Maersk Contract Logistics

(2024年03月28日)https://www.hairobotics.com/cases/maersk-contract-logistics

Apparel Warehouse:

63,770 Storage Locations within 7500㎡

1,104 cases Outbound Efficiency Per Hour

99.9% Picking Accuracy

Fast Return on Investment

Project Introduction

Maersk Contract Logistics provides third-party logistics services to its partners. The distribution center handles B2B and B2C picking and delivery. The DC needs to meet the high outbound efficiency requirements to fulfill the orders. High picking efficiency and storage density are key factors in this apparel distribution automation project.

Pain Points

--Low operating efficiency.

--Various application scenarios: B2B picking / B2C picking / B2B case delivery.

--Insufficient buffer area and low storage density.

Our Solution

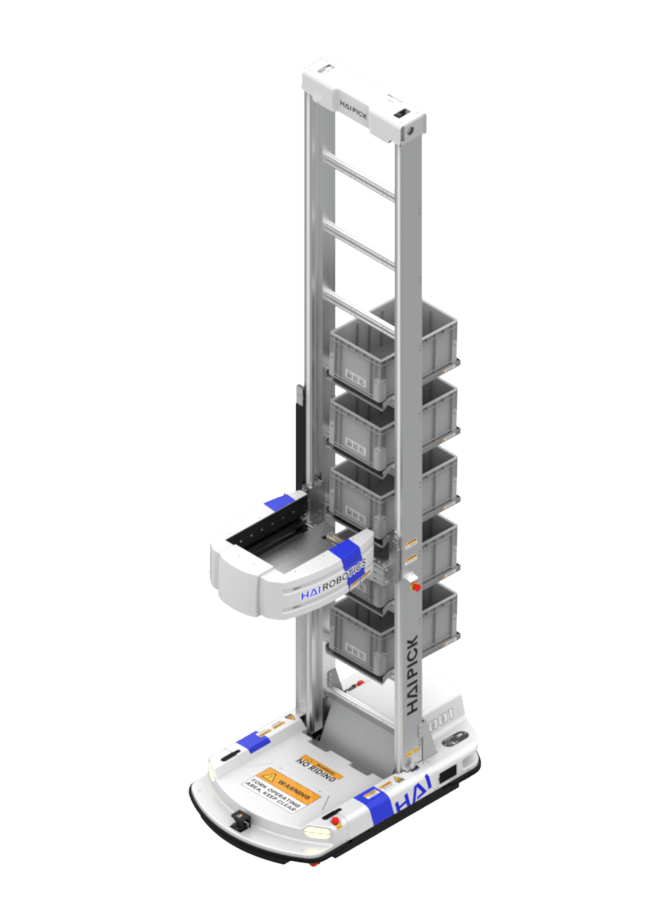

--Robot quantity & type: 49 units, A42

--Charging stations:17

--Workstation type & quantity: put to light system (2C 4, 2B 6)

--Shelving height: 4,300mm

--Storage unit type/size: tote 600mm(L)×400mm(W)×270mm(H)

Customer Value

--Shelving area: 7,500m², achieving 63,770 storage locations.

--Outbound efficiency requirement 1,104 cases/hour (7h): 263 cases/hour in B2B area and 842 cases/hour in B2C area (4 stations).

For more information about robotic automation solutions, please feel free to contact us!

- このできごとのURL:

コメント