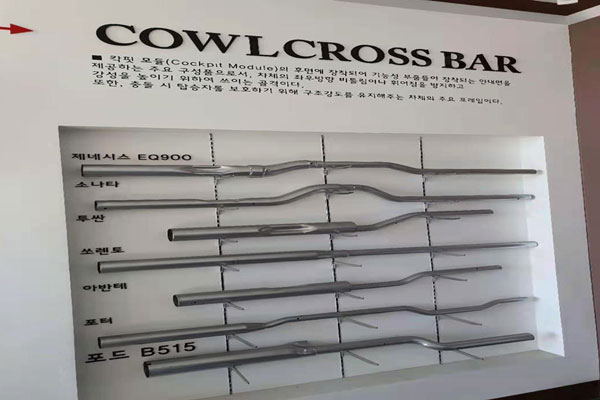

Cowl Cross Bar

Nowadays, more lightweight designs is the key goal of all major automotive industries. One of the main sections for more lightweight automotive area is the Cowl cross bar (CCB) assemblies.

Chassis Pipe

Tube chassis is a type of automobile construction chassis that is similar to the body-on-frame design. Instead of a two-dimensional ladder-type structure, it consists of a strong tubular backbone (usually rectangular in cross section) that connects the front and rear suspension attachment areas.

Golden Laser- Laser solution for automotive pipe fittings

Step 1

● Matching unique auto feeder for round tube.

● Thanks to the German PA system and Lantek nesting software, it is easy to punch holes, truncation, round cutting, and the finished product with no burrs.

Step 2

The design of extended jaws can save materials for customers and ensure that the tail length is within 80MM.

Step 3

● The function of welding seam recognition can avoid laser cutting on the welding seam, which ensures the accuracy of the finished product.

● After laser cutting, the conveyor belt transfers the pipe fittings to the chamfering machine for automated manufacturing.

For more information about china pipe laser cutting machine, please feel free to contact us!

- このできごとのURL:

コメント