ACR Systems

(2023年04月07日)https://www.hairobotics.com/products

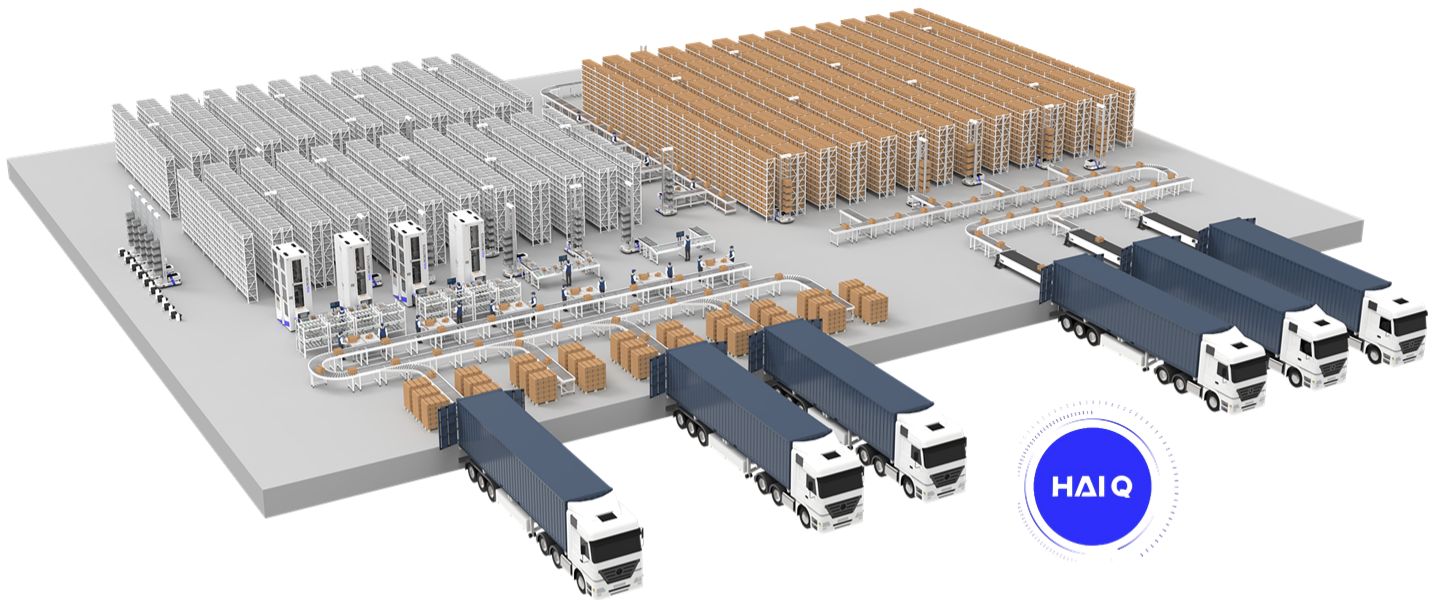

Autonomous Case-handling Robot (ACR) systems are highly efficient goods to person robots solutions designed for totes & cartons transportation and process optimization, providing efficient, intelligent, flexible, and cost-effective warehouse autonomous picking solution through robotics technology.

The HaiPick system is the world's first ACR system, incorporates HaiPick robots, Workstations and HaiQ Software Platform to perform picking, sorting, and transporting operations.

HaiPick system has been applied in Fashion, 3PL, Retail, Electronics, Healthcare, E-commerce, and other industries. Successful delivery of over 500 projects around the world.

Why Choose ACR Systems

1-2 MONTHS

Rapid deployment in 1-2 months.

( From all equipment arriving onsite to hardware installation and testing)

Respond to dynamic demands.

3-4 TIMES

Increase your operational efficiency

by 3-4 times.

400%

0.2m-10m storage range

Increase storage density by 80-400%.

Safety Protections for Human-robot Cooperation

Emergency Stop Buttons

Front/back Obstacle Avoidance

Collision Safety Device

Sound-light Alarming

HaiPick Robots

Our high-capacity ACRs provide a remarkably small footprint with a vertical reach of over 30ft high, allowing our solutions to reduce a facility’s storage footprint by up to 75%. Combined with our highly effective AI-driven software, our robotic equipment manages the efficient storage, movement of material, and workflows while improving worker efficiency.

Multi-layer ACR

The HaiPick A42 is the ACR (autonomous case-handling robot) independently developed by Hai Robotics. It can realize intelligent picking, storage and simultaneous handling of multiple cases.

Telescopic Lift ACR

The HaiPick A42T adopts a telescopic lift function independently developed by Hai Robotics, providing warehouse automation solutions with ultra-high storage density.

Fork-lifting ACR

The new HaiPick A3 adopts amr picking technology. It supports multi-form and multi-size goods picking and handling and provides mixed solutions for material turnover scenarios.

HAISTATION

In the complete Goods to Person solution, HAIPICK robots are dedicated to improving transport efficiency from warehouse to workstation. HAI ROBOTICS also developed HAISTATION, which is used to improve the efficiency of workstations to order cases.

HAIQ Software Platform

The HAIQ Software Platform is a warehouse management system developed by HAI ROBOTICS based on warehouse automation & robotics. The system introduces the concept of "workstations" and applies "goods-to-person" picking technology.

IWMS: Intelligent warehouse management system

ESS: Equipment Schedule System

HAICHARGER

Specially designed to provide intelligent charging for HAIPICK robot and ensure 7x24h operation. It can automatically detect plug-in connection, and realize remote monitoring of charging, charging station and robot.

Please do not hesitate to contact Hai Robotics for further information on the various types of warehouse robots and advanced robot solutions.

- このできごとのURL:

コメント