Electronics Company

(2024年03月28日)https://www.hairobotics.com/cases/electronics-company

PCB Complementary Material Warehouse:

7,678 Storage Locations

99.9% Picking Accuracy

Fast Return on Investment

Project Introduction

Our customer is an electronic warehouse company, which is the world's leading high-tech enterprise in the R & D, production and sales of printed circuit boards and high-end electronic materials. Its products cover multi-layer boards, class carrier boards, thick copper boards, high-frequency, double-sided/multi-layer flexible circuit boards, special material PCBs, and more. The company seeks to realize unmanned and intelligent auxiliary material warehouse. Hai Robotics solution realized a fully-automated warehouse, improving picking efficiency and increasing the number of storage locations.

Pain Points

--Low efficiency of manual picking.

--In the 4m high warehouse manual storage density is low.

--When the jig is returned to the warehouse, the data record is chaotic and it is easy to lose the jig.

Our Solution

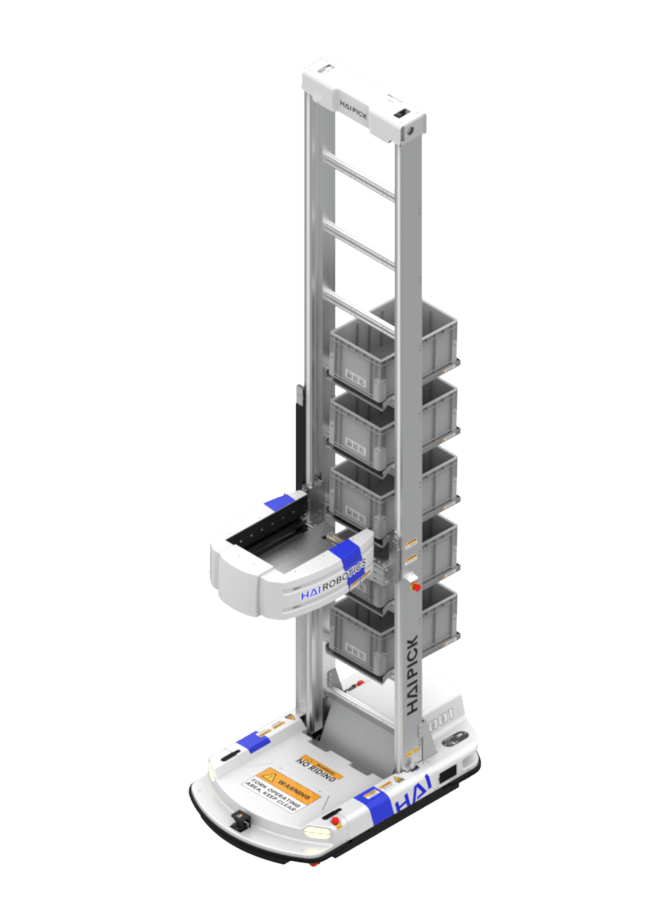

--Robot quantity & type: 4 units, A42C

--Charging stations:2 chargers

--Workstation type & quantity: 3 on-conveyor picking workstation

--Shelving height: 990mm

--Storage unit type/size: Tote 600mm(L)×500mm (W)×300mm (H); 950mm(L)×590mm (W)×230mm (H)

Customer Value

--Warehouse area: 1,100㎡, storage area: 990㎡, achieved 7,678 storage locations.

--Mixed scheduling of two models running in one warehouse at the same time.

--Realize the autonomous inbound and outbound of jigs and unmanned warehouse operations.

--Customized model to realize three-dimensional storage of super large cases

For more information about warehouse robots at work, please feel free to contact us!

- このできごとのURL:

コメント